Measuring method for concentration of organic additive in plating solution

A technology of organic additives and measurement methods, applied in the direction of material electrochemical variables, etc., can solve the problems of complex process and time-consuming, and achieve the effect of small measurement deviation, low instrument accuracy and experimental operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

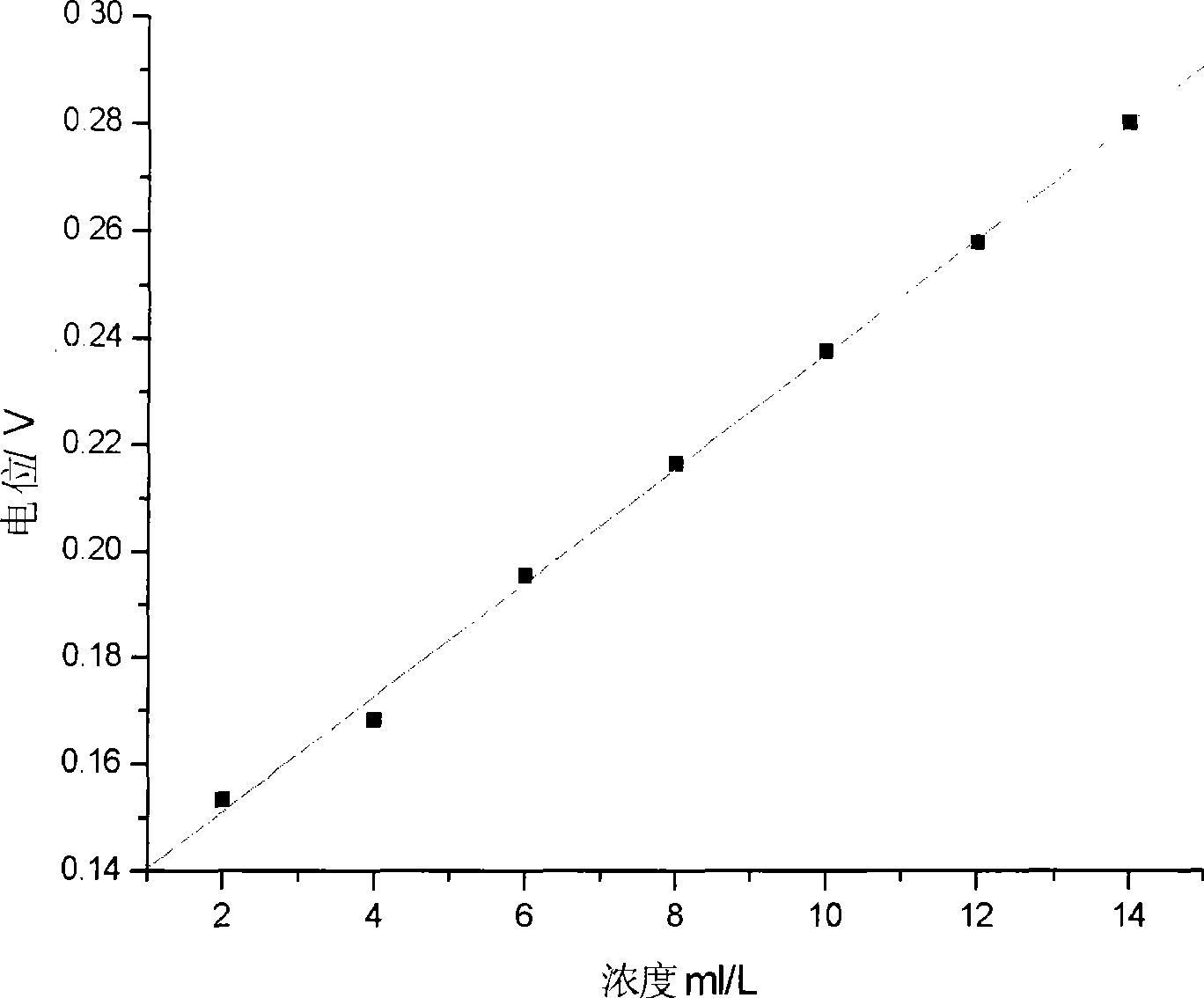

[0033] This embodiment illustrates the method for measuring the concentration of organic additives in the electroplating solution of the present invention.

[0034] (1) The electroplating solution to be tested is an aqueous solution, which contains 6.00ml / L inhibitor (19280 produced by Mai Demei), 70g / L CuSO 4 ·5H 2 O, 100g / L of H 2 SO 4 , 50ppm hydrochloric acid.

[0035] (2) Blank plating solution A is an aqueous solution containing 70g / L of CuSO 4 ·5H 2 O, 100g / L of H 2 SO 4 , 50ppm hydrochloric acid.

[0036] (3) In addition to the inhibitors containing 2ml / L, 4ml / L, 6ml / L, 8ml / L, 10ml / L, 12ml / L, and 14ml / L respectively, the other components and concentrations of the seven standard plating solutions A Both have the same composition as the blank plating solution A.

[0037] 2) Preparation method of porous mesh platinum electrode

[0038] Dip the titanium sheet in 1mol / L hydrochloric acid, react at 85°C for 10min, and clean the surface. Clean in water for 10min un...

Embodiment 2

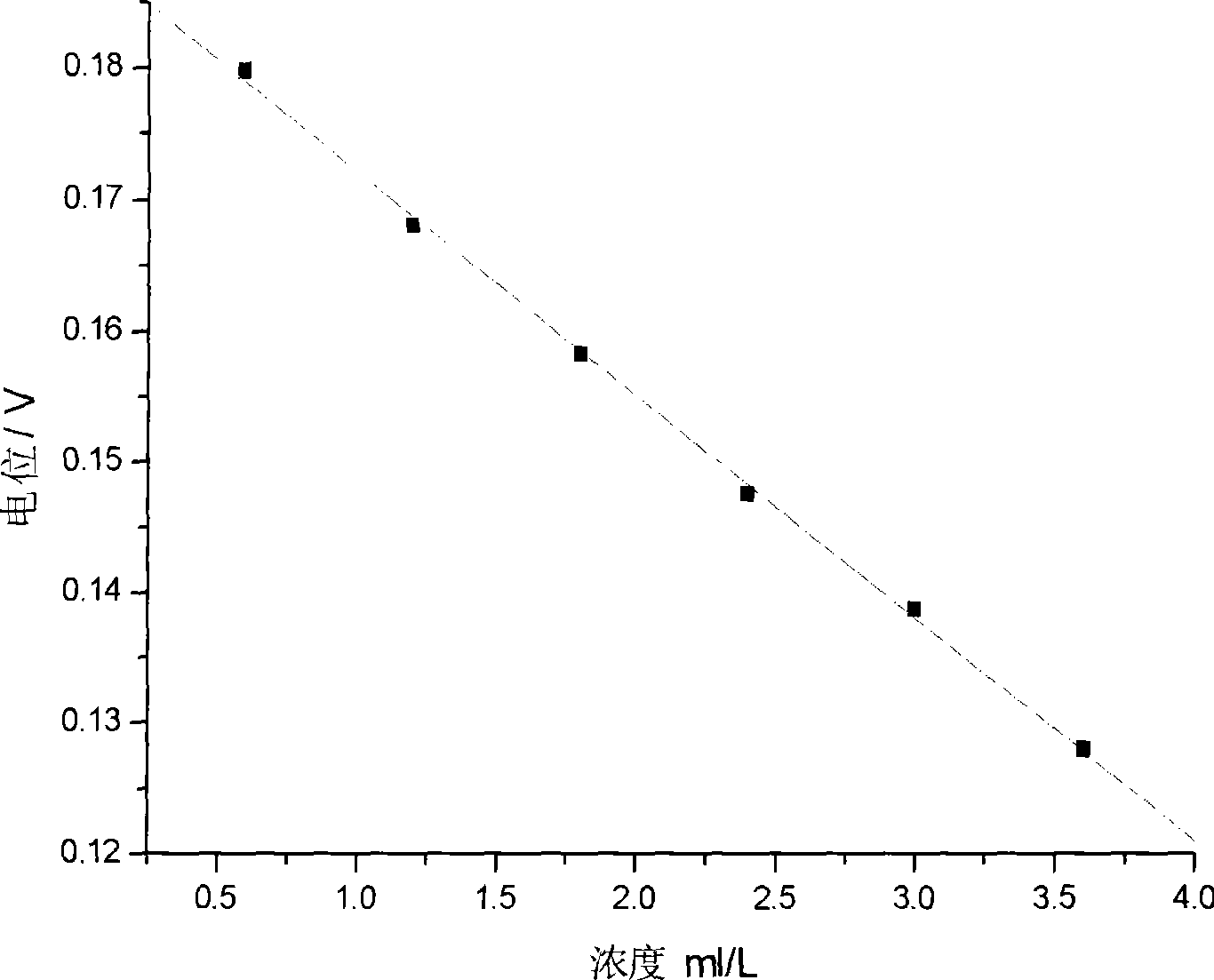

[0045] This embodiment illustrates the method for measuring the concentration of organic additives in the electroplating solution of the present invention.

[0046] (1) The electroplating solution to be tested is an aqueous solution, which contains 2.50ml / L brightener (19241 produced by Maidemi), 70g / L CuSO 4 ·5H 2 O, 100g / L of H 2 SO 4 , 50ppm hydrochloric acid.

[0047] (2) Blank plating solution A is an aqueous solution containing 70g / L of CuSO 4 ·5H 2 O, 100g / L of H 2 SO 4 , 50ppm hydrochloric acid.

[0048] (3) In addition to the brighteners containing 0.6ml / L, 1.2ml / L, 1.8ml / L, 2.4ml / L, 3.0ml / L, and 3.6ml / L respectively, other components of the six standard plating solutions B And its concentration is the same as the composition of blank plating solution A.

[0049] 2) Preparation method of porous mesh platinum electrode

[0050] Dip the titanium sheet in 1mol / L hydrochloric acid, react at 85°C for 10min, and clean the surface. Clean in water for 10min under u...

Embodiment 3

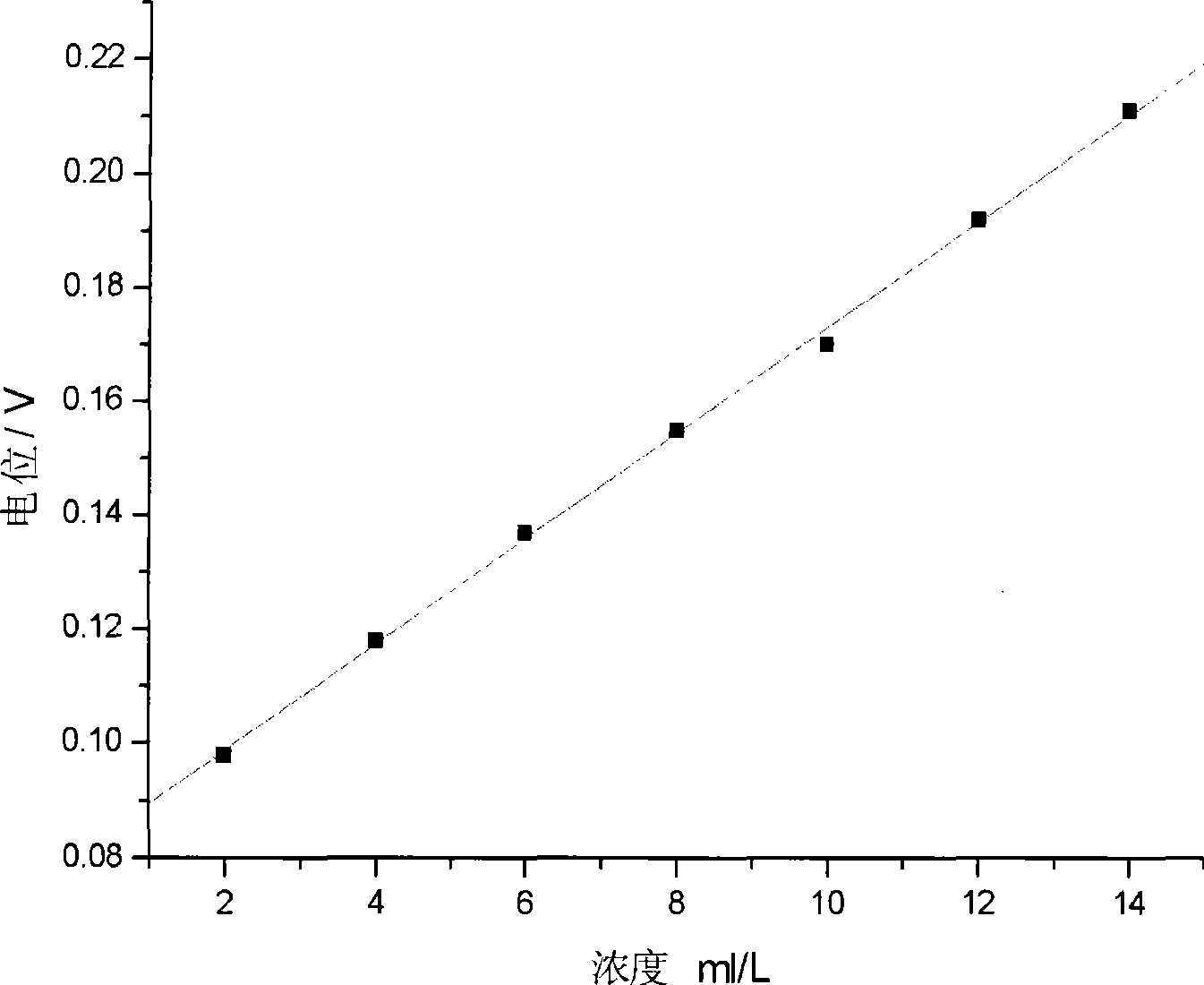

[0057] This embodiment illustrates the method for measuring the concentration of organic additives in the electroplating solution of the present invention.

[0058] 1) Reagents:

[0059] (1) The electroplating solution to be tested is an aqueous solution, which contains 6.00ml / L of inhibitor (19280 produced by Maidemi), 2.50ml / L of brightener (19241 produced by Maidemi), and 70g / L of CuSO 4 ·5H 2 O, 100g / L of H 2 SO 4 , 50ppm hydrochloric acid.

[0060] (2) Blank plating solution A is an aqueous solution containing 70g / L of CuSO 4 ·5H 2 O, 100g / L of H 2 SO 4 , 50ppm hydrochloric acid.

[0061](3) In addition to the inhibitors containing 2ml / L, 4ml / L, 6ml / L, 8ml / L, 10ml / L, 12ml / L, and 14ml / L respectively, the other components and concentrations of the seven standard plating solutions A Both have the same composition as the blank plating solution A.

[0062] (4) Blank plating solution B is an aqueous solution containing 35ml / L of inhibitors and 70g / L of CuSO 4 ·5H 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com