Temperature-controlled explosion method for gasified deep part coal body of coal mine underground coal bed

A coal seam and deep technology, which is applied in the field of promoting the full combustion of deep coal in the working face of underground coal seam gasifiers, can solve the problems of small gasification reaction area, poor coal seam permeability, and low gasification gas production, so as to improve the resource recovery rate , low cost, and the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

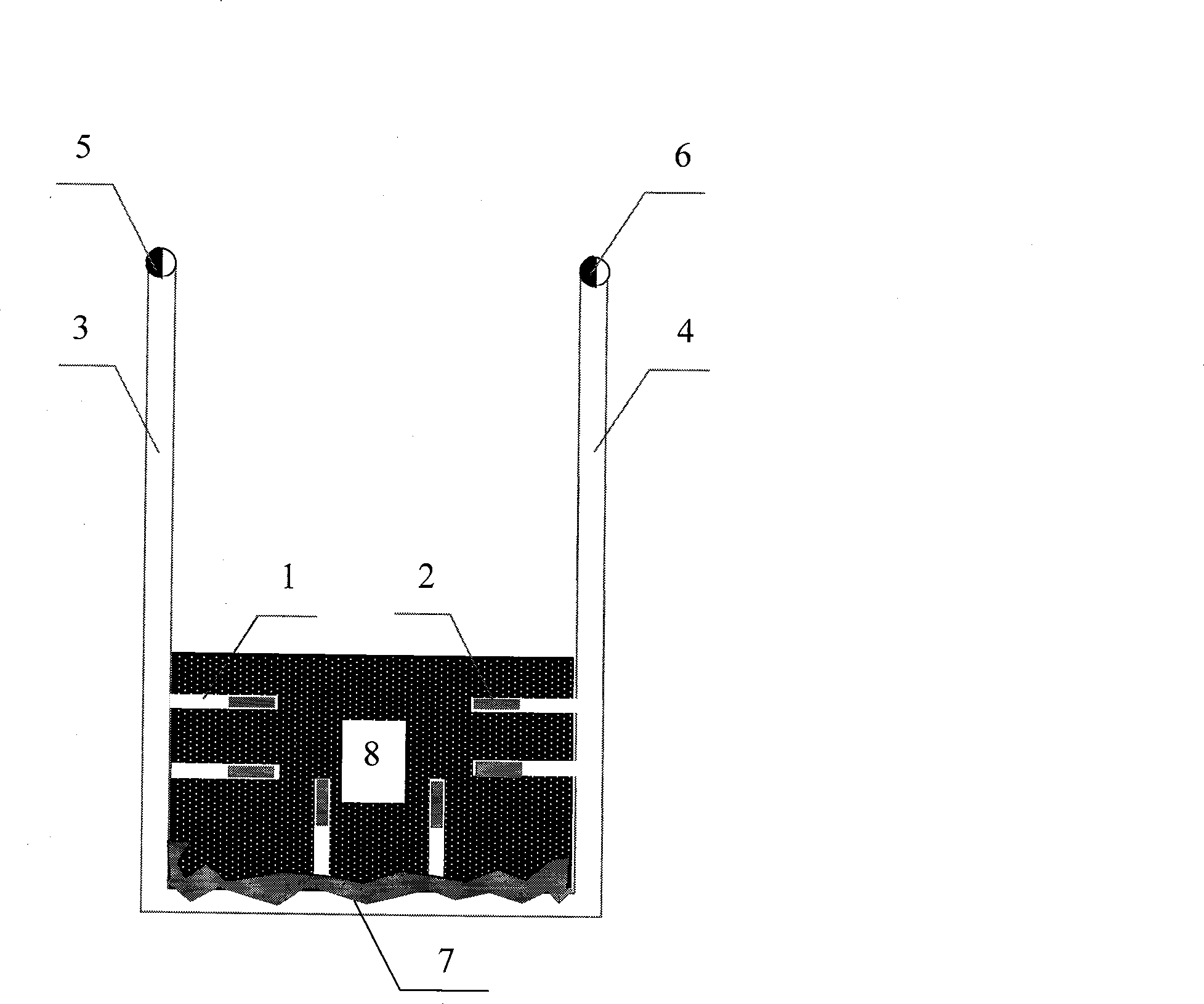

[0015] 1. Drill holes (1) into the coal seam (8) at a certain interval along the direction of the coal seam (8);

[0016] 2. Drilling (1) The optimum hole spacing is 5.0-20.0m; it can also be applied to a hole diameter of 3-20m. Empty holes (drilled holes without explosives) can also be arranged to increase the free surface;

[0017] 3. The optimal diameter of the drilling hole (1) is 38-42mm, and the diameter can also be between 25-200mm;

[0018] 4. Drilling (1) The optimum hole depth is 40.0-70.0m;

[0019] 5. Place temperature-controlled explosives (2) at the bottom of the borehole (1);

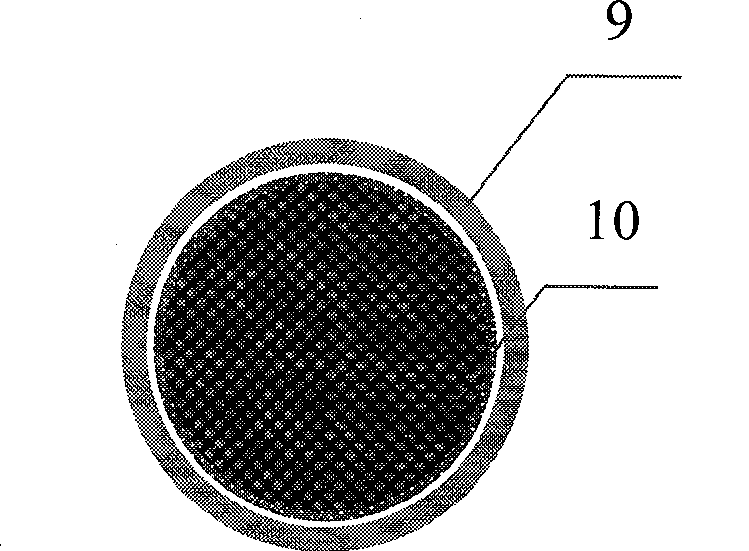

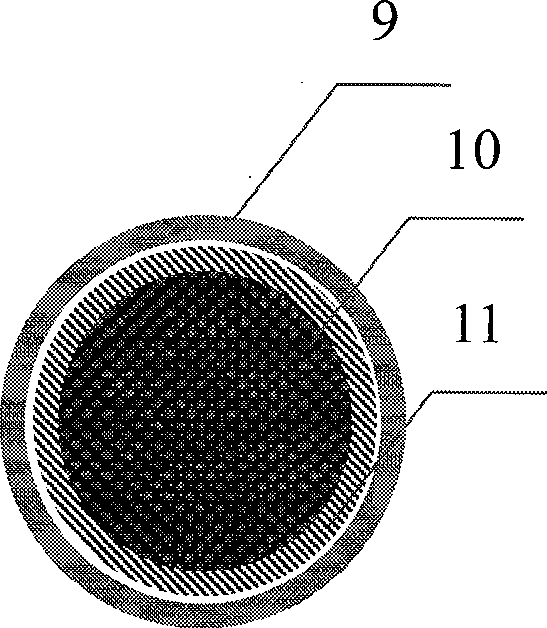

[0020] 6. The temperature-controlled explosive (2) is manufactured by making the explosive (10) explode at a temperature higher than a certain temperature, or wrapping the casing (11) outside the ordinary explosive (10), and the wrapping casing (11) is higher than a certain temperature. The explosive (10) explodes at a certain temperature. During the combustion process of the coal seam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com