Bias cutter

An oblique cutting machine and pivot technology, which is used in metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems affecting the packaging volume of the oblique cutting machine, the packaging volume becomes larger, and the life of the torsion spring is shortened. The effect of packaging volume, smooth transmission, and shortened vertical distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below just with preferred embodiment, will illustrate the creative conception of the present utility model.

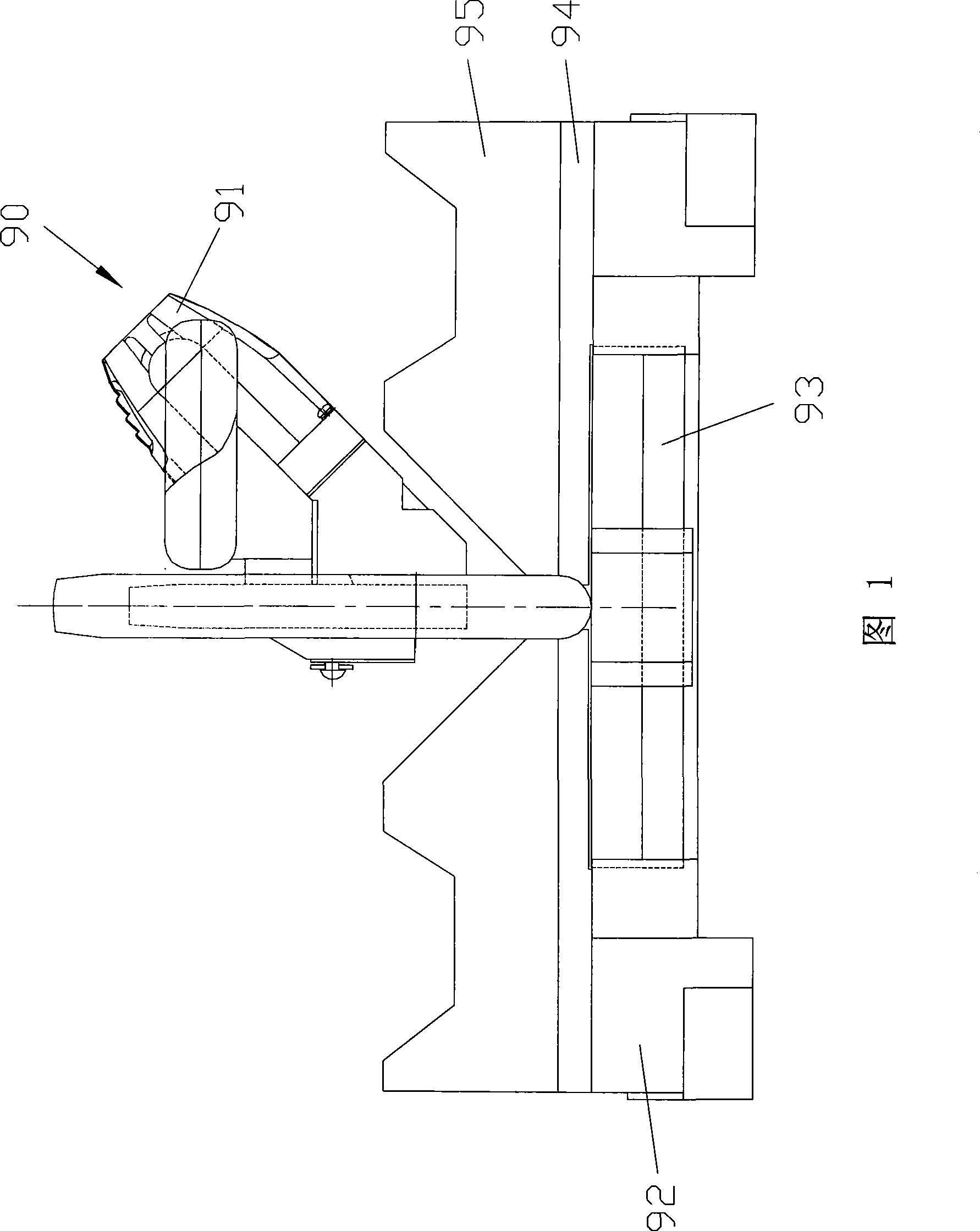

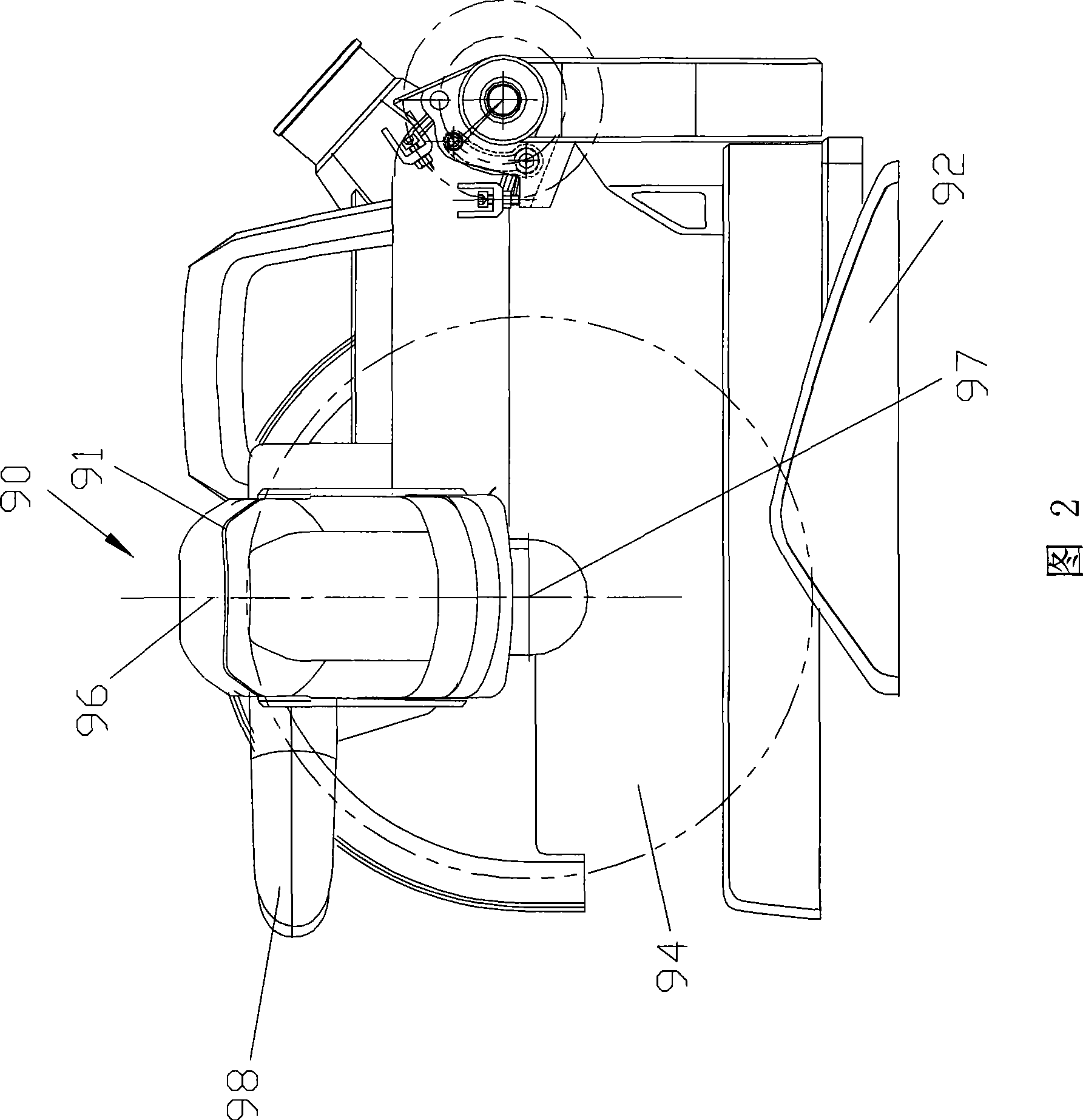

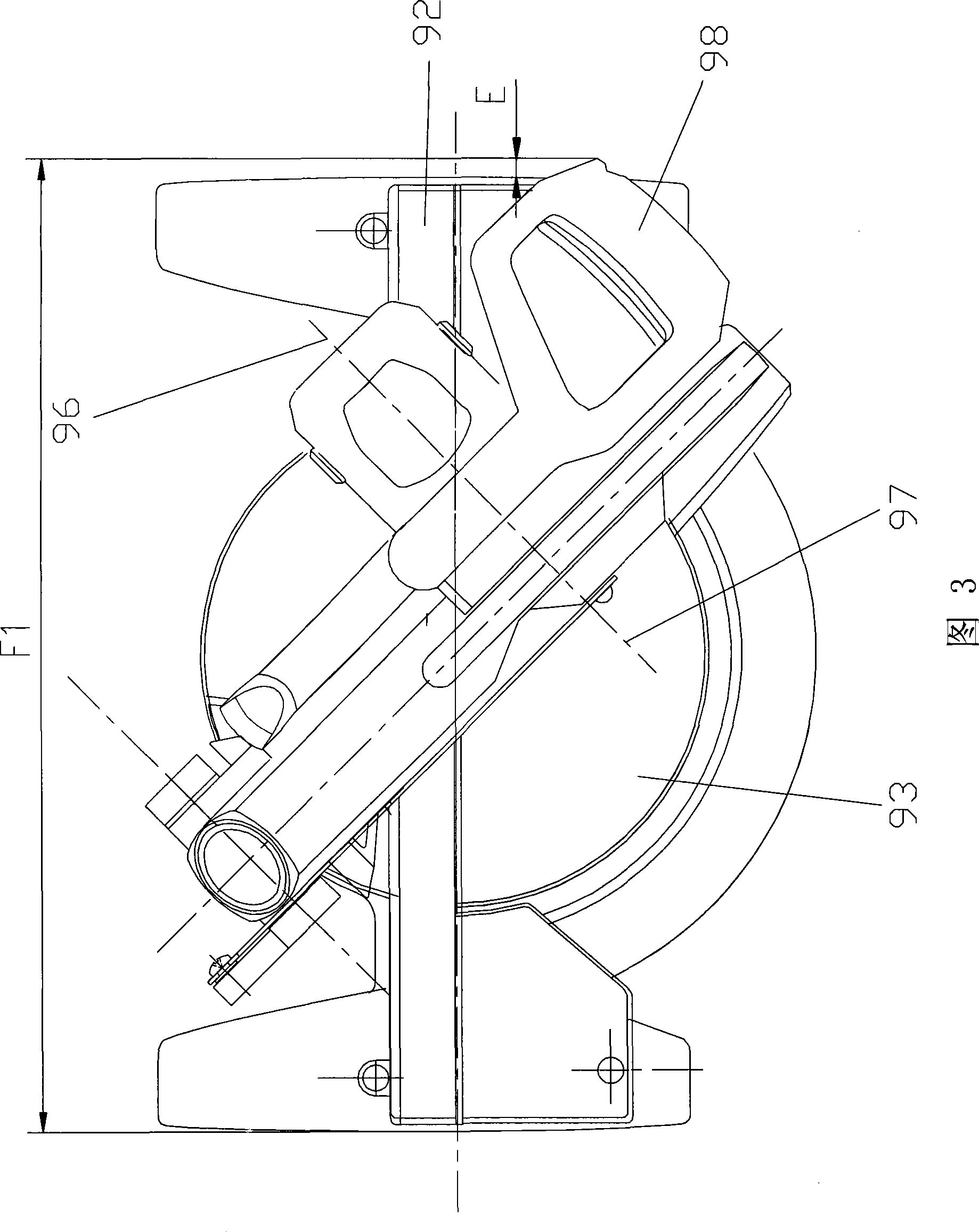

[0035] As shown in Figure 4, in the first preferred embodiment of the present invention, the bevel cutting machine includes a base 1, a workbench 8 that is rotatably connected to the base 1, a support arm 2 that is movably connected to the workbench 8, and a movable The saw mechanism 3 connected to the support arm 2, wherein the support arm 2 is pivotally arranged on the workbench 8 through the first pivot 21, and the saw mechanism 3 is pivotally arranged on the support arm 2 through the second pivot 31 Come up to realize the cutting workpiece. The base 1 has front and rear sides, wherein the front side is close to the operator, and the rear side is opposite to the front side. The second pivot 31 is used as the pivot shaft of the saw mechanism 3, on which a torsion spring (not shown) is also sleeved, so that the operator presses the saw mechanism 3 to pivot, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com