Bridge erection method

A technology for bridges and beam sections, which is applied in the field of bridge erection in narrow construction sites, can solve the problems of narrow and uneven construction sites, inconvenient transportation, and inability to use large lifting equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

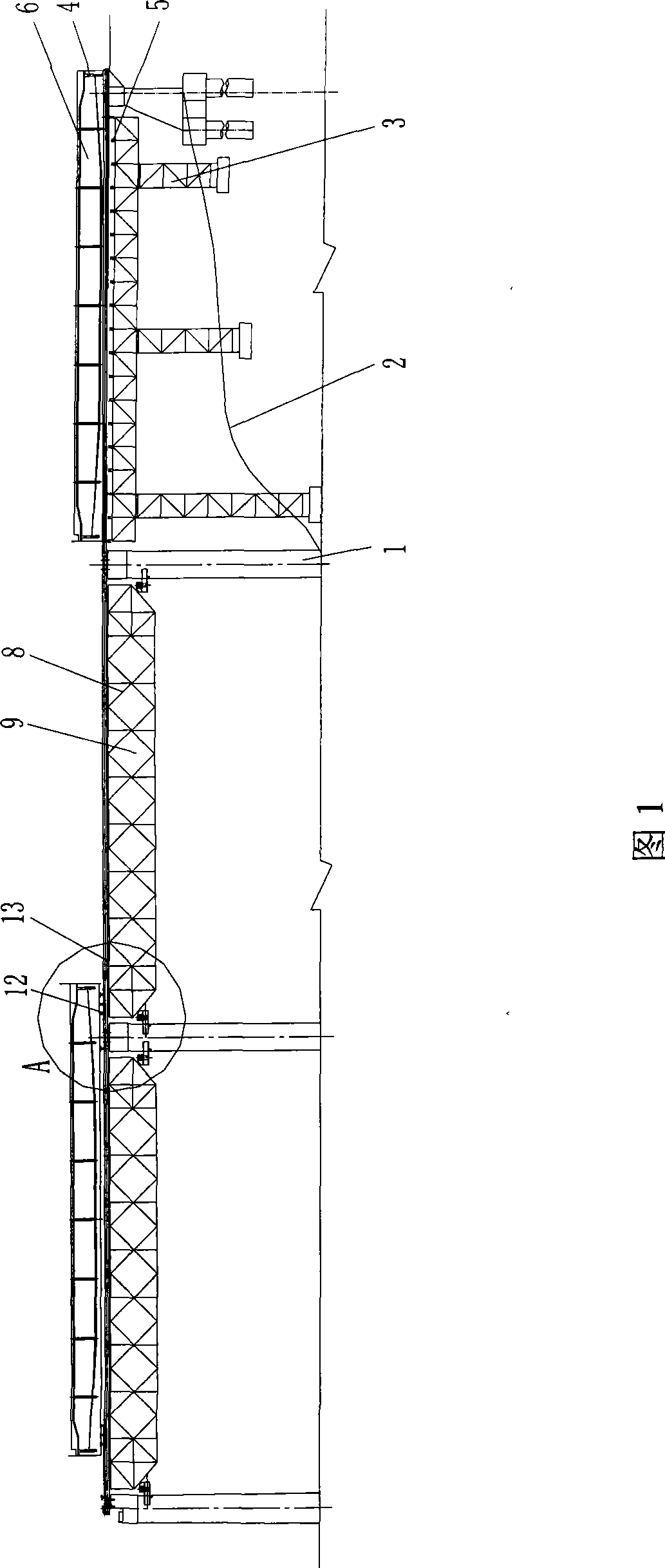

[0024] As shown in Figure 1, a bridge erection method, after each pier is built at the design position, the bridge erection is carried out according to the following steps:

[0025] A. Process the slope surface 2 on the side of each bridge pier 1; install the beam section prefabricated support 3 between the two adjacent bridge piers of the side holes; 6 precast;

[0026] B. If figure 2 As shown, steel pipe scaffolding 7 is set up between every other adjacent two bridge piers; guide beams 9 are assembled with universal rods 8 on each steel pipe scaffolding 7; Lift to the design position and install between two adjacent piers 1, the two ends of the guide beam 9 are fixed on the cap beam embedded parts 11 of the piers;

[0027] C. Install the slideway 13 for the longitudinal sliding of the tackle 12 on the guide beam 9, install the slideway 13 for the transverse sliding of the tackle 12 on the pier top, and install a jack and a traction cable on the front end pier item;

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com