Congestion type busway jack tapping-off pile head

A technology for tapping pile heads and busway, which is applied in the installation of busbars, welding/welding connections, electrical components, etc., which can solve the problems of easy deformation of pile heads, unnecessary, high cost of tinning, etc., to reduce costs and improve reliability non-toxic, not easily deformed by heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

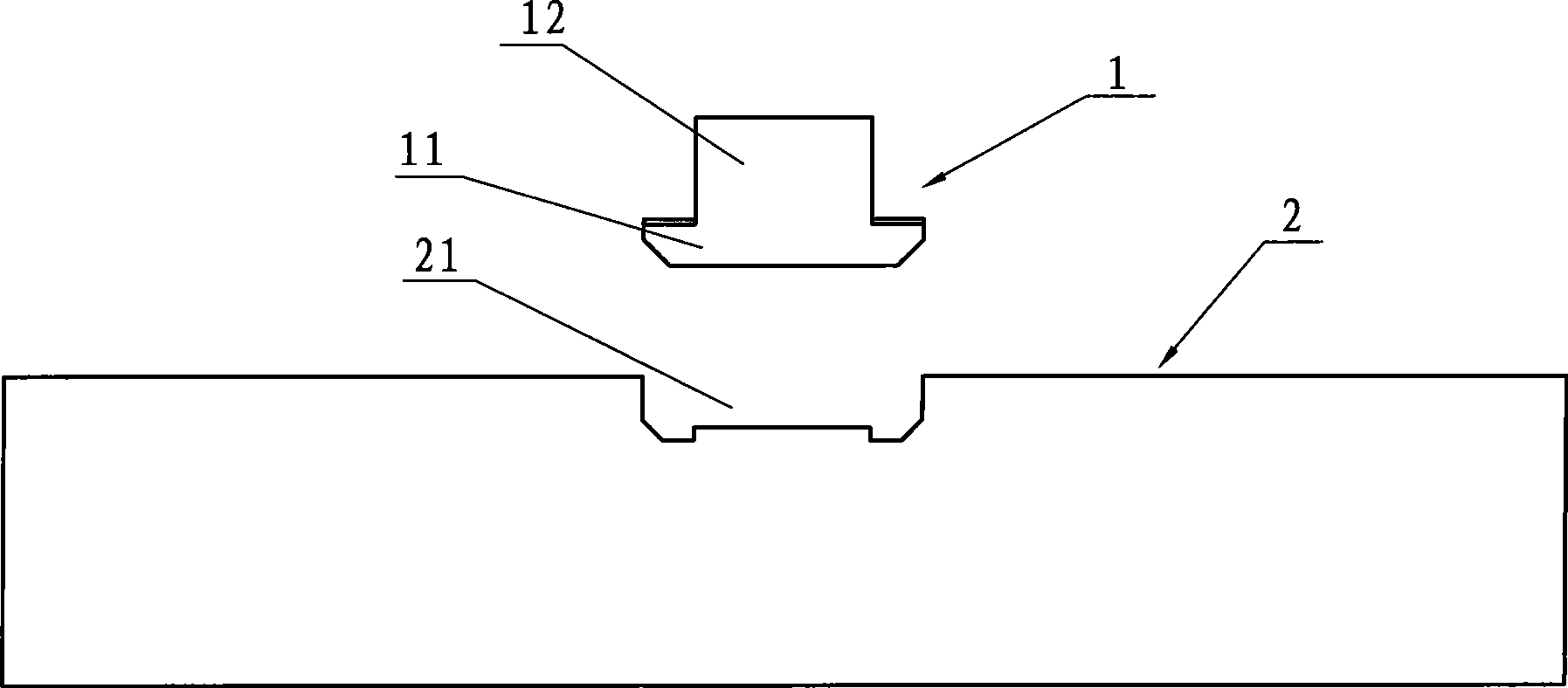

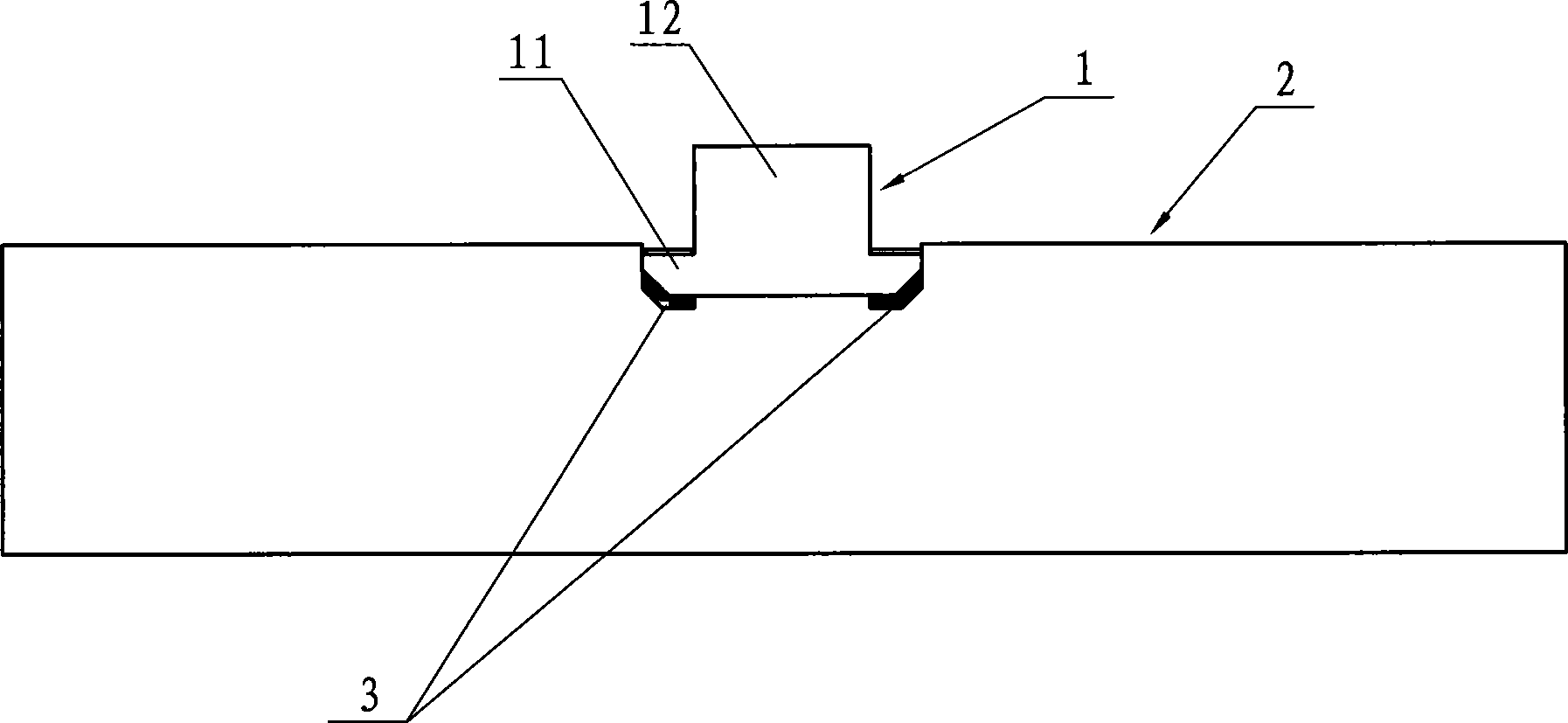

[0010] As shown in the figure, the tap head of the intensive bus duct socket includes a pile head 1 and a busbar 2, and a notch 21 for the pile head to be embedded is opened on the edge of the busbar. The overall pile head has an "inverted T-shaped" structure, that is, it is composed of a wider root 11 and a narrower main body 12 . The root 11 of the pile head is embedded in the notch 21 of the busbar, and a welded connection section 3 is respectively arranged between the two sides of the pile head and the busbar. The lower section of the root 11 of the pile head is "inverted trapezoid", and the welded connection section 3 extends from the two waist parts of the "inverted trapezoid" structure to the two sides of the bottom edge, so that a larger welded connection area can be obtained to meet the strength and load requirements. flow performance requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com