Improved book-binding machine handpiece

A technology of binding machine and machine head, which is applied in the direction of binding, etc., to achieve the effect of low cost, guaranteed binding quality and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

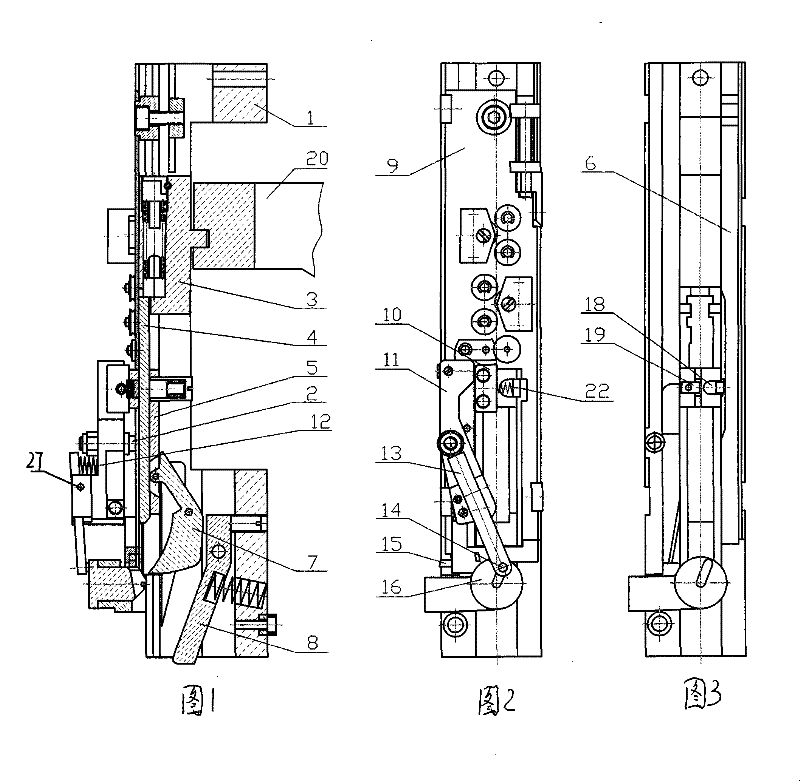

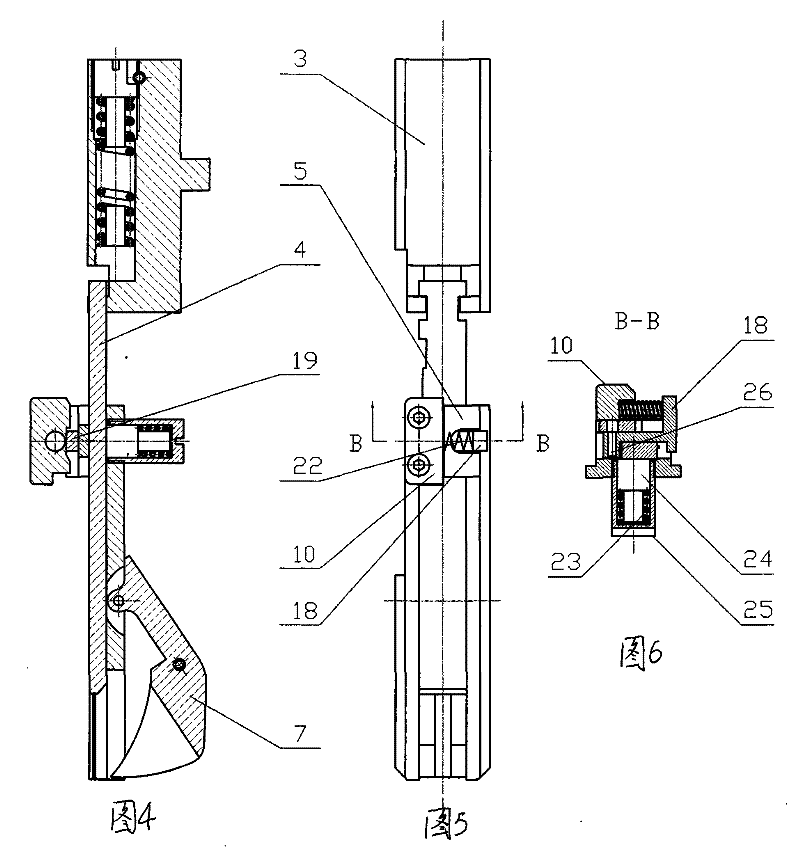

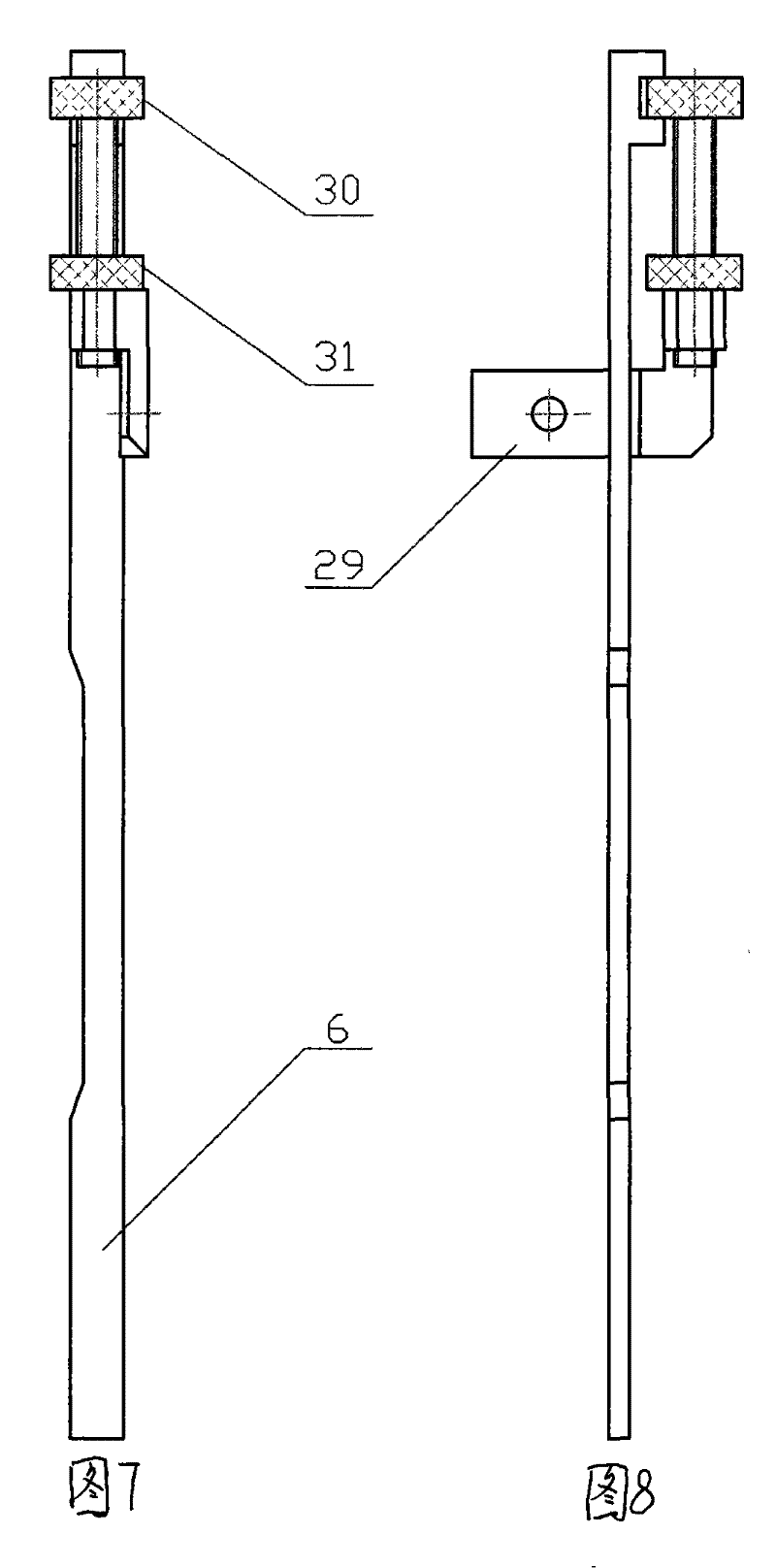

[0016] As shown in Figure 1-6, an improved binding machine head, including the head shell, consists of a hook slide plate, a staple slide block, a hook slide plate, a tongue-shaped hook, a collision block, a toothed plate, a pressure spring and The hook slide plate component composed of transmission bumper, the machine head cover plate component composed of machine head cover plate, eccentric shaft, straightening mechanism, steel wire spring, pressure plate and cutter frame, and the forming column composed of bracket and forming column Parts, and the control bar parts composed of control bar, adjusting seat, adjusting screw and lock nut. The hook slide plate 5 is movably installed in the guide groove of the machine head housing 1, the middle part of the hook slide plate 4 is placed in the guide groove of the hook slide plate, and the upper part is hung on the groove of the staple slide block 3, and the staple slide block and the eccentric The binding hand 20 at the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com