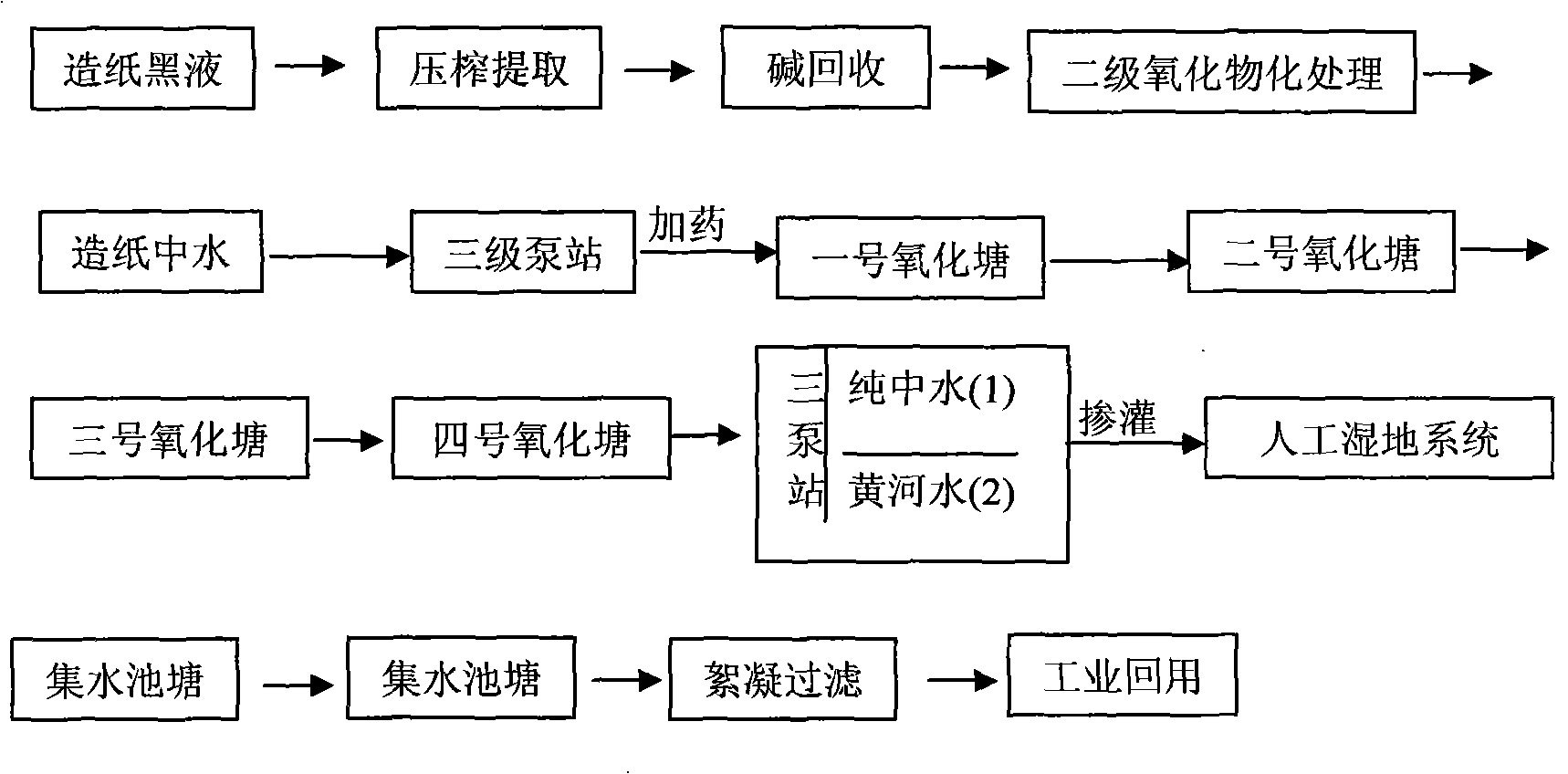

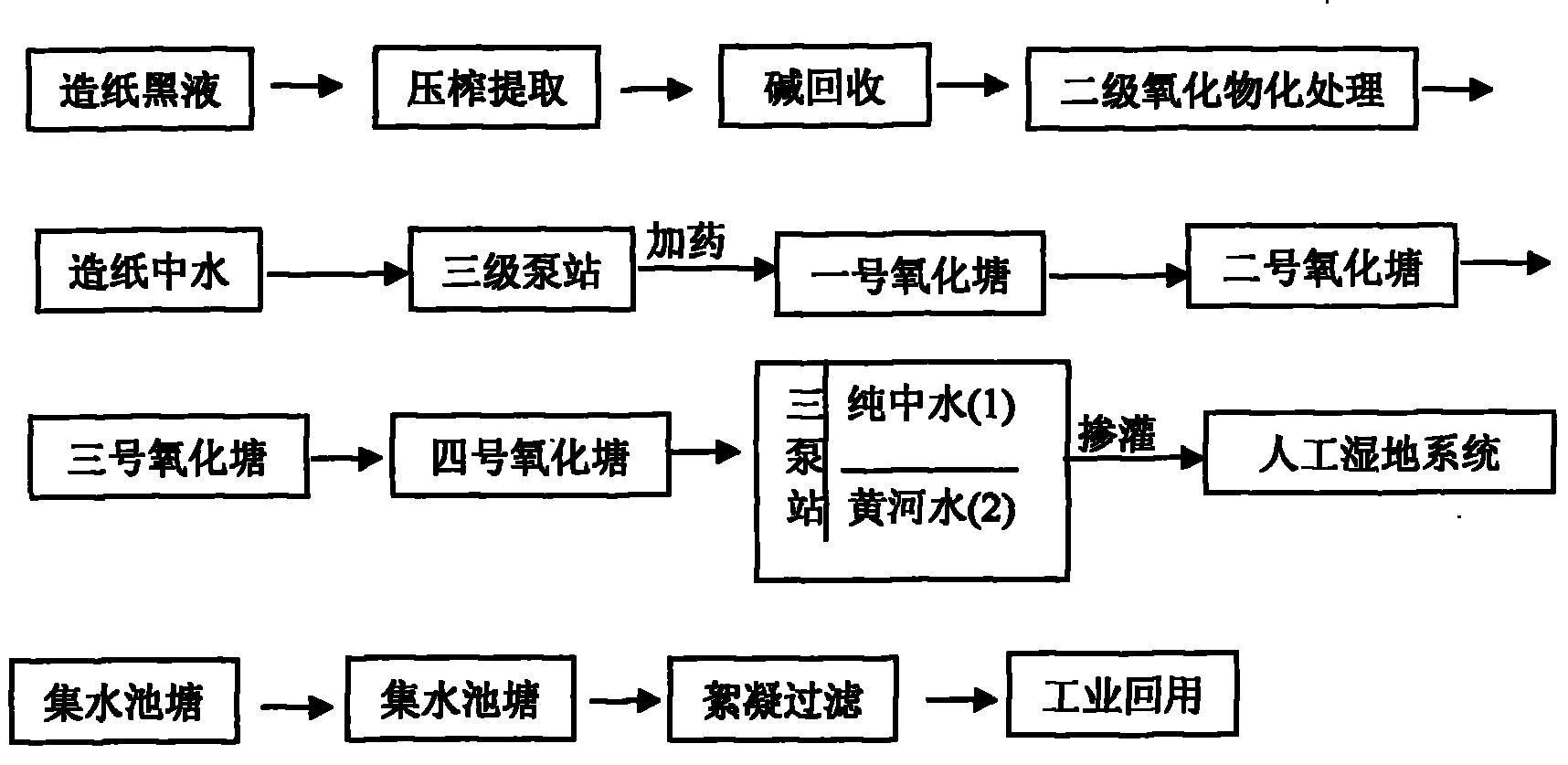

Method for deeply treating papermaking wastewater

A papermaking sewage and advanced treatment technology, which is applied in the direction of energy wastewater treatment, process wastewater treatment, aerobic and anaerobic process treatment, etc., can solve the problems of high treatment cost, serious secondary pollution, short life, etc., and achieve cost reduction , low-cost resource recycling, low power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the desert wasteland, according to the requirements of the purification function and the amount of sewage to be treated, four-stage oxidation ponds with corresponding capacities are designed and constructed, specifically, the first-stage anaerobic pond, the second-stage facultative pond, the third-stage aerobic pond and the fourth-stage aerated aquatic biological oxidation pond, of which

[0015] (1) Level 1 anaerobic pond

[0016] The anaerobic pond is suitable for treating high-concentration organic wastewater, with an average water depth of 5.5-7.5m and a storage capacity of 2.63 million cubic meters. A scum layer is formed on the surface of the pond, and the dissolved oxygen in the pond water is extremely low. There is basically no algae growth in the pond, and the organic matter is mainly decomposed into CH by anaerobic microbial activities. 4 (carbon) and CO 2 .

[0017] Table 1 Design parameters of anaerobic pond

[0018] name

parameter

Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com