Method for improving working accuracy of PEEP valve

A high-precision, airway pressure technology, used in valves, respirators, etc., to solve problems such as a lot of system time and resources, high working accuracy, and cumbersome testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

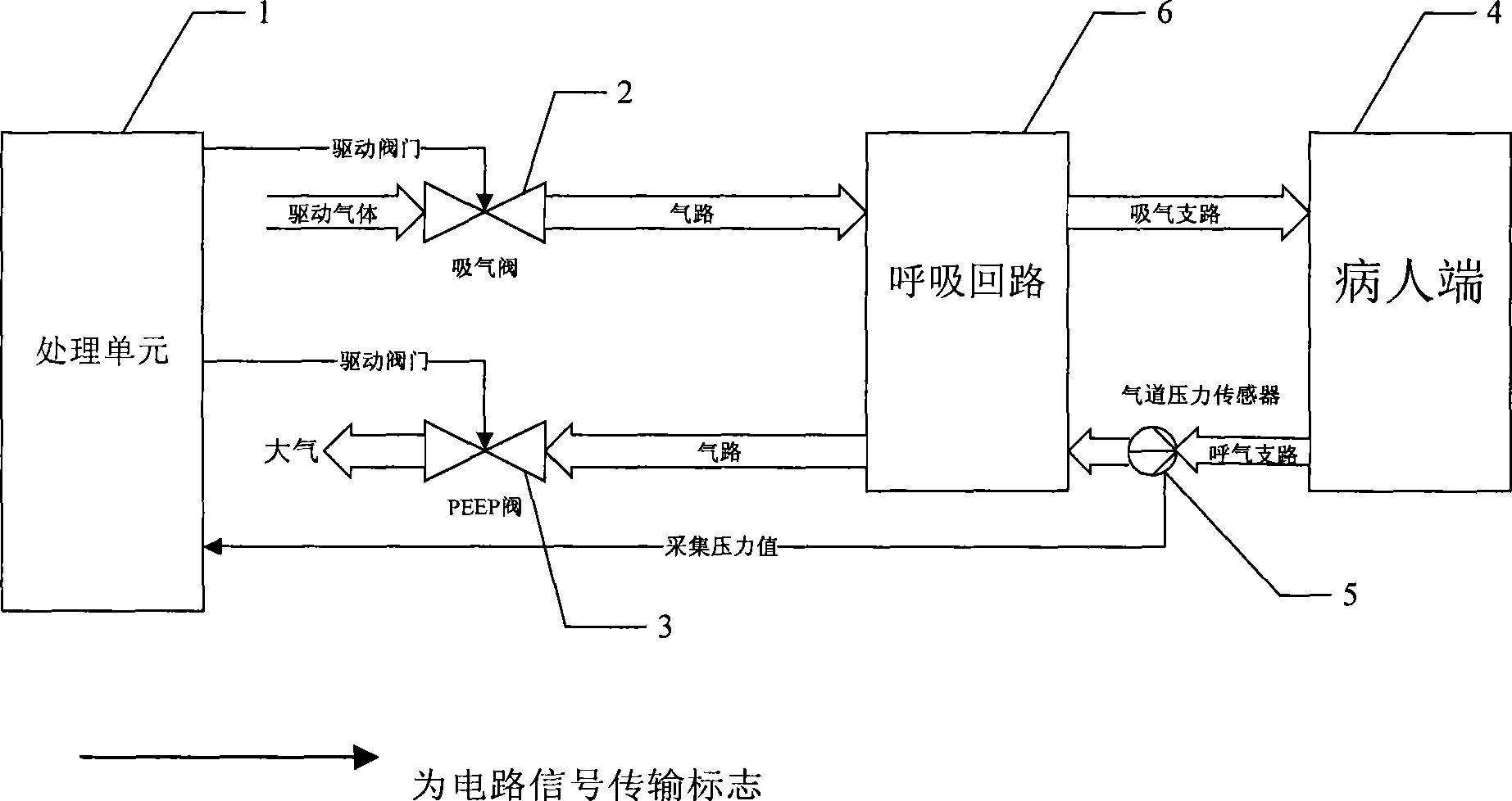

[0026] The specific real-time manner of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] The equipment used to realize the method of the present invention includes: a processing unit 1, an air circuit system, a data acquisition and receiving system, a PEEP valve and a drive unit controlled by a microprocessor of the processing unit 1; the air circuit system includes a breathing circuit 6, and Respectively connect the pipeline on the driver side of the breathing circuit and the breathing pipeline on the patient side 4 side; the breathing pipeline on the patient side includes an inhalation branch and an exhalation branch; an inhalation valve is connected to the pipeline on the driver side 2 and the PEEP valve 3 for external exhaust of the breathing circuit, the PEEP valve 3 is used to discharge the driving gas into the atmosphere; the sensor for collecting the pressure value at the end of the expiratory cycle includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com