Method for assembling inelastic sealed ring and assembling device for implementing the method

An assembly method and technology of an assembly device, which are applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of non-elastic sealing ring without free elasticity and returnability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The assembly method of the non-elastic sealing ring of the present invention and the assembly device for implementing the method will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0032] A method for assembling a non-elastic sealing ring, the steps of which are as follows:

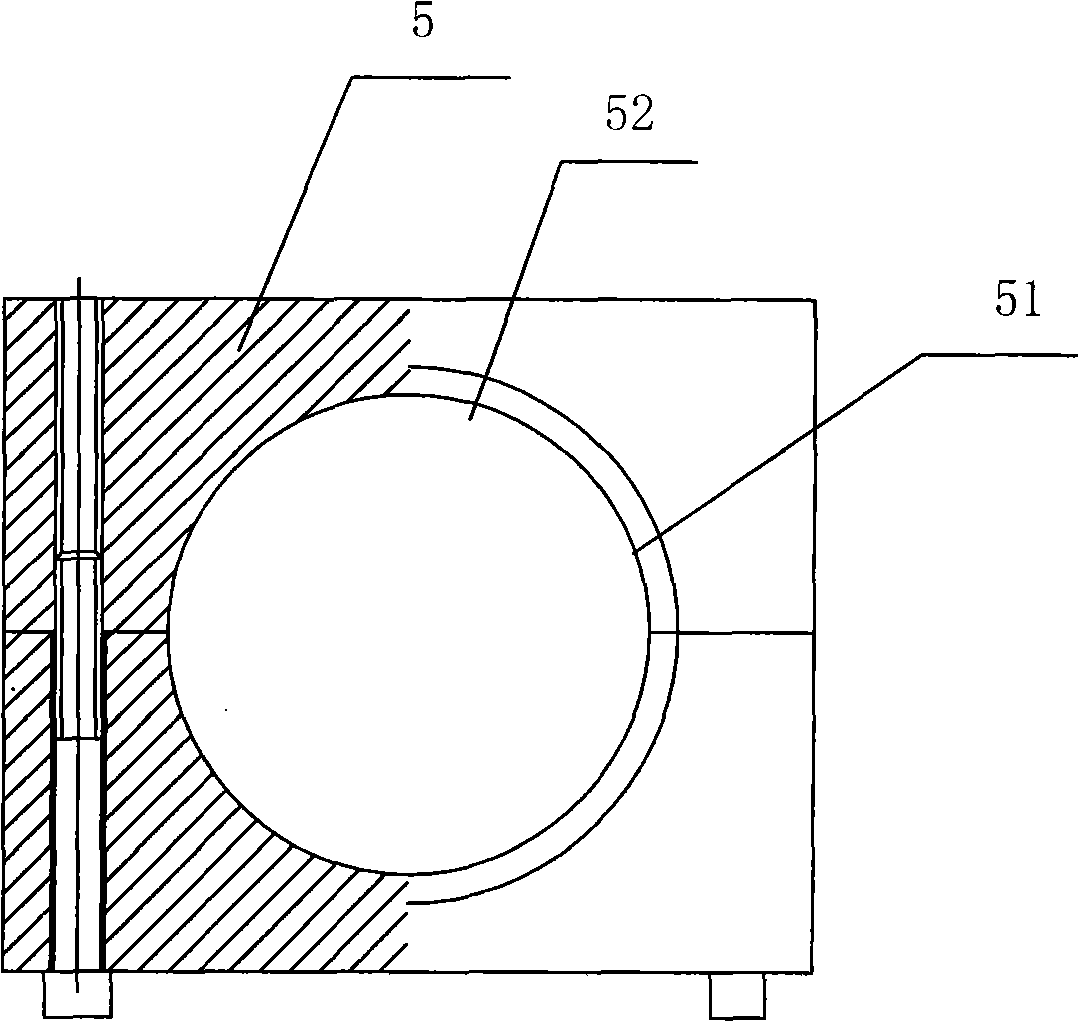

[0033] 1. First, fix the rotating shaft workpiece that needs to be assembled with the sealing ring on the workbench;

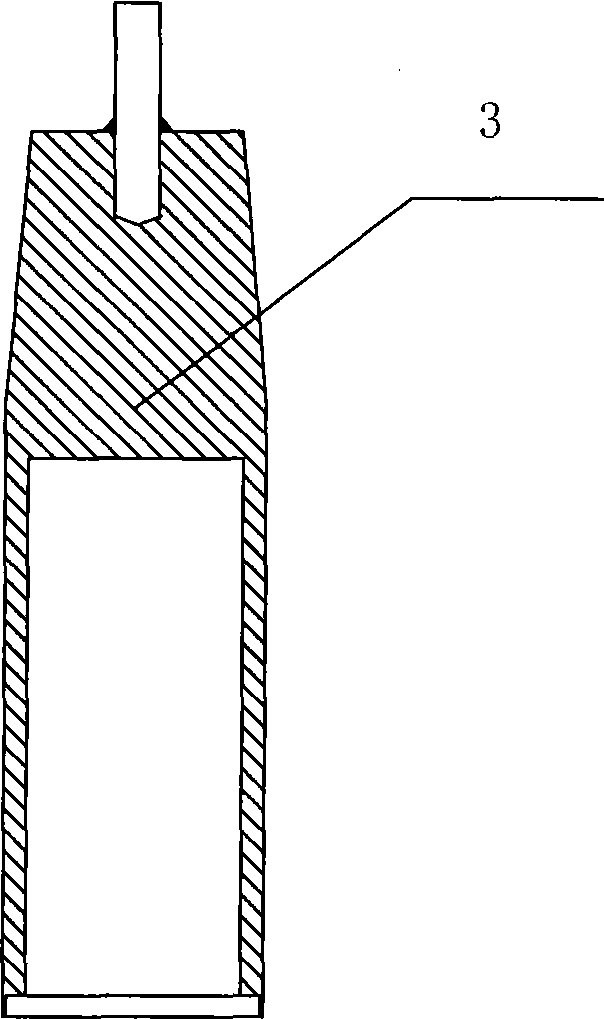

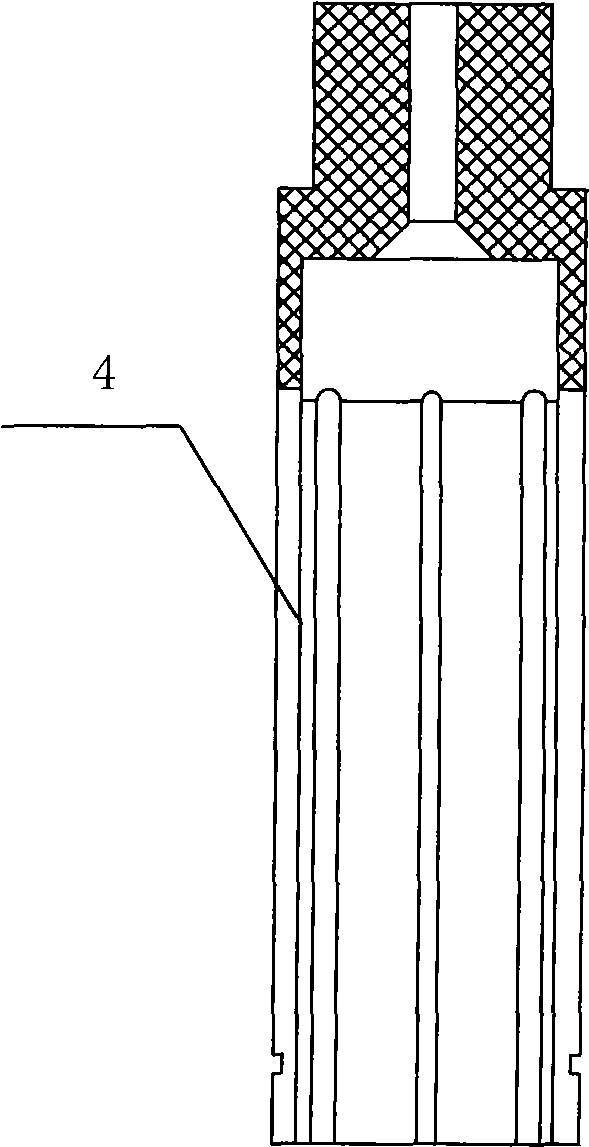

[0034] 2. Put a guide cylinder with a smooth outer wall and a small diameter at the upper end and a cylindrical lower end on the rotating shaft, so that the lower port of the guiding cylinder is aligned with the upper rib of the sealing groove on the rotating shaft; the lower port of the guiding cylinder is The outer diameter is consistent with the outer diameter of the upper rib of the sealing groove on the rotating shaft; the so-called basically the same means that the difference in diameter is about 1mm.

[0035] 3. Expand t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com