Torsion vibration damper used for main reducing gear

A technology of torsional shock absorber and main reducer, applied in spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc. The effect of installation and use, improving torsional vibration and reducing adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

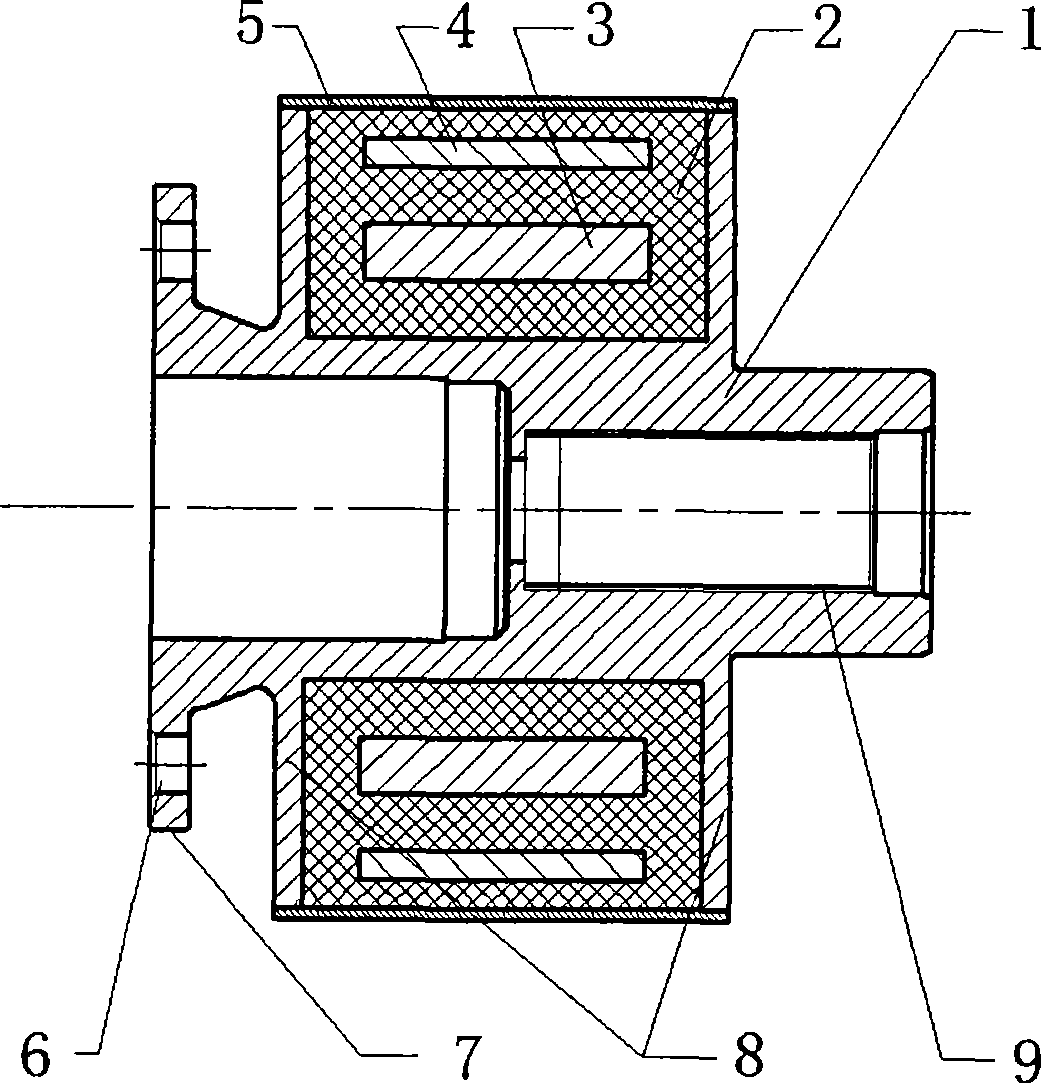

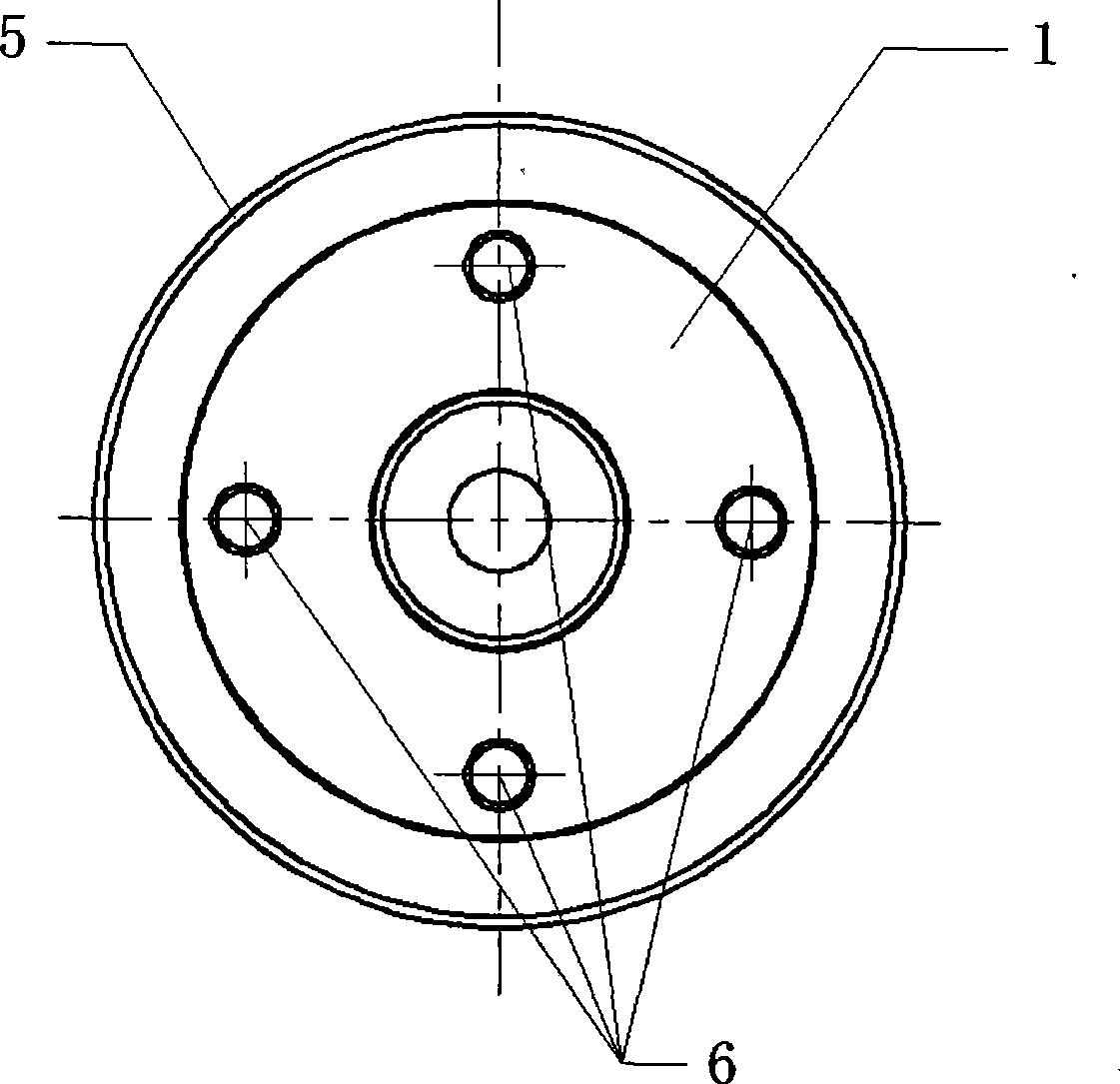

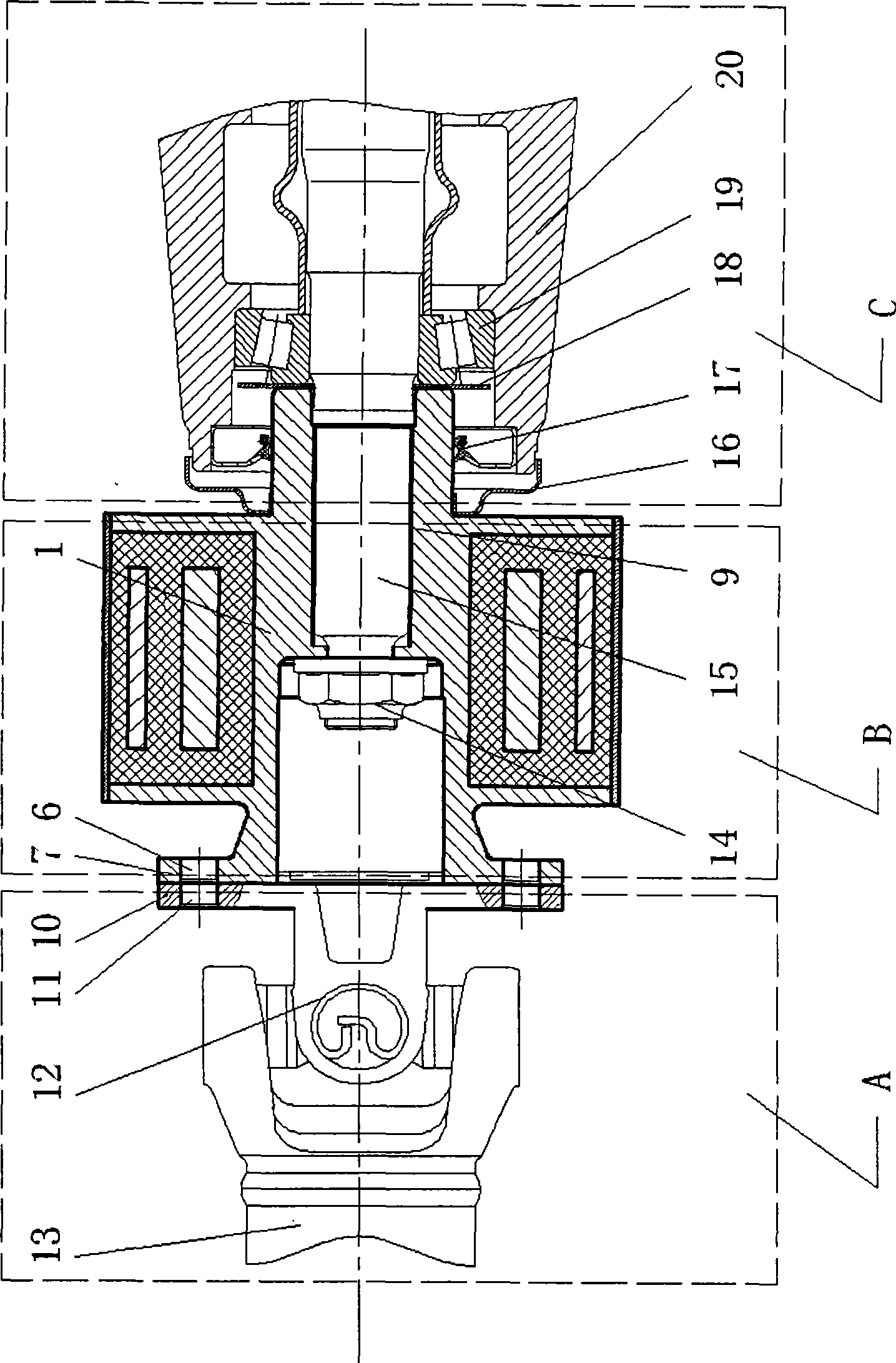

[0015] The torsional shock absorber used for the main reducer proposed by the present invention has a structure such as figure 1 and figure 2 As shown, it includes a shock absorber base 1 , a rubber layer 2 , a first mass ring 3 , a second mass ring 4 and a fixed outer ring 5 . The shock absorber base 1 is a tubular structure, the front end of the shock absorber base is a flange 7, and the flange 7 is provided with a flange connection hole 6, and the inner hole of the shock absorber base 1 is a stepped hole, and the small diameter of the stepped hole is one end Splines 9 are arranged inside, and there are axial limiting plates 8 on the outside, front and back of the shock absorber base 1 respectively. The rubber layer 2 is placed between the two front and rear axial limiting plates 8 , and the fixed outer ring 5 is sleeved on the outside of the rubber layer 2 and the two front and rear axial limiting plates 8 . The first quality ring 3 and the second quality ring 4 are wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com