Current acquisition method at low speed segment of permanent magnet synchronous machine of compressor

A permanent magnet synchronous motor and acquisition method technology, which is applied in the direction of using digital measurement technology for measurement, can solve the problem of low current acquisition accuracy in low-speed sections, and achieve the effects of improving sampling resolution, reducing acquisition errors, and improving sampling accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

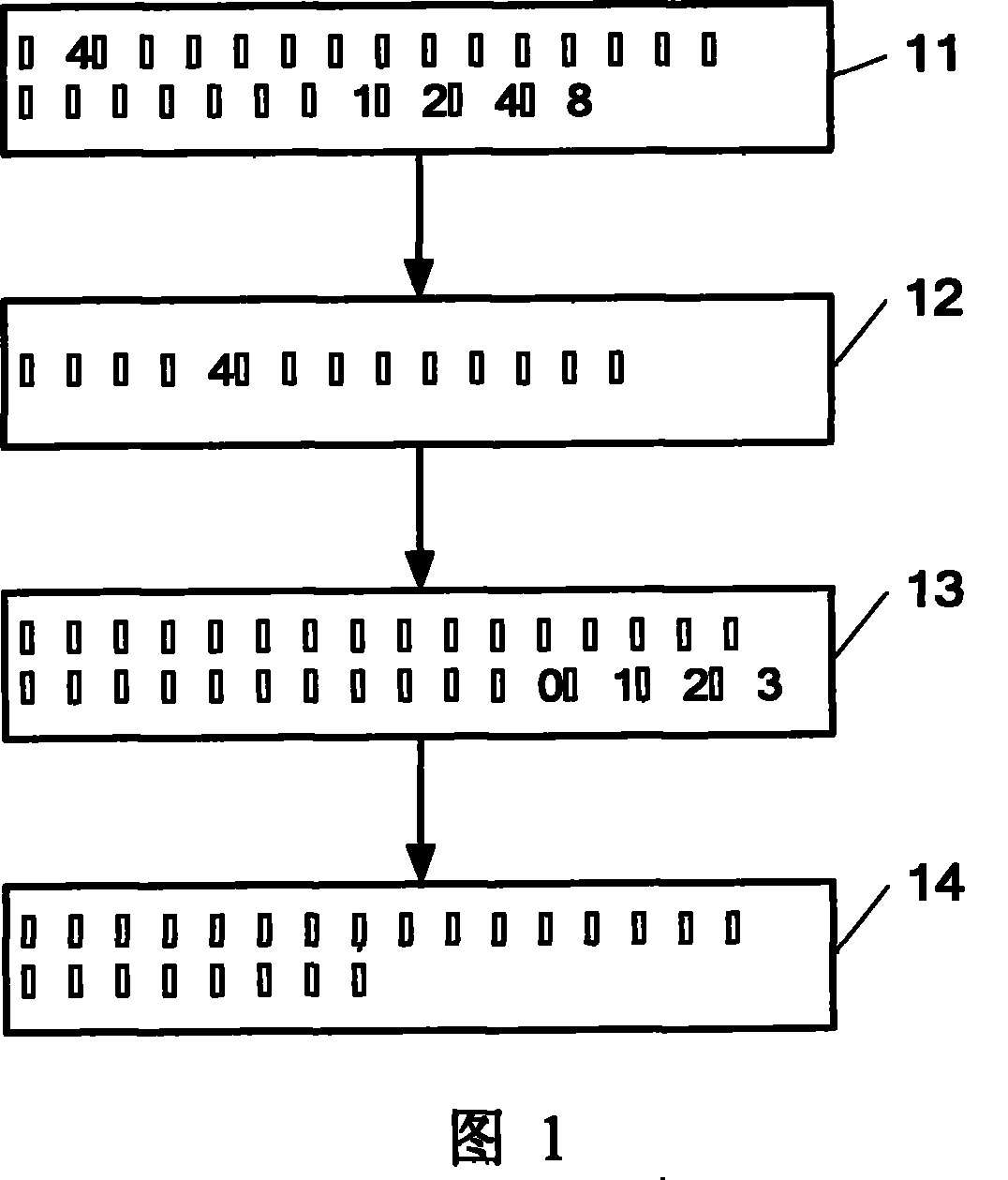

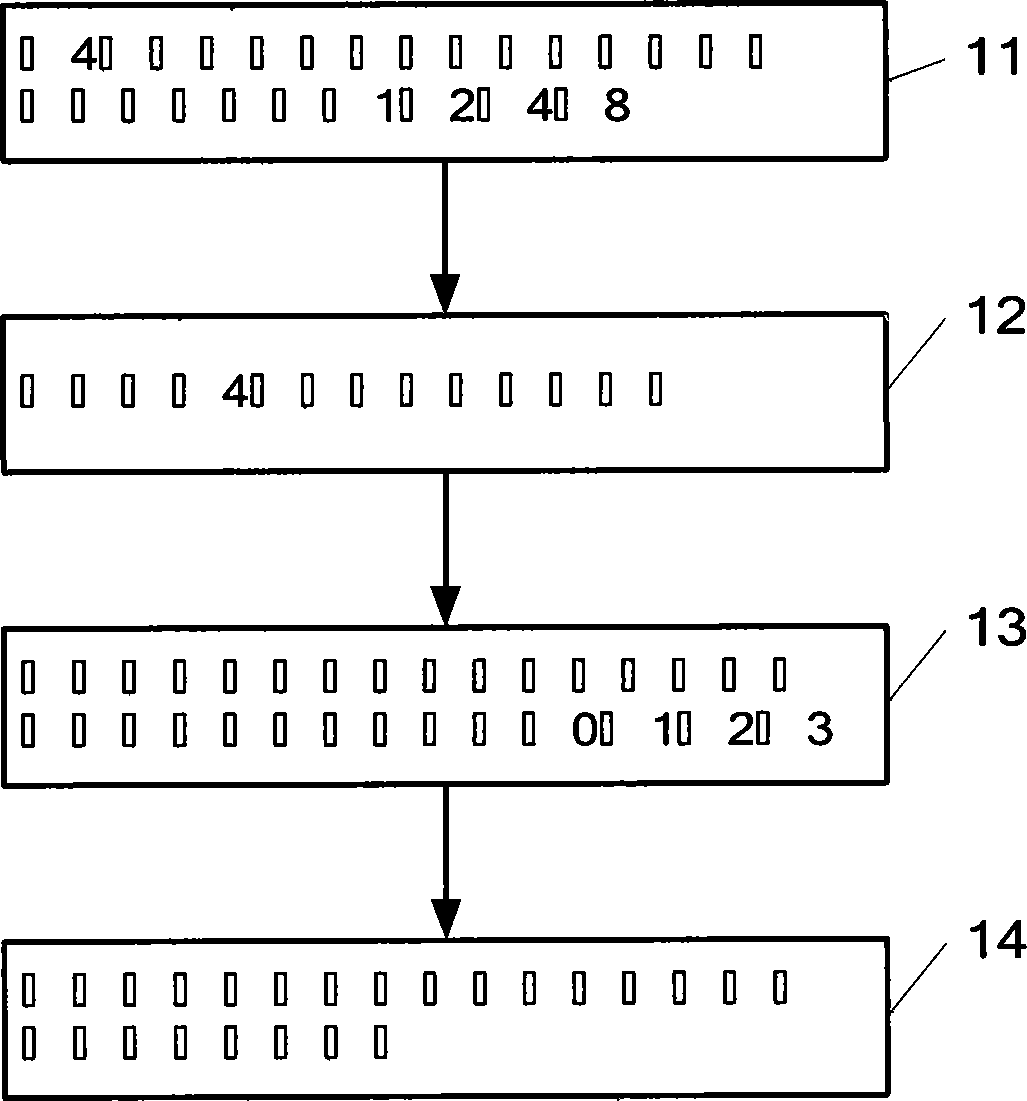

[0019] refer to figure 1 , a current acquisition method for the low-speed section of a permanent magnet synchronous motor of a compressor, the steps of which are as follows:

[0020] 1) Use 4-way amplifier TLC2464 to amplify the current signal. The magnifications are 1, 2, 4, 8 in turn. The input terminals of the four operational amplifiers are connected in parallel, and the current signal I is connected. After the 4 channels of current signals are amplified, they are output once as 1×I, 2×I, 4×I, 8×I, see process 11.

[0021] 2) Collect the amplified current signals 1*I, 2*I, 4*I, 8*I of the 4-way amplifiers respectively with the 4-way A / D on-chip of DSP. The values D1, D2, D4, and D8 of the four collected signals are obtained, see process 12.

[0022] 3) According to the magnification, the values of the collected signals of each channel are shifted to the right, and fixed-point number division is performed. The number of right shifts is 0 times for D1, 1 time for D2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com