A coil connection structure of a transformer

A transformer and high-voltage coil technology, applied in the field of transformers, can solve problems such as tight insulation distance and complex wiring structure, and achieve the effect of increasing insulation distance, simplifying wiring structure, and meeting the requirements of insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

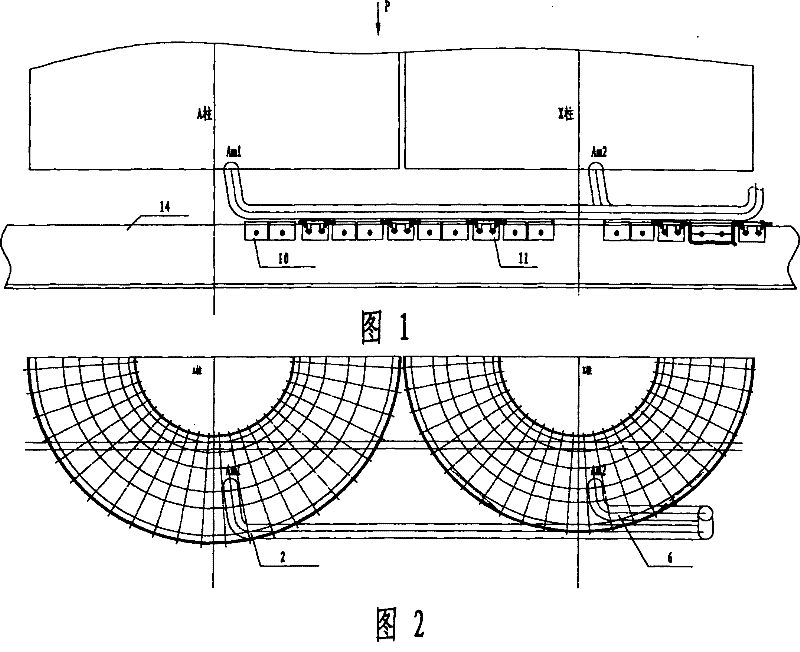

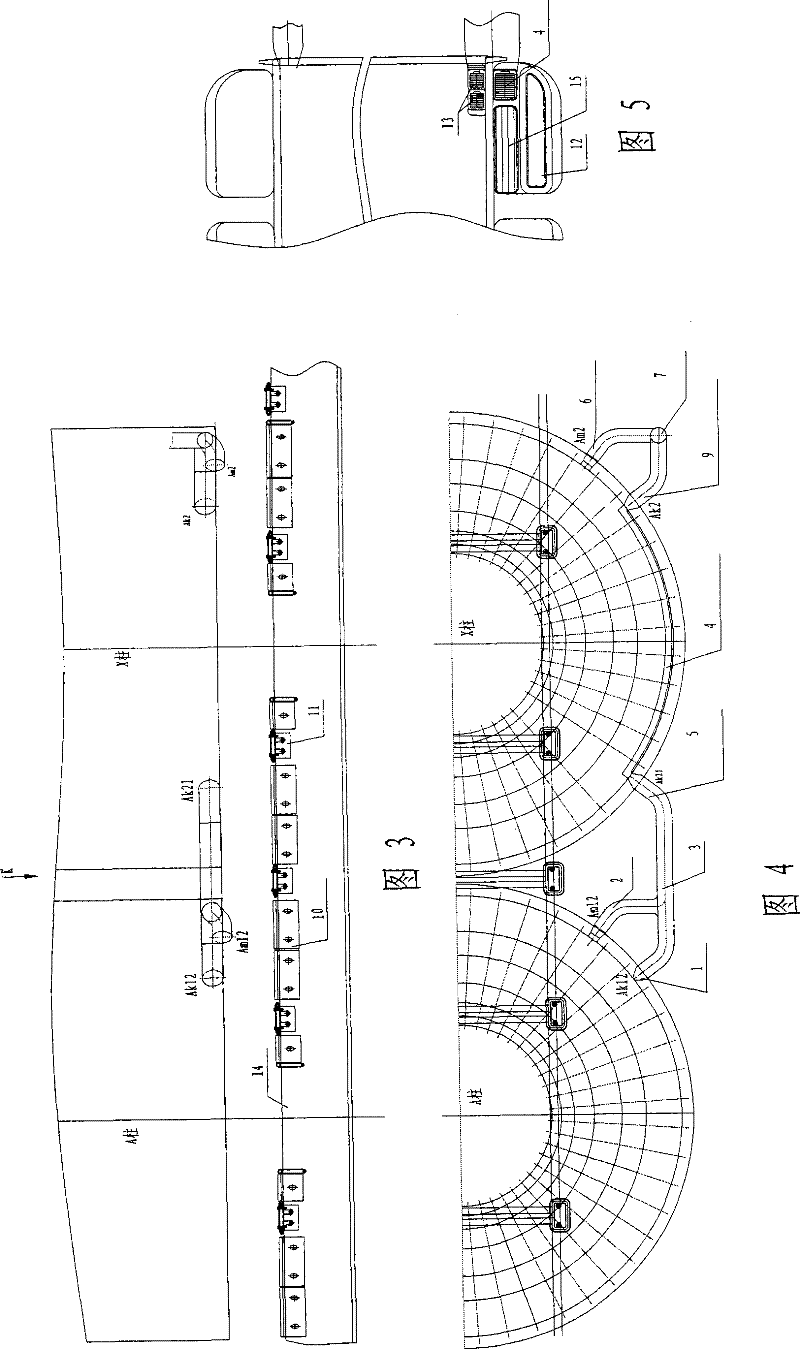

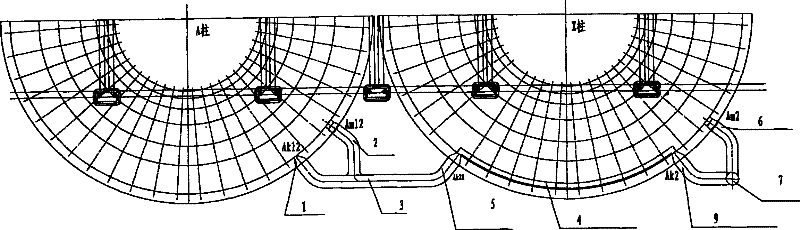

[0018] Such as image 3 , 4 As shown, the coil connection structure of the transformer of the present invention includes an A-column coil and an X-column coil, and both the A-column coil and the X-column coil include a high-voltage coil and a medium-voltage coil. According to the structural characteristics that the end of the high-voltage coil and the head end of the medium-voltage coil are equipotential, the end 1 of the high-voltage coil of the A-pillar is connected with the head 2 of the head-end of the medium-voltage coil of the A-pillar to form a first connection 3 . On the high-voltage coil electrostatic plate 12 of the X column, there is a notch along the circumferential direction, and a connecting wire 4 is placed at the notch. The connecting line 3 is connected, and the other end thereof is connected with the end of the high-voltage coil of the X column to form an intermediate connecting line 9, and the intermediate connecting line 9 is connected with the leading end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com