Piezoelectric type torsion driver

A driver, piezoelectric technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of complex structure, large magnetic leakage, poor versatility, etc. Achieve the effects of simple mechanical structure, low noise and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principle, structure and working process of the present invention will be further described below with reference to the accompanying drawings.

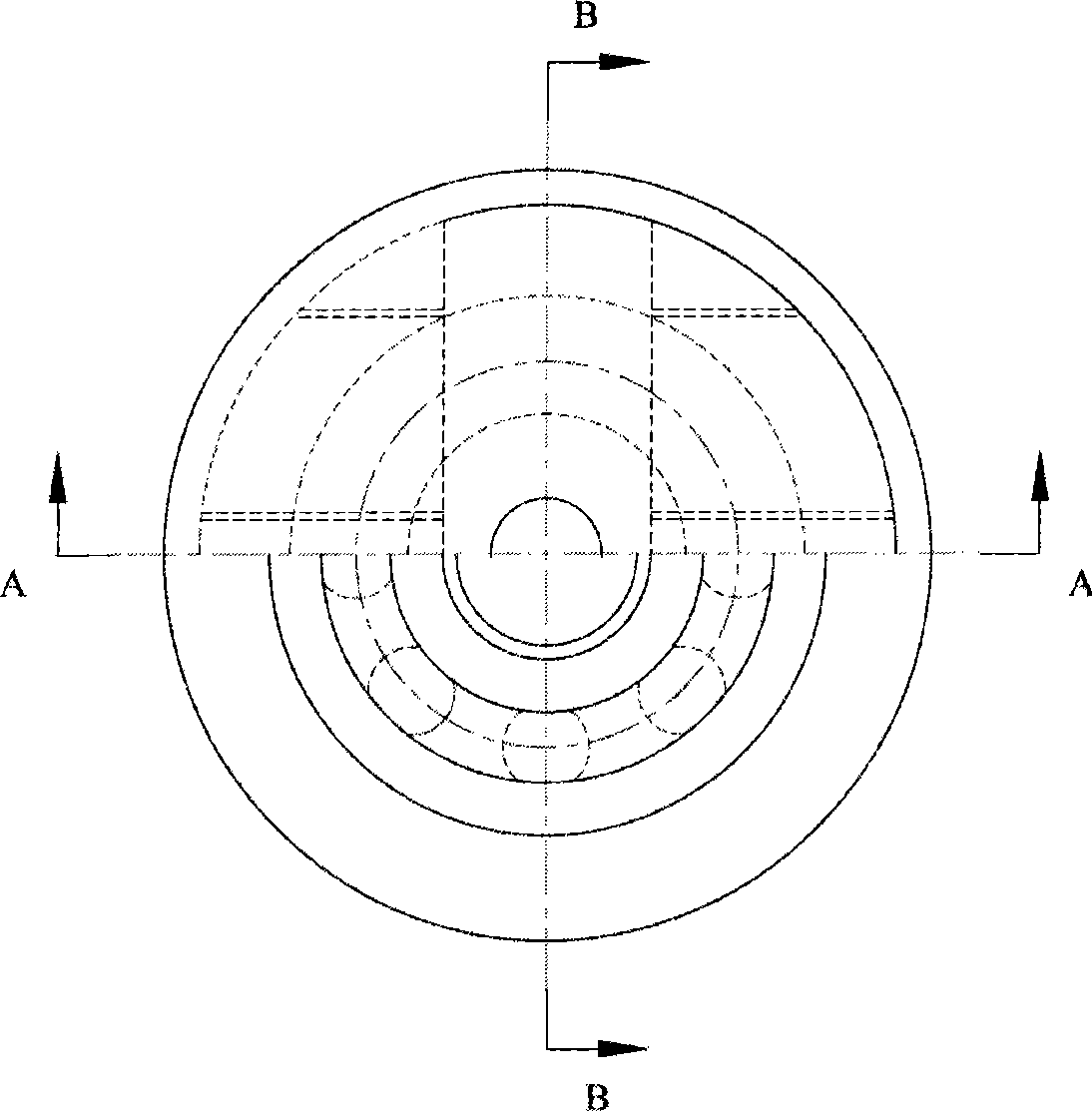

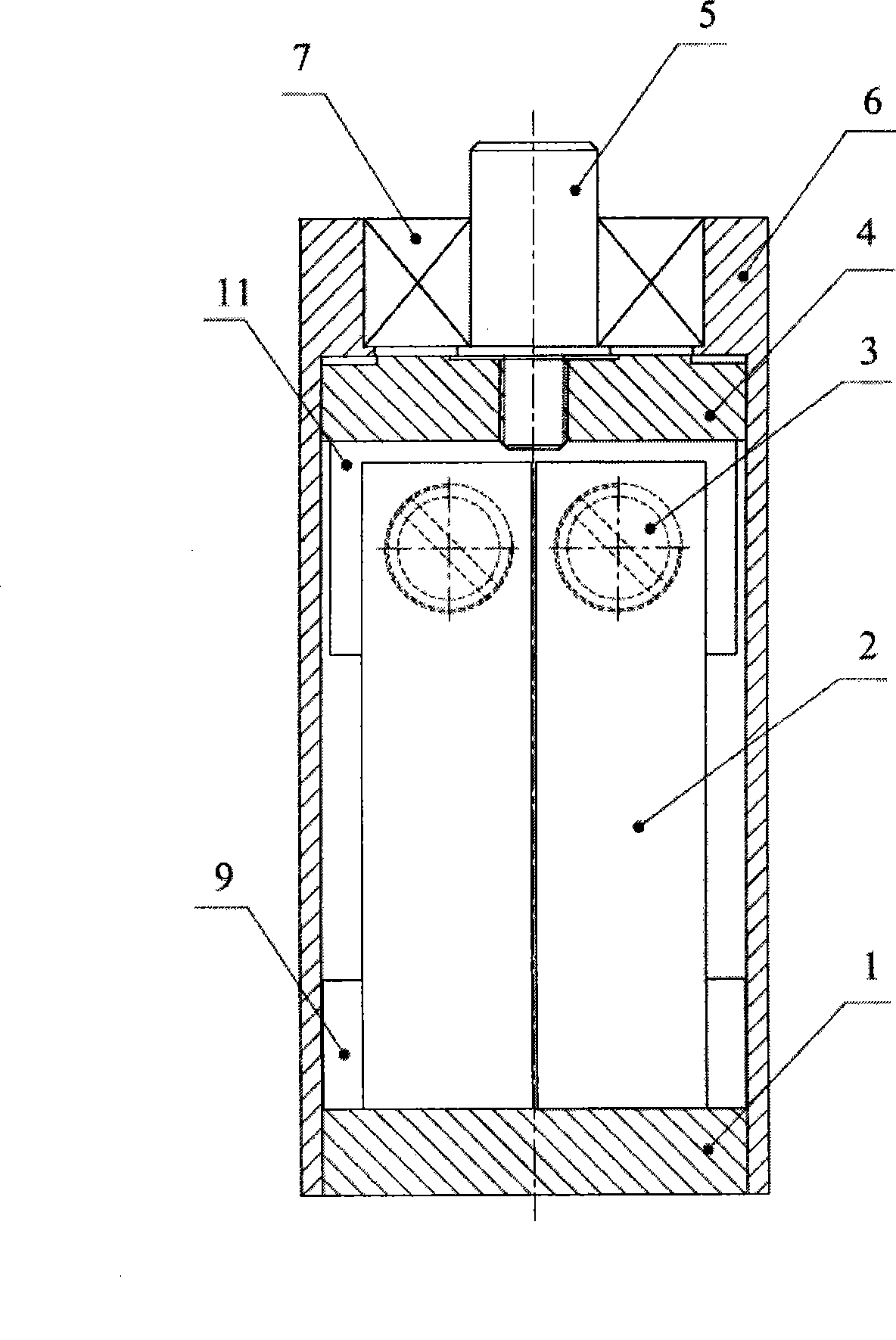

[0019] figure 1 is the top view (half section) of the piezoelectric torsional actuator, figure 2 is the cross-sectional view of the piezoelectric torsional actuator along the direction A-A', image 3 It is a cross-sectional view of the piezoelectric torsion driver along the B-B' direction. The driver consists of a base 1, a piezoelectric material adhesive sheet 2, a set screw 3, a motion conversion disc 4, an output shaft 5, a housing 6, a bearing 7 and Composed of fixing screws 8; the bonding method of the piezoelectric material bonding sheet 2 is as follows Figure 4 As shown, the direction of the arrow is the polarization direction of the piezoelectric material, and the part in the middle of the two piezoelectric material sheets is the metal foil lead-out electrode 16; Figure 5 is the front view of the motion conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com