Flat die casting method for silver bullion

A casting method and technology for silver ingots are applied in the field of flat die casting of silver ingots, which can solve problems such as appearance problems of finished silver ingots, and achieve the effects of small investment, large processing capacity and high one-time forming rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

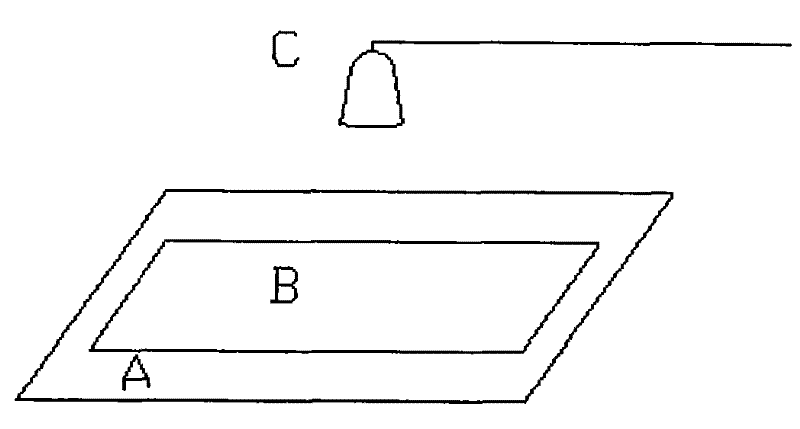

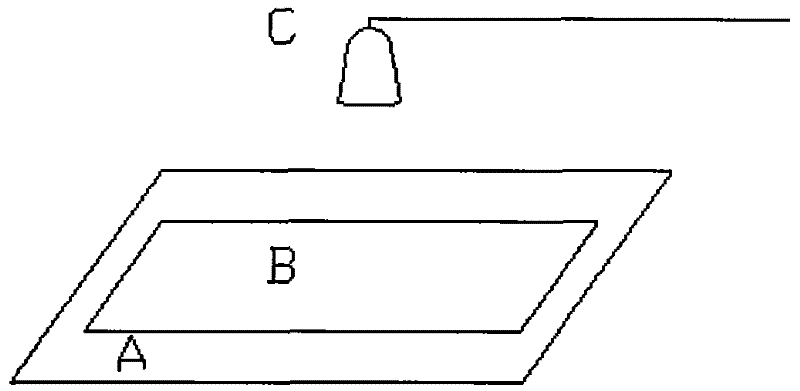

Image

Examples

Embodiment 1

[0022] Embodiment 1: a kind of method for silver ingot flat mold casting is divided into the following steps:

[0023] (1) The material is heated in a graphite crucible to a molten state by an intermediate frequency furnace.

[0024] (2) During the melting process, the material is mixed with charcoal as a reducing agent in batches. When the charcoal is burned, the oxygen in the gap of the silver powder is consumed, and the material floats on the liquid surface after melting, which not only protects the liquid surface, but also makes the dissolved oxygen part remove. Charcoal consumption is 0% to 2.5%, adding in 2 to 5 times.

[0025] (3) When the temperature of the melt reaches the casting temperature, pour it into a flat mold and cast it. After the melt fills the cavity, use flame protection.

[0026] (4) The combustible gas flame covers the cooling surface to slowly cool down the silver ingot. During this process, the high-speed airflow in the flame isolates the air and p...

Embodiment 2

[0034] Embodiment 2: first add a certain amount of charcoal at the bottom of the crucible, add the material to be processed into the crucible, and continue to add a small amount of charcoal; add a small amount of charcoal according to the situation during the process of adding materials. When the mold melt is heated to the appropriate casting temperature, it is poured into the mold, and the liquid surface is immediately protected with a gas flame until it is completely solidified. The mold needs to be preheated before use. Then soak and wash the silver ingots with dilute sulfuric acid for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com