Ink cartridge for ink jet printer

A technology of inkjet printers and printers, which is applied in printing and other fields, and can solve problems such as the influence of ink remaining amount and the inability to independently detect the installation of ink cartridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

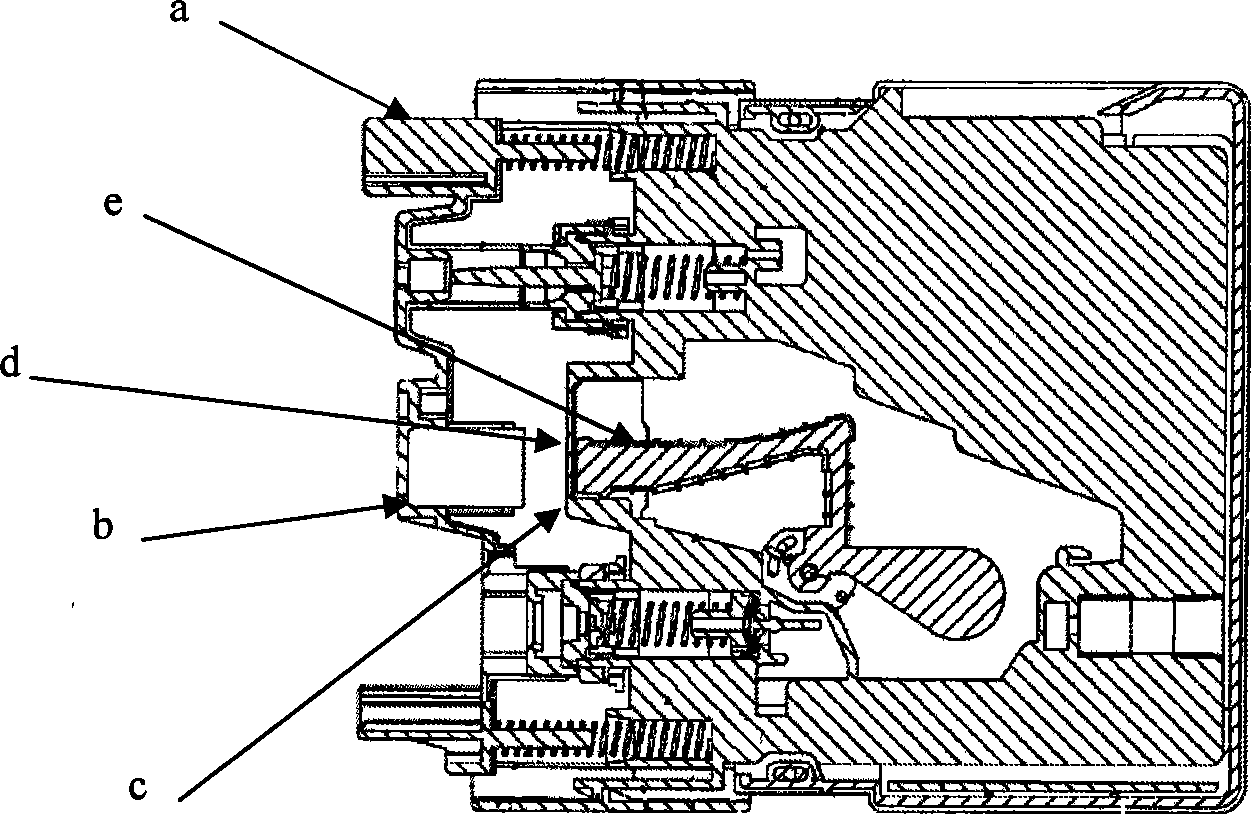

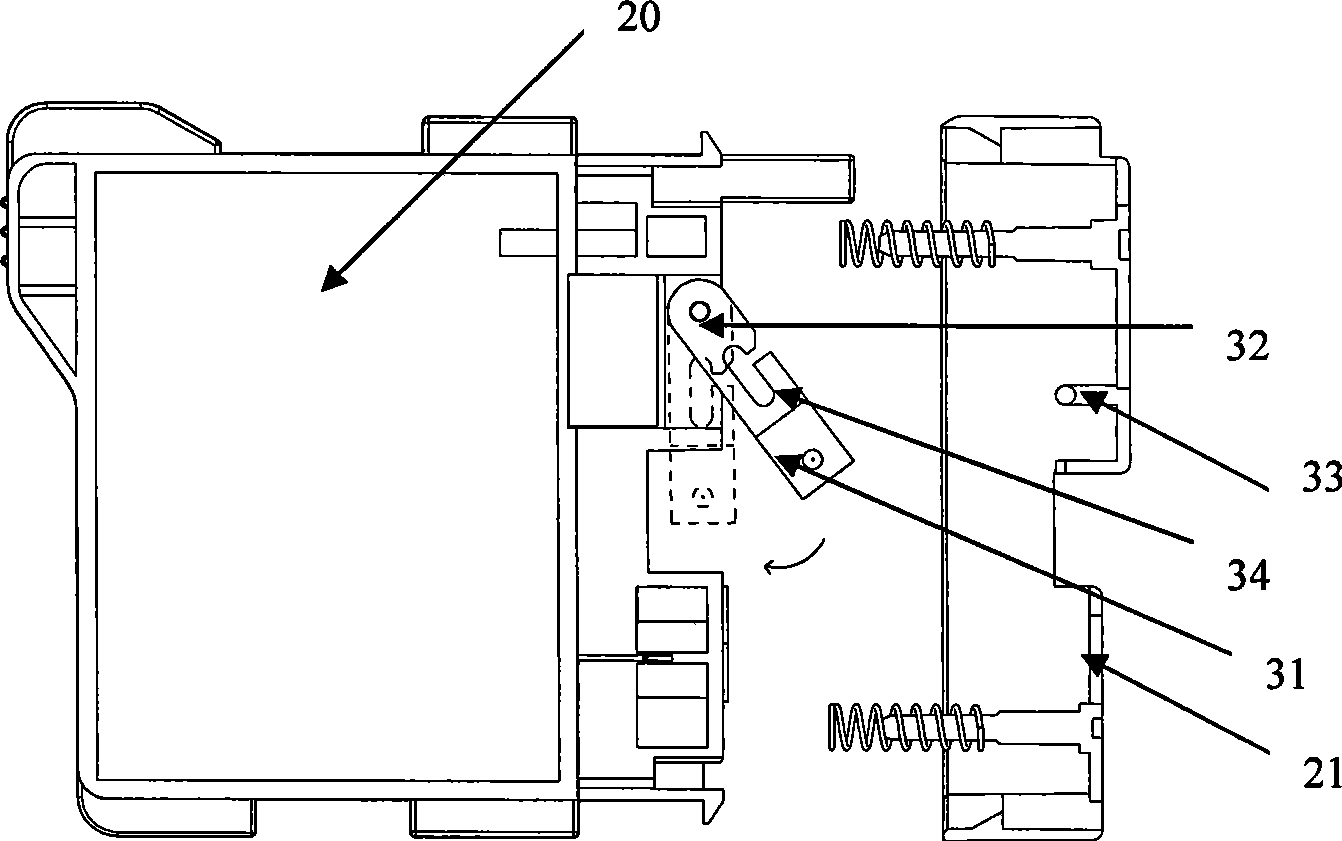

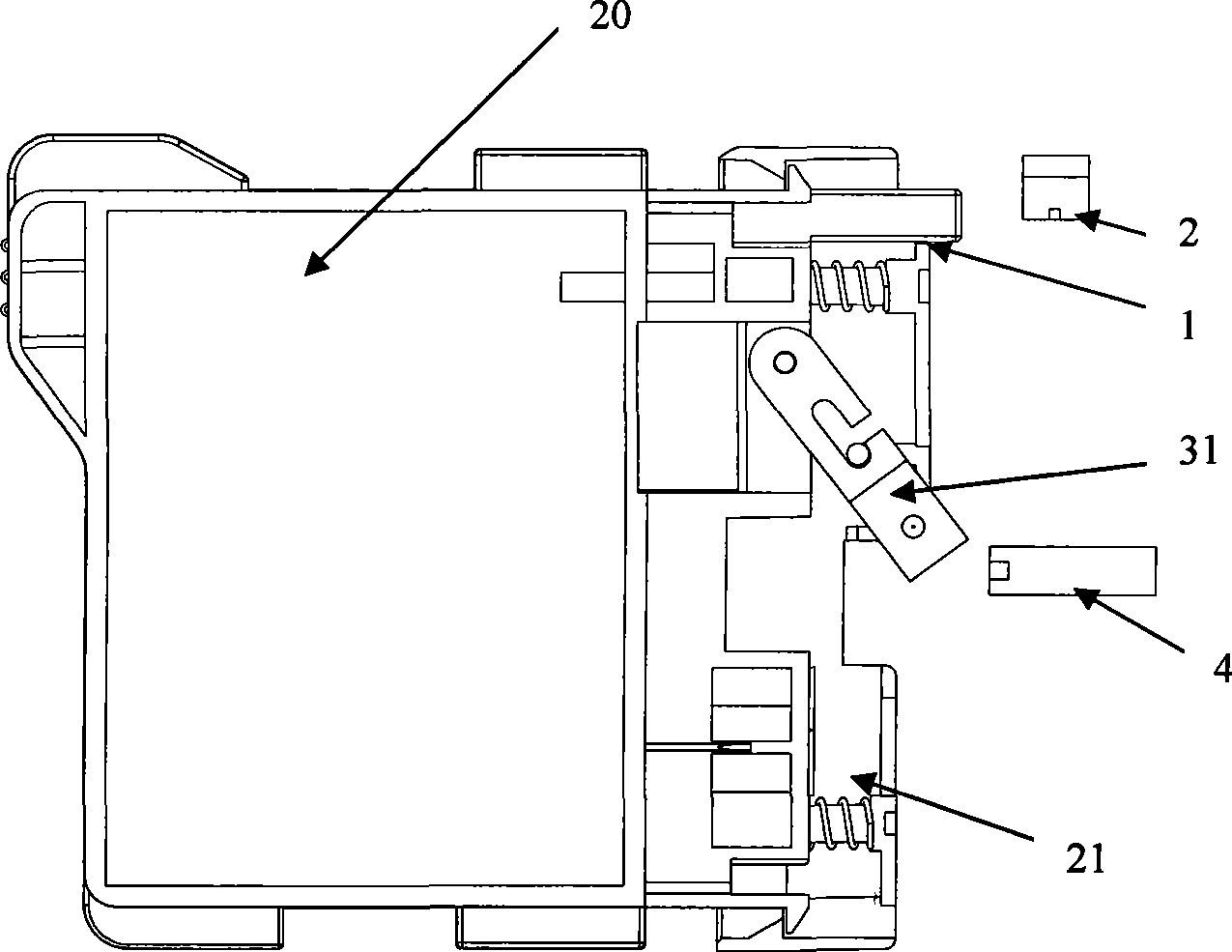

[0031] Such as figure 2 As shown, an ink cartridge for an inkjet printer includes a cartridge body 20, a protective cover 21 that can move relative to the cartridge body under pressure, an ink cartridge detection mechanism for detecting the ink cartridge, and ink for detecting the remaining amount of ink Remaining amount detection mechanism, the box body 21 includes an ink storage chamber 5 for storing ink, an ink outlet for supplying ink to the print head of the printer, and an air inlet. The ink cartridge detection mechanism includes a first detection sensor that matches the first sensor 2 on the printer. Component 1 and the second detection component matched with the second sensor 4 on the printer, the second detection component includes a shielding part 31, a fixed shaft 32 set on the box body 20, a movable shaft 33 set on the protective cover 21 and the position recovery of the shielding part The blocking part 31 is connected with the fixed shaft 32, rotates around the f...

specific Embodiment 2

[0032] Such as Figure 9 As shown, an ink cartridge for an inkjet printer includes a cartridge body 20, a protective cover 21 that can move relative to the cartridge body under pressure, an ink cartridge detection mechanism for detecting the ink cartridge, and ink for detecting the remaining amount of ink Remaining quantity detection mechanism, box body 21 comprises the ink storage chamber 5 for storing ink, the ink outlet that supplies ink to the printing head of printer, air inlet, and the ink cartridge detection mechanism is the same as in embodiment one, and the ink remaining quantity detection mechanism comprises The trigger switch 7 arranged on the bottom of the ink storage chamber 5 and the luminous lamp 6 connected in series with the trigger switch 7, the luminous lamp 6 is arranged on the side of the shielding part 31 close to the second sensor receiving part and is electrically connected to the power supply, the trigger switch 7 is in the ink It is off when the ink i...

specific Embodiment 3

[0033] Such as Figure 12 As shown, an ink cartridge for an inkjet printer includes a cartridge body 20, a protective cover 21 that can move relative to the cartridge body under pressure, an ink cartridge detection mechanism for detecting the ink cartridge, and ink for detecting the remaining amount of ink Remaining quantity detection mechanism, box body 21 comprises the ink storage chamber 5 for storing ink, the ink outlet that supplies ink to the printing head of printer, air inlet, and the ink cartridge detection mechanism is the same as in embodiment one, and the ink remaining quantity detection mechanism comprises Be arranged on the trigger switch 7 at the bottom of the ink storage chamber and the luminous lamp 6 connected in series with the trigger switch 7. The luminous lamp 6 is arranged on the exposed position after the ink cartridge is installed and is electrically connected with the power supply. The trigger switch 7 is when the ink is not used up. Disconnected stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com