Electric coiling spacing detection device

A detection device, electric rolling technology, applied in projection devices, winding strips, door/window protection devices, etc., can solve problems such as inaccurate positioning, damage to electric roller shutters, and swimming, and reduce maintenance costs. The effect of reliable safety guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described:

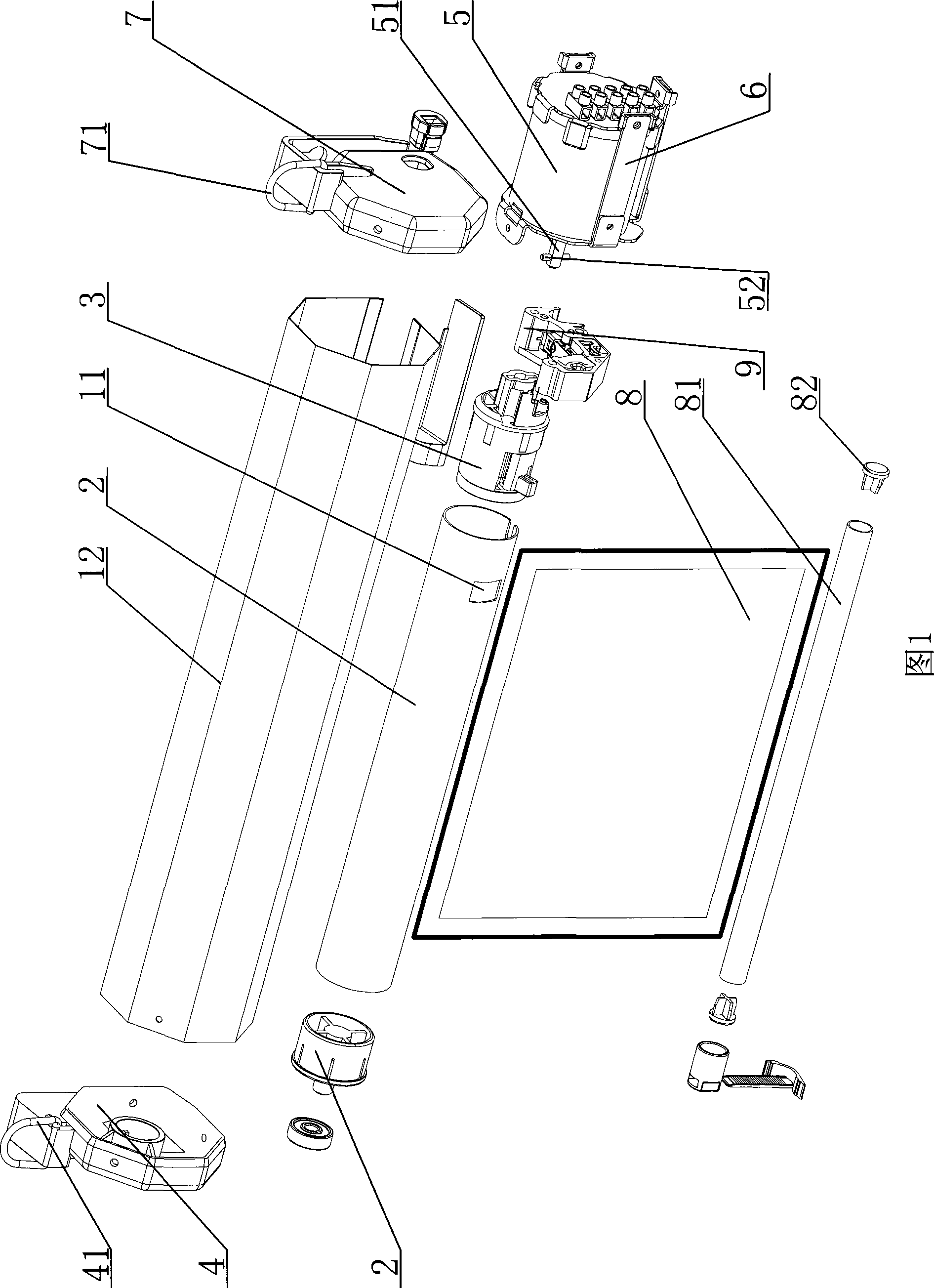

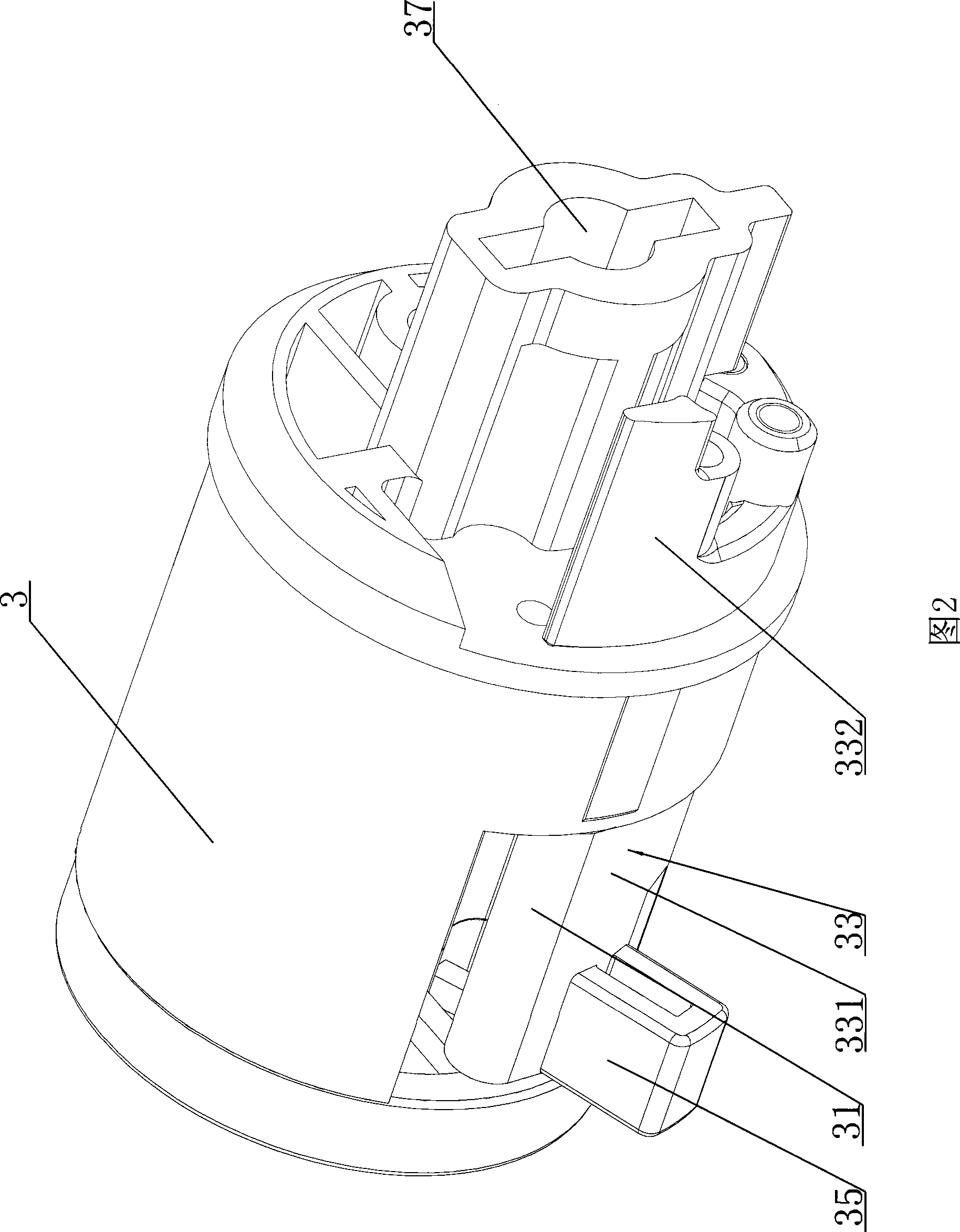

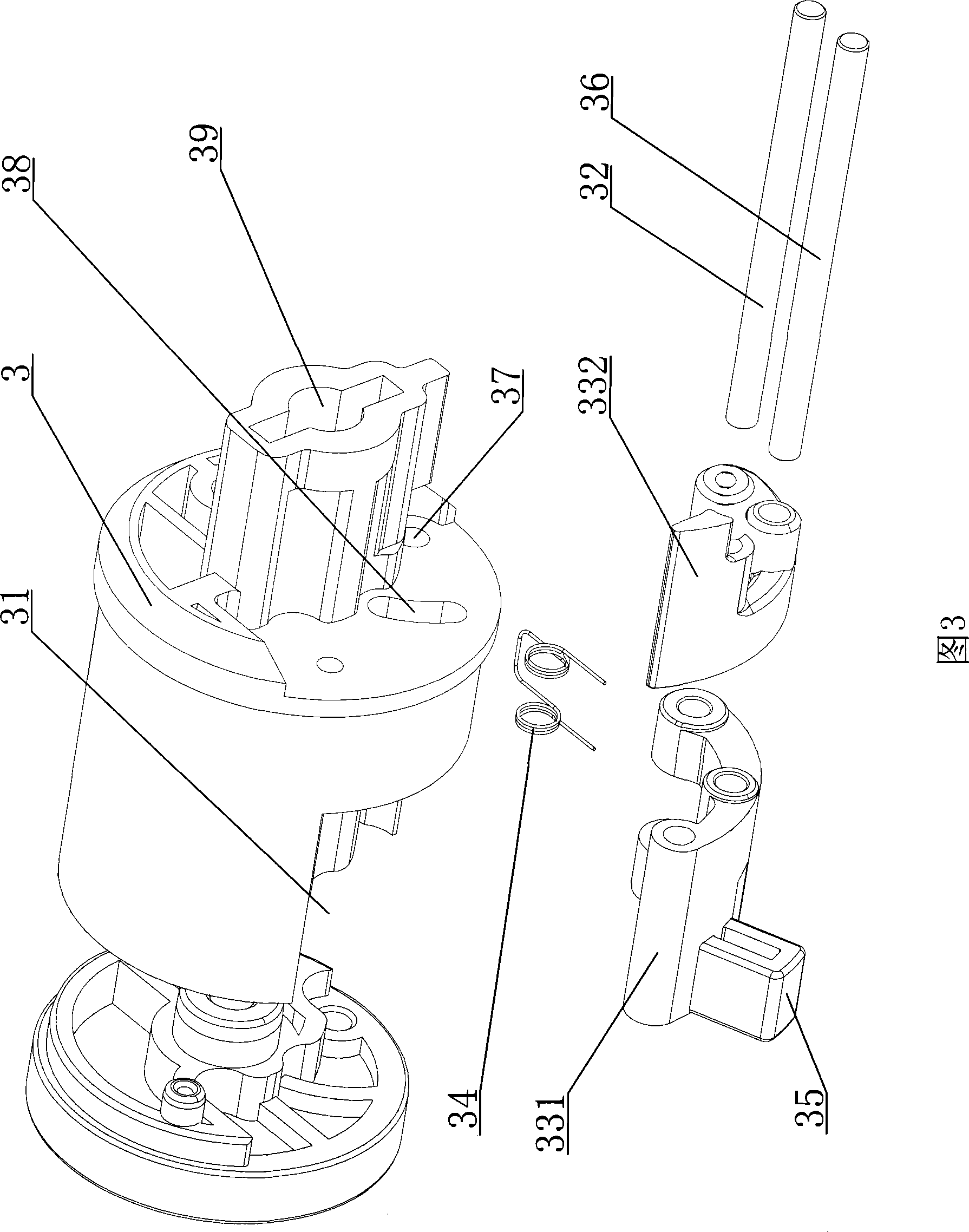

[0014] As shown in Figures 1 to 5, the electric winding limit detection device includes: a core tube 1. In actual use, the core tube 1 is installed in a casing 12, and an opening 11 is provided on the core tube 1. A core tube plug 2 and a core tube rotor 3 are respectively arranged inside the two ends of the core tube 1, and one end of the core tube 1 is movably set in the left end cover 4 through the core tube plug 2, and the other end of the core tube 1 is set through the core tube rotor 3 and the set The output shaft 51 of the synchronous motor 5 in the damping motor base 6 is connected, and the specific connection method is: the output shaft 51 of the synchronous motor 5 is fixedly arranged in the shaft hole 39 on the other end of the core tube rotor 3 through a pin shaft 52 , one end of the damping motor base 6 is fixedly arranged in the right end cover 7, one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com