Slice material conveying device and image forming device

A material conveying device and sheet technology, applied in thin material processing, transportation and packaging, electrical recording technology using charge graphics, etc., can solve problems such as insufficient conveying force, bearing deviation, and inability to obtain pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

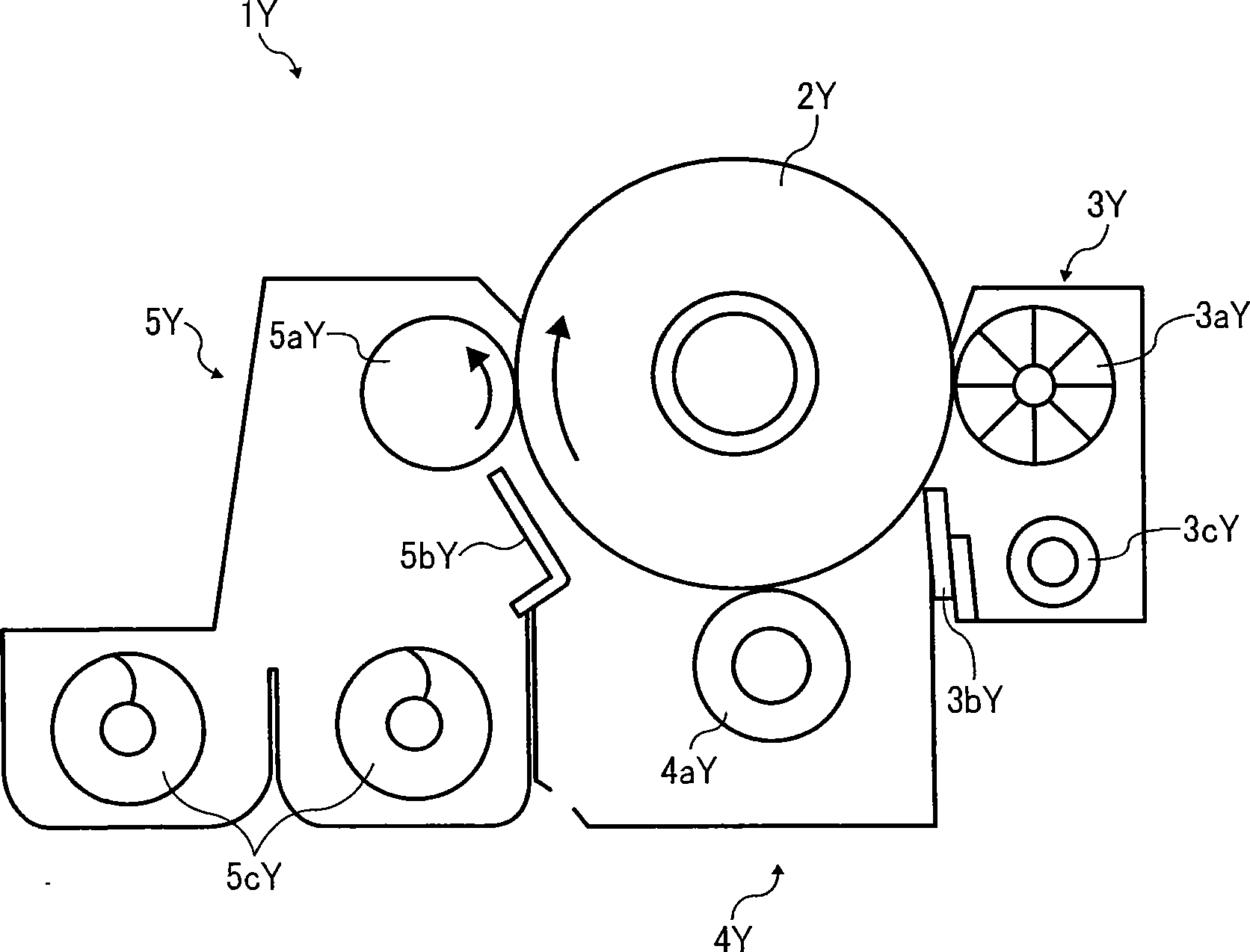

[0052] Hereinafter, a line type color laser printer (hereinafter simply referred to as printer 500 ) in which a plurality of photoreceptors are arranged in parallel will be described as an example of an image forming apparatus to which the present invention is applied.

[0053] figure 1 It is a schematic structural diagram of the printer 500 according to this embodiment. The printer 500 includes an image forming unit 200 , a paper feeding unit 300 on which the image forming unit 200 is placed, and the like.

[0054] Inside the device of the printer 500, four image forming units 1 (Y, C, M, Bk) are provided as image forming devices for forming yellow (Y), cyan (C), magenta (M), black (Bk) Various images. The image forming section 1 (Y, C, M, Bk) includes drum-shaped photoreceptors 2 (Y, C, M, Bk) respectively, and the four photoreceptors 2 (Y, C, M, Bk) are formed in the image forming section. 200 are arranged side by side at the same interval. When the printer 500 operates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com