Large coal bed gas recovery apparatus set

A complete set of equipment and coalbed methane technology, applied in safety devices, gas discharge, mining fluids, etc., can solve the problem of undisclosed layout and installation of gas-liquid separators in compressor units, affecting the operation stability and safety of coalbed methane recovery systems, etc. problems, to achieve the effects of easy assembly and maintenance, reduced vibration and noise, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

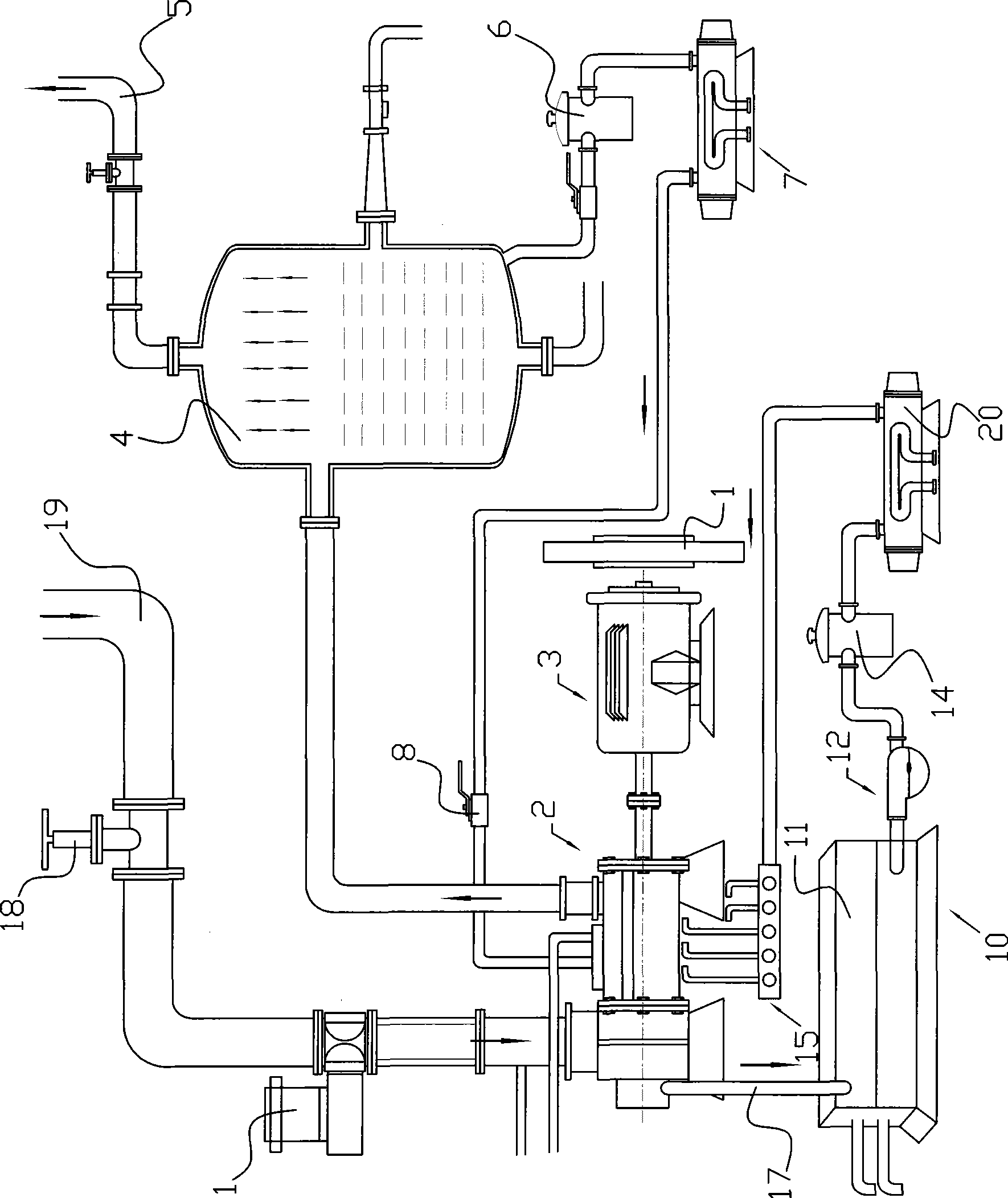

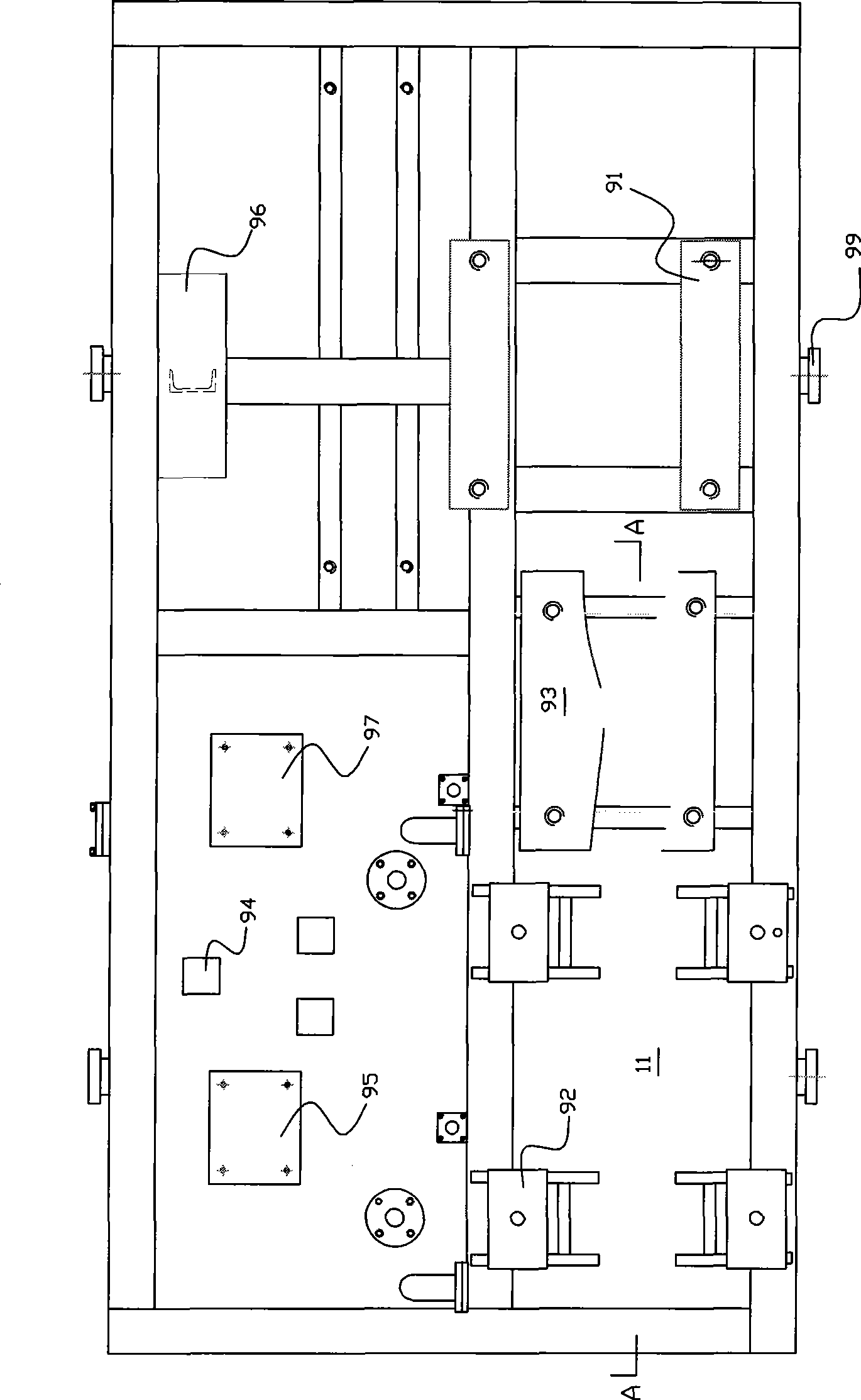

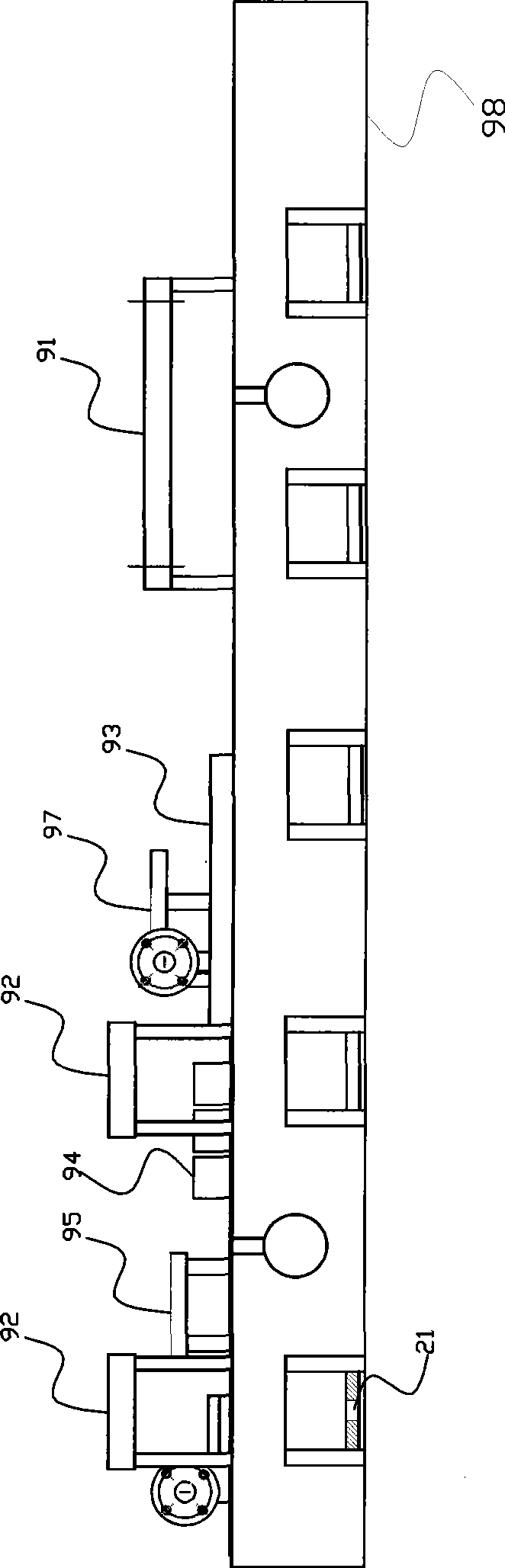

[0025] like Figure 1 to Figure 6 As shown, the large-scale coalbed methane recovery complete set of the present invention includes

[0026] an inlet butterfly valve 1;

[0027] The screw compressor unit 2 with the drive unit 3; the inlet butterfly valve 1 introduces the low-pressure coalbed methane from the mine gas source through the input pipe 19 and the switch valve 18 into the screw compressor unit 2 for compression; the output of the screw compressor unit 2 and its drive unit 3 The shafts are arranged horizontally, and they are respectively provided with a horizontal bottom plane of the compressor unit and a horizontal bottom plane of the driving unit that are parallel to their output shafts; a blower 1 with a horizontal bottom plane for heat dissipation is arranged in front of the screw compressor unit and the driving unit.

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com