Directional Cutting Method for Infrared Nonlinear Optical Components Prepared by Chalcopyrite-like Negative Uniaxial Crystals

A non-linear optics and chalcopyrite-like technology, applied in the direction of manufacturing tools, stone processing equipment, fine working devices, etc., can solve the problems of the operator's health, low precision, and complicated equipment, and achieve environmental benefits The effect of protection, high precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method of the present invention will be further described in the form of embodiments in conjunction with the accompanying drawings.

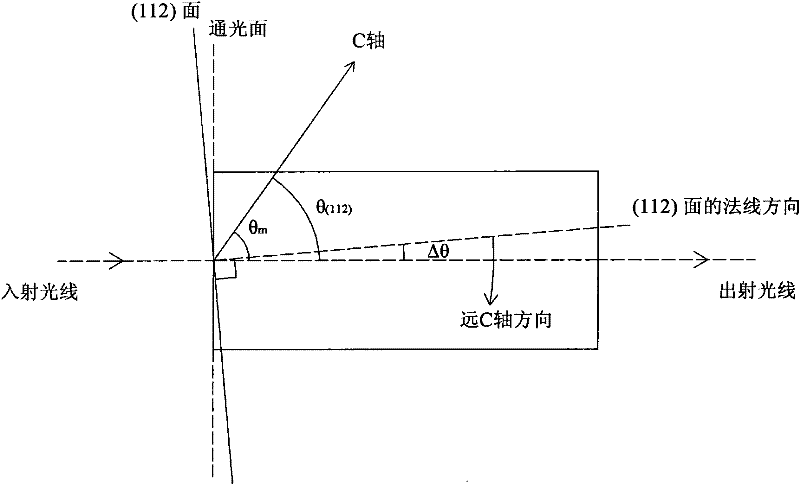

[0031] In this example, the infrared nonlinear OPO optical element is prepared with chalcopyrite negative uniaxial crystal AGIS, and its phase matching angle θm=56.0°, azimuth angle

[0032] The cleavage planes {112} and {101} are obtained through the presence of semi-open holes with uniform reflection on the surface of the AGIS crystal ingot.

[0033] In this embodiment, the steps of directional cutting are as follows:

[0034] (1) Determine the C-axis direction of the crystal

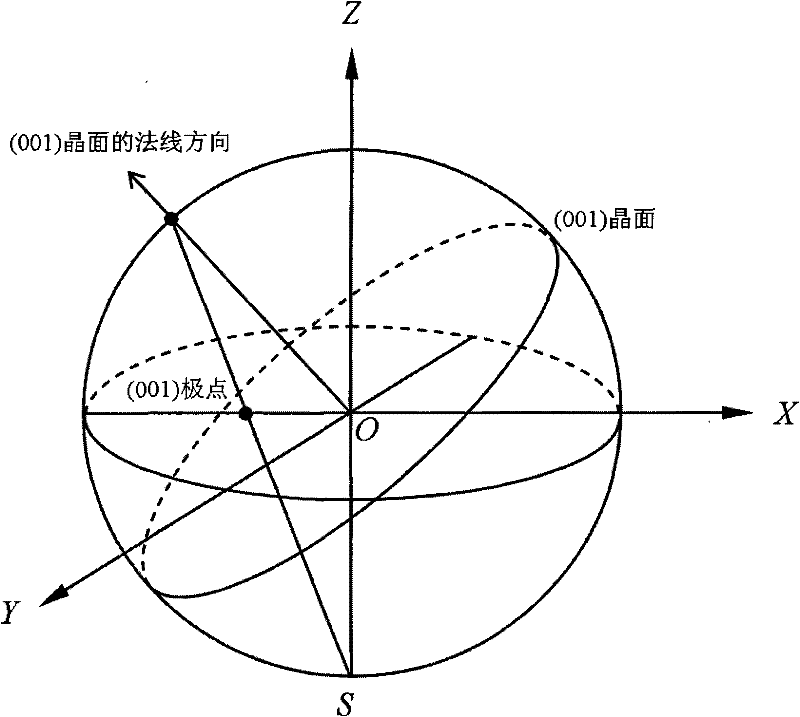

[0035] Such as figure 1 As shown, the known cleavage plane (112) of the AGIS crystal is placed at the origin position on the standard pole figure of the (112) plane of the said crystal with Wu’s grid scale, and then the crystal is rotated to place the other cleavage plane The normal direction of {101} is aligned with any pole in {101} on the standard pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com