Coil connecting line construction for transformer

A technology for transformers and high-voltage coils, applied in the field of transformers, can solve problems such as tight insulation distances and complex wiring structures, and achieve the effects of increasing insulation distances, simplifying wiring structures, and solving wiring difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

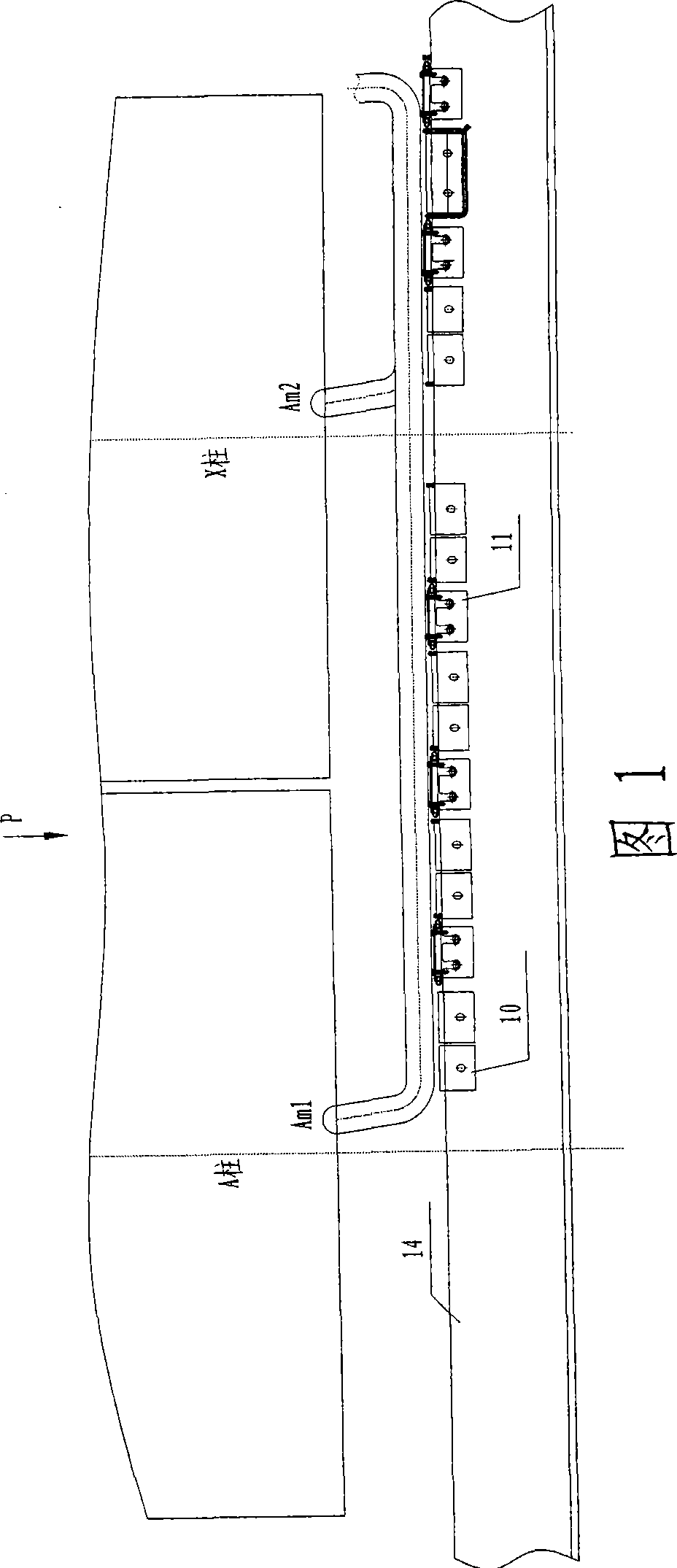

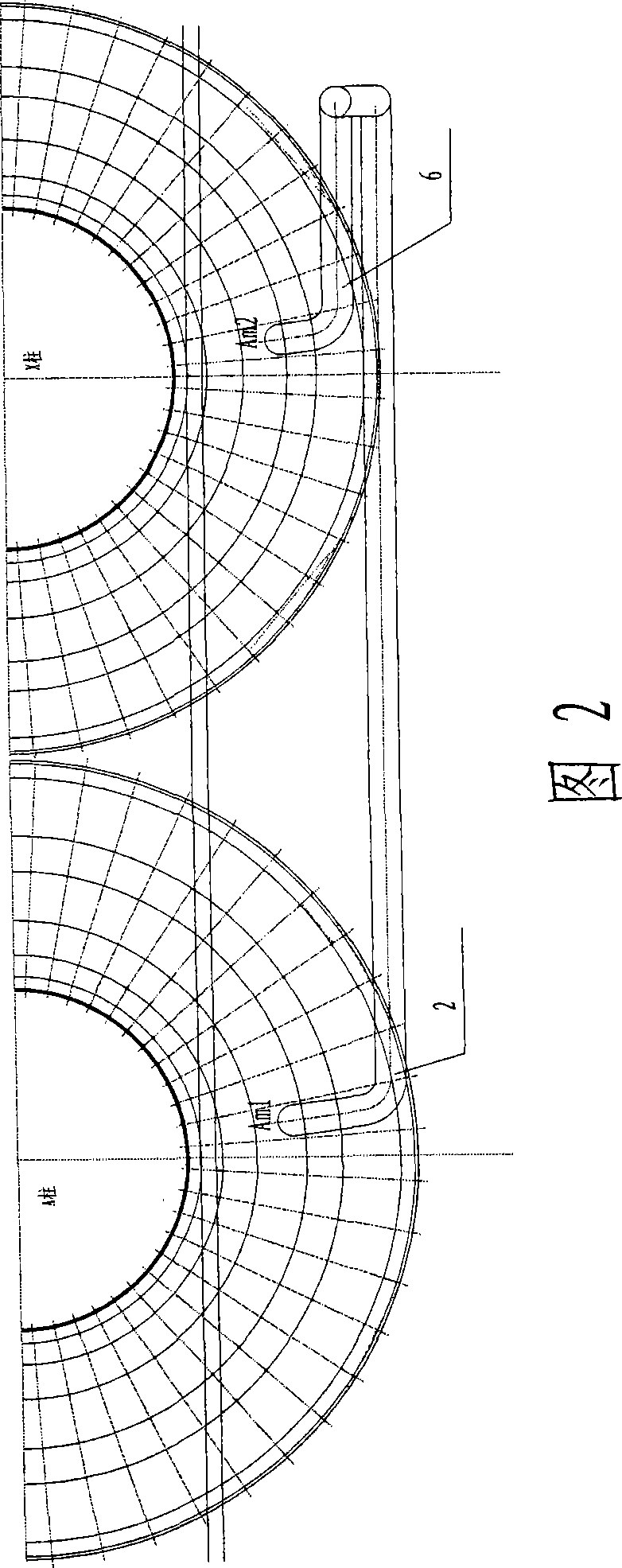

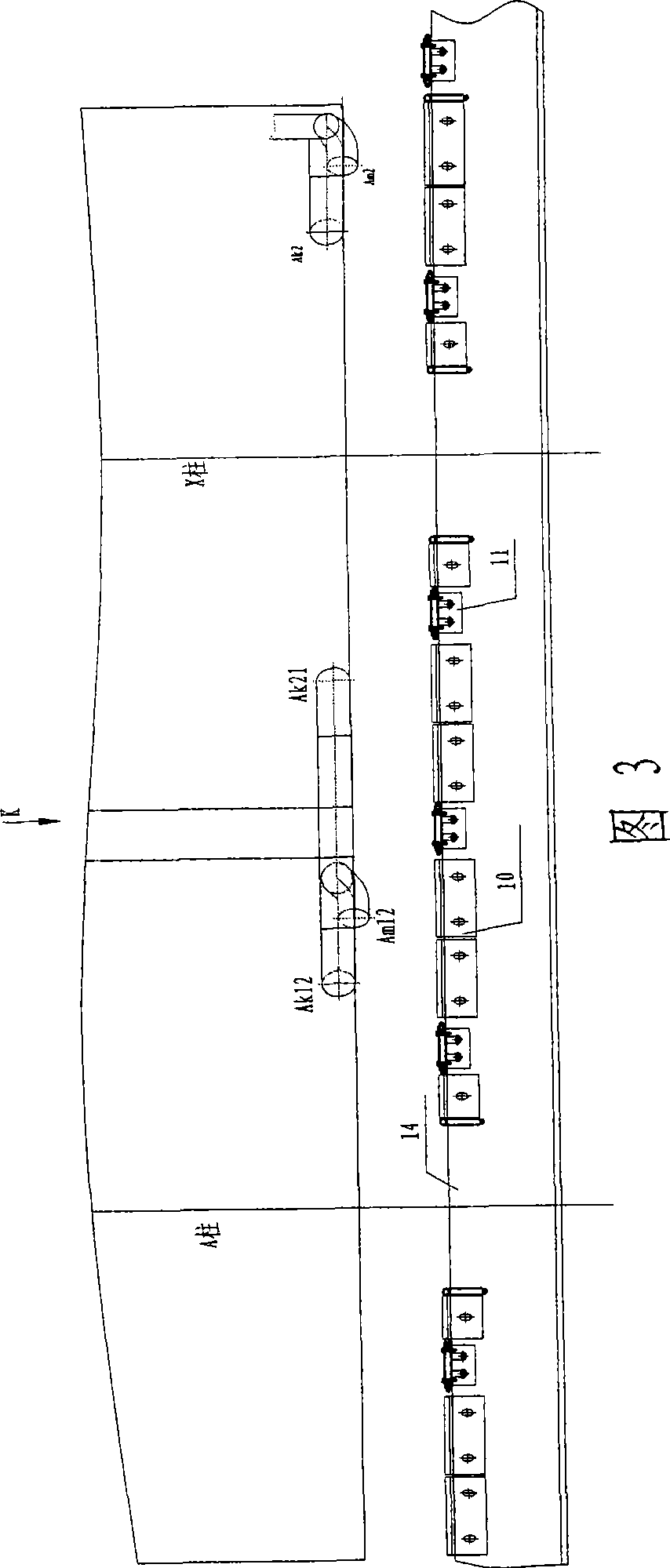

[0018] As shown in Figures 3 and 4, the coil connection structure of the transformer of the present invention includes an A-pillar coil and an X-pillar coil. Both the A-pillar coil and the X-pillar coil include a high-voltage coil and a medium-voltage coil. According to the structural characteristics of the equal potential between the end of the high voltage coil and the head end of the medium voltage coil, the high voltage coil end outlet 1 of the A-pillar and the medium voltage coil head end 2 of the A-pillar are connected to form a first connection line 3. The high-voltage coil electrostatic plate 12 of the X-pillar is provided with a notch along the circumferential direction, and a connecting wire 4 is placed at the notch. The connecting wire 4 passes through the electrostatic plate 12 in the radial direction of the electrostatic plate, and connects the wire outlet 5 and the first Connection 3 is connected, the other end of which is connected with the end of the high voltage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com