Ginger beer formula and production process

A production process, ginger juice technology, applied in the direction of beer brewing, etc., can solve the problems of unscientific and reasonable manufacturing and processing technology, and achieve the effect of scientific and reasonable processing technology and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

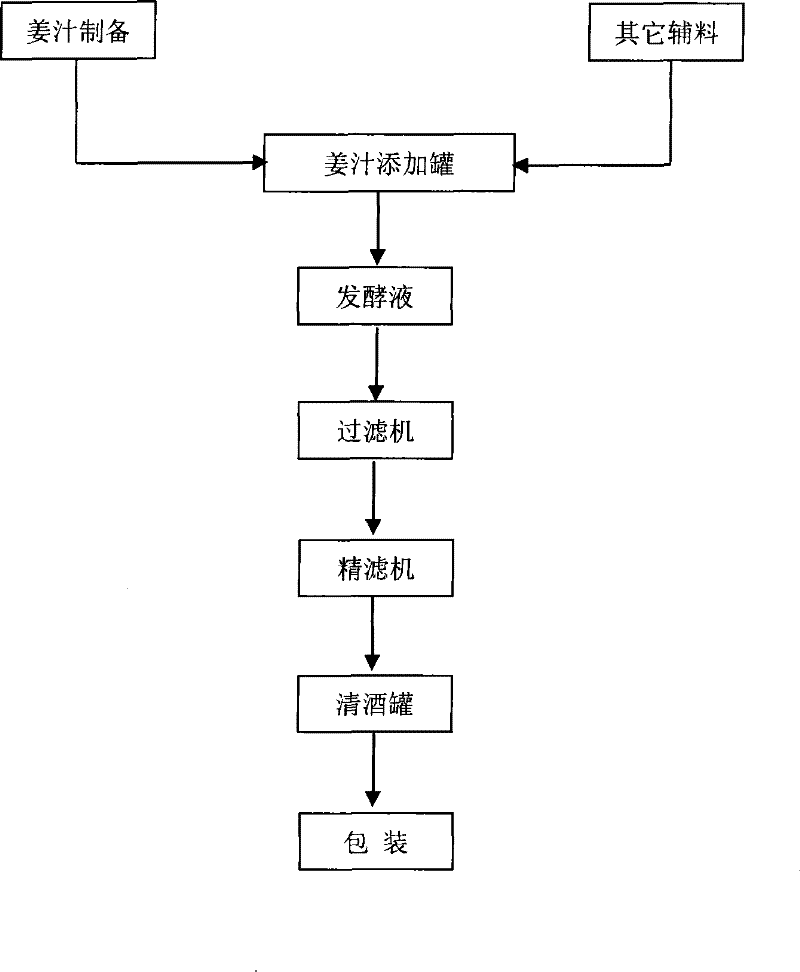

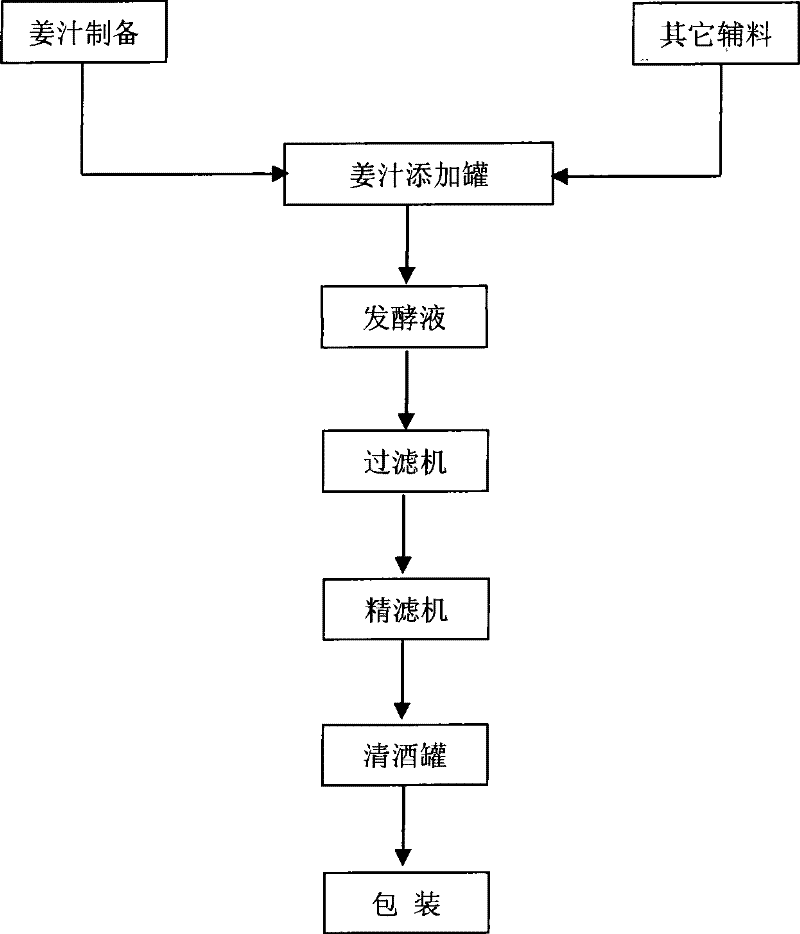

Image

Examples

Embodiment Construction

[0017] Concrete raw material formula sees table 1

[0018] a. Soak the ginger in clean water, and use a ginger washing machine or manually to wash away the dirt and impurities on the surface of the ginger; for the mildewed or damaged ginger, the mildewed or damaged surface should be cut off with a knife ;After cleaning, take out the ginger and drain it, then rinse and sterilize the ginger with hot water at 80-90°C for 5 minutes;

[0019] b. Put 23kg of ginger that has been washed and sterilized by hot water into a juicer to squeeze the juice, and put the squeezed ginger juice into the sedimentation tank for precipitation. At the same time, add CaCl 2 0.01kg and Vc0.025kg;

[0020] c. Clarify the above-mentioned ginger juice in the sedimentation tank for 8-10 hours, and remove the precipitated starch, protein and upper layer of ginger oil to obtain the ginger juice clarification;

[0021] d. Add 20 kg of hot water at 85-90°C to the ginger juice adding tank, then turn on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com