Dual shaft structured high speed precise electric main shaft capable of performing rotation, linear reciprocating movement

A technology of linear reciprocating motion and shaft structure, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems such as the limited overhang length of the working end of the electric spindle, the inability to meet the requirements of deep hole processing, and the inability to adjust the accuracy of the spindle. Achieve the effects of shortening the suspension wall of the main shaft, safe and reliable torque transmission, and convenient installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

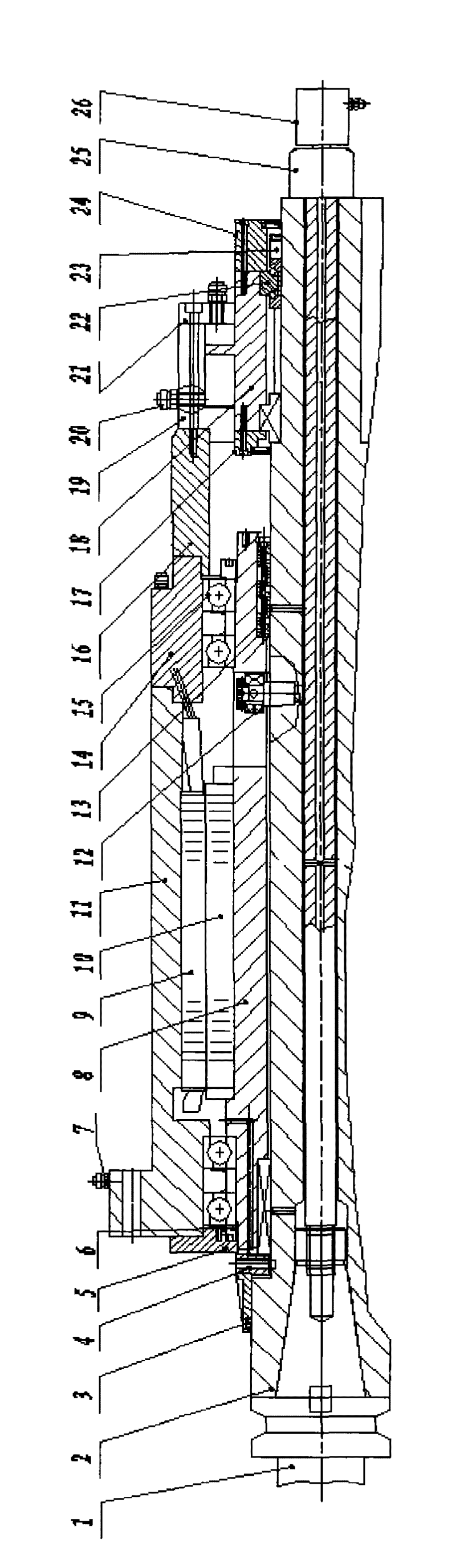

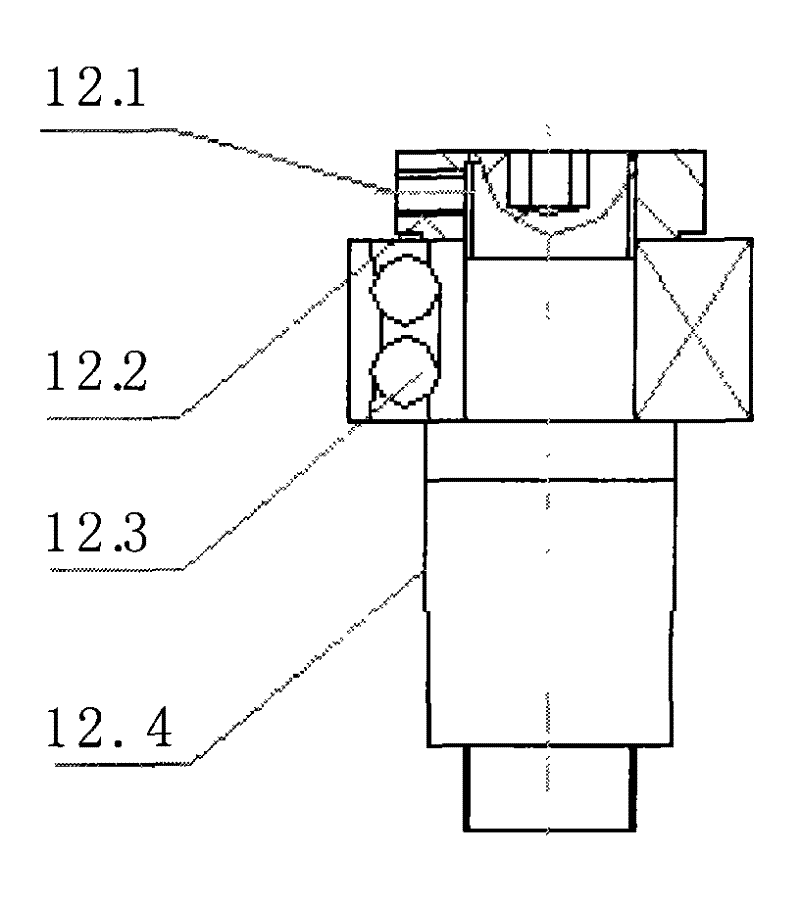

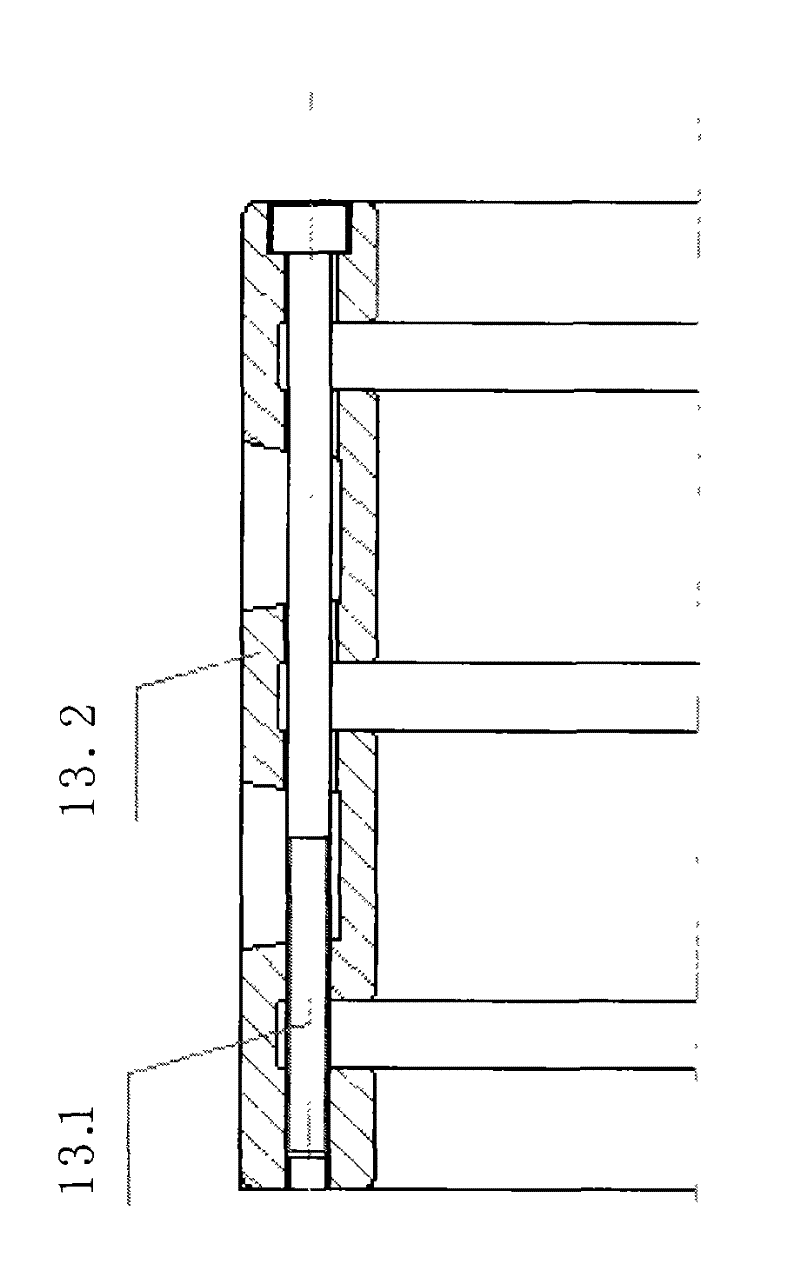

[0035] combine figure 1 , the design of the high-speed precision electric spindle with double-axis structure that can be used for rotation or linear reciprocating motion of the present invention is designed to divide the main shaft into an outer shaft (8) and an inner shaft (2), and the stator (9) and the rotor (10) Under magnetic induction, the outer shaft (8) and the inner shaft (2) realize co-rotation through the linkage pin (4) and the guide torque transmission mechanism (12), or the inner shaft (2) is driven by the oil cylinder through the guide torque transmission mechanism (12). The inner guide of the shaft (8) makes a linear reciprocating motion, and the structural design around the outer shaft (8) and the inner shaft (2) to realize the above-mentioned action requirements is as follows:

[0036] i. The outer shaft (8) is respectively installed in the corresponding positions of the housing (11) and the rear seat (14) through the front and rear bearing sets (15), and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com