Method and apparatus for preparing sulfur-free natural gas from methane

A technology for preparing equipment and natural gas, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of low purity of biogas, low utilization rate of biogas preparation raw materials, unsuitable for large-scale and high-efficiency utilization, etc. High efficiency and high purity of biogas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

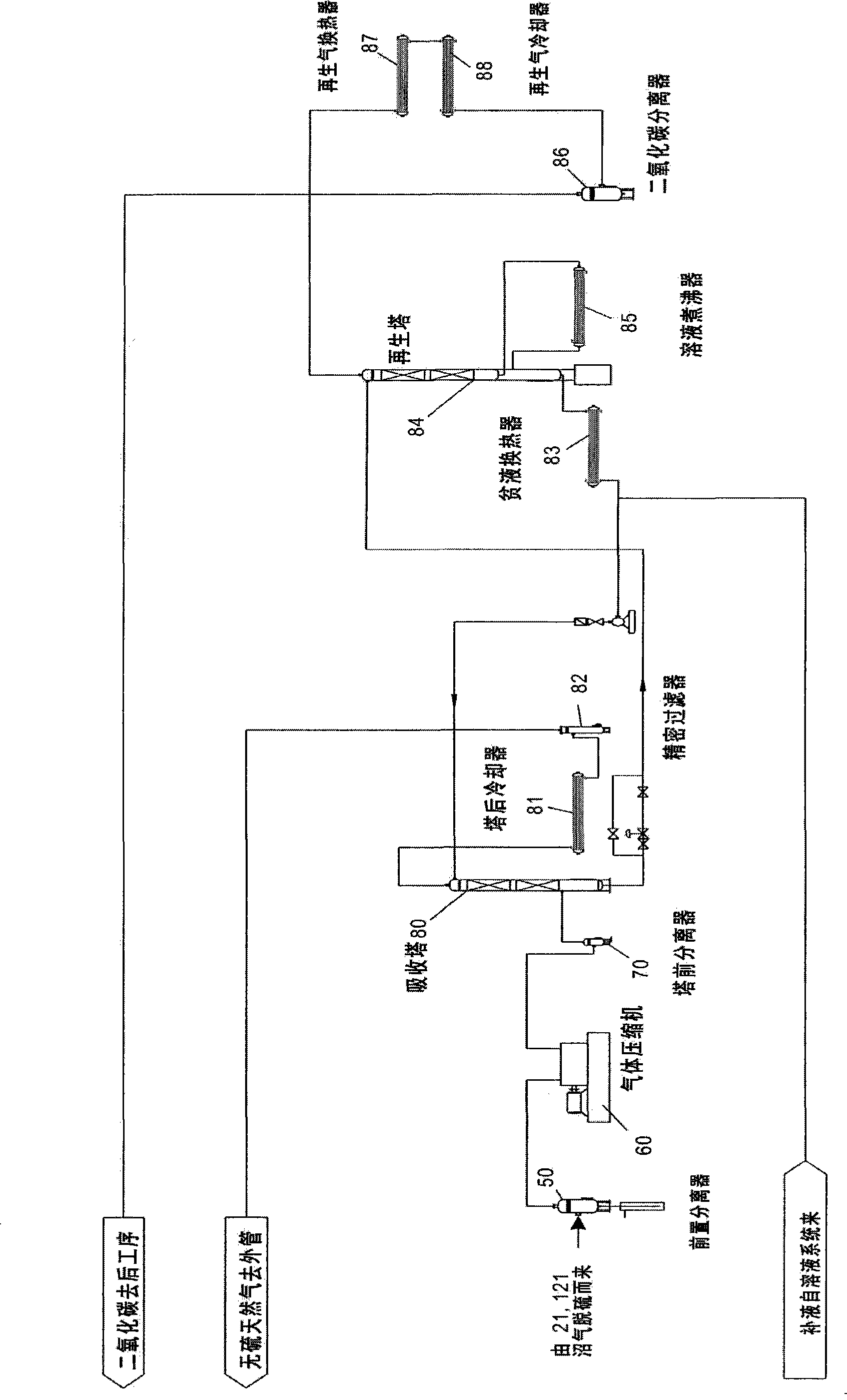

[0048] In order to further illustrate the principle and structure of the present invention, now in conjunction with Figure 1 ~ Figure 3 The preferred embodiments of the present invention are described in detail, but the embodiments are only for illustration and explanation, and cannot be used to limit the patent protection scope of the present invention.

[0049]A method for preparing sulfur-free natural gas from biogas, wherein the method for preparing sulfur-free natural gas from biogas comprises the steps of:

[0050] a. Removal of impurities. The removal of impurities is to input the prepared biogas into a solid-gas separation device through a control valve and control its pressure range between 0.5Mpa and 2Mpa, and remove the gas and dust and other raw material impurities in the biogas Phase separation, the biogas flow containing raw material impurities enters the separation device for solid-gas separation and gas-liquid separation, raw material impurities such as dust a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com