Wine vat apparatus of beer filling capping machine

A technology of capping machine and wine tank, which is applied in liquid filling and other directions, can solve problems such as waste of resources, spillage of wine liquid, easy fouling, etc., and achieve the effects of maintaining consistency, convenient cleaning and stable filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

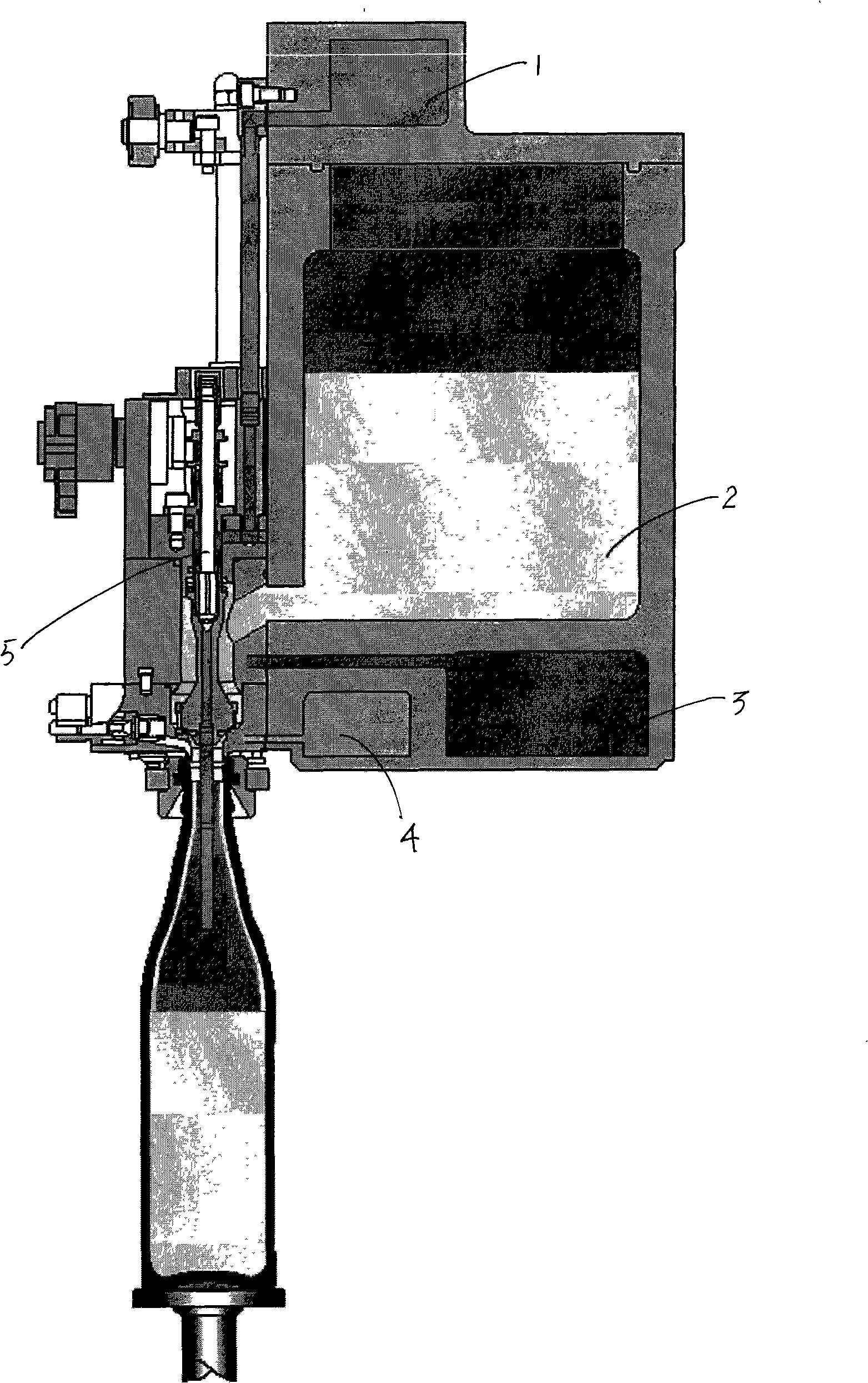

[0010] Depend on figure 1 As shown, a wine tank device of a beer filling and capping machine of the present invention includes a wine chamber 2 and a vacuum chamber 3; it is characterized in that a return air chamber 1 and a pressure relief chamber 4 are also provided in the wine tank, so that Said air return chamber 1 is located on the upper part of the wine tank, isolated from the wine chamber 2, and the air return chamber 1 is connected with the air return passage of the beer filling valve 5 of the beer filling and capping machine; the said pressure relief chamber 4 It is located at the bottom of the wine vat and is connected with the filling port of the beer filling valve 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com