Method for generating high repeat frequency and high power optical frequency comb

An optical frequency comb, high repetition frequency technology, applied in the direction of the structure/shape of the active medium, can solve the problems of thermal effect accumulation obstacles, difficult development process, etc., to achieve the effect of simple structure, easy operation, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] The features of the present invention and other related features will be further described in detail below in conjunction with the accompanying drawings through embodiments, so as to facilitate the understanding of those skilled in the art:

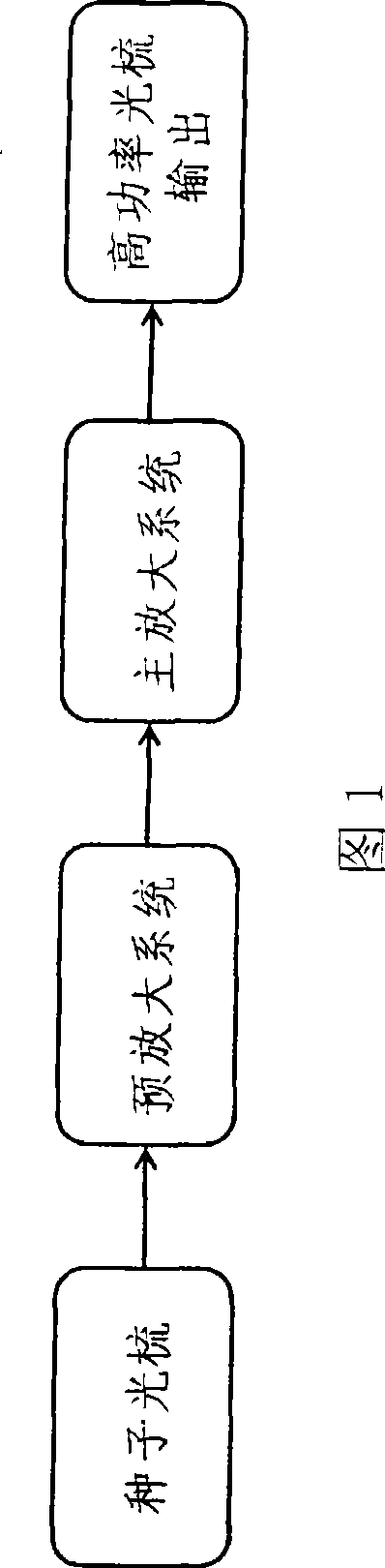

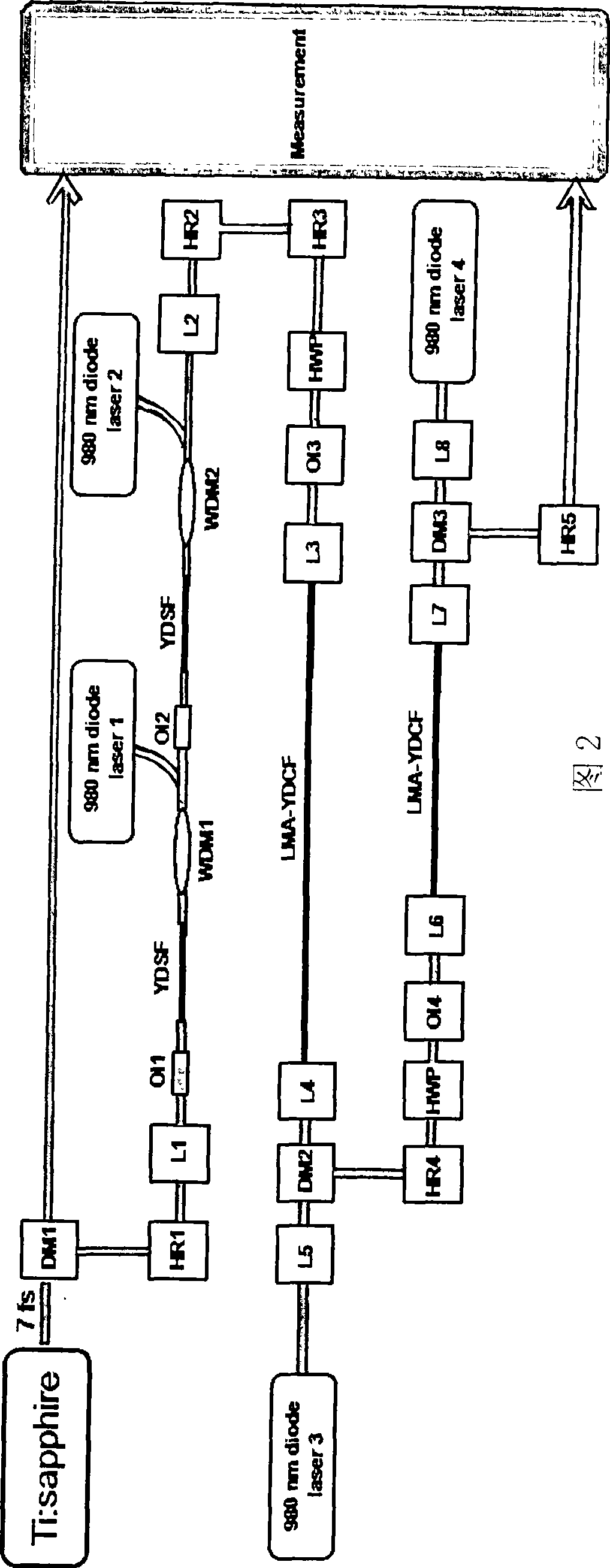

[0016] As shown in Figures 1 and 2, the labels in the figures represent: signal laser Ti:sapphire, dichroic mirror DM1, high reflection mirror HR1, lens L1, isolator OI1, 0.6m ytterbium-doped single-mode fiber YDSF, wavelength division multiplexer WDM1, 980nm laser diode 980nm diode laser 1, isolator OI2, 2m ytterbium-doped single-mode fiber YDSF, wavelength division multiplexer WDM2, 980nm laser diode 980nm diode laser 2, lens L2, high reflection mirror HR2, high reflection mirror HR3 , half-wave plate HWP, isolator OI3, lens L3, 1.2m large mode field ytterbium-doped double-clad fiber LMA-YDCF, lens L4, dichroic mirror DM2, lens L5, 980nm laser diode 980nm diode laser 3, high reflection mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com