Method for producing potassium diformate by reaction of aminic acid and mixed base

A technology of potassium diformate and mixed alkali, which is applied in the preparation of carboxylate, etc., can solve the problems of production personnel injury, difficult process control, severe process, etc., achieve the effect of low equipment requirements, easy process control, and increase product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

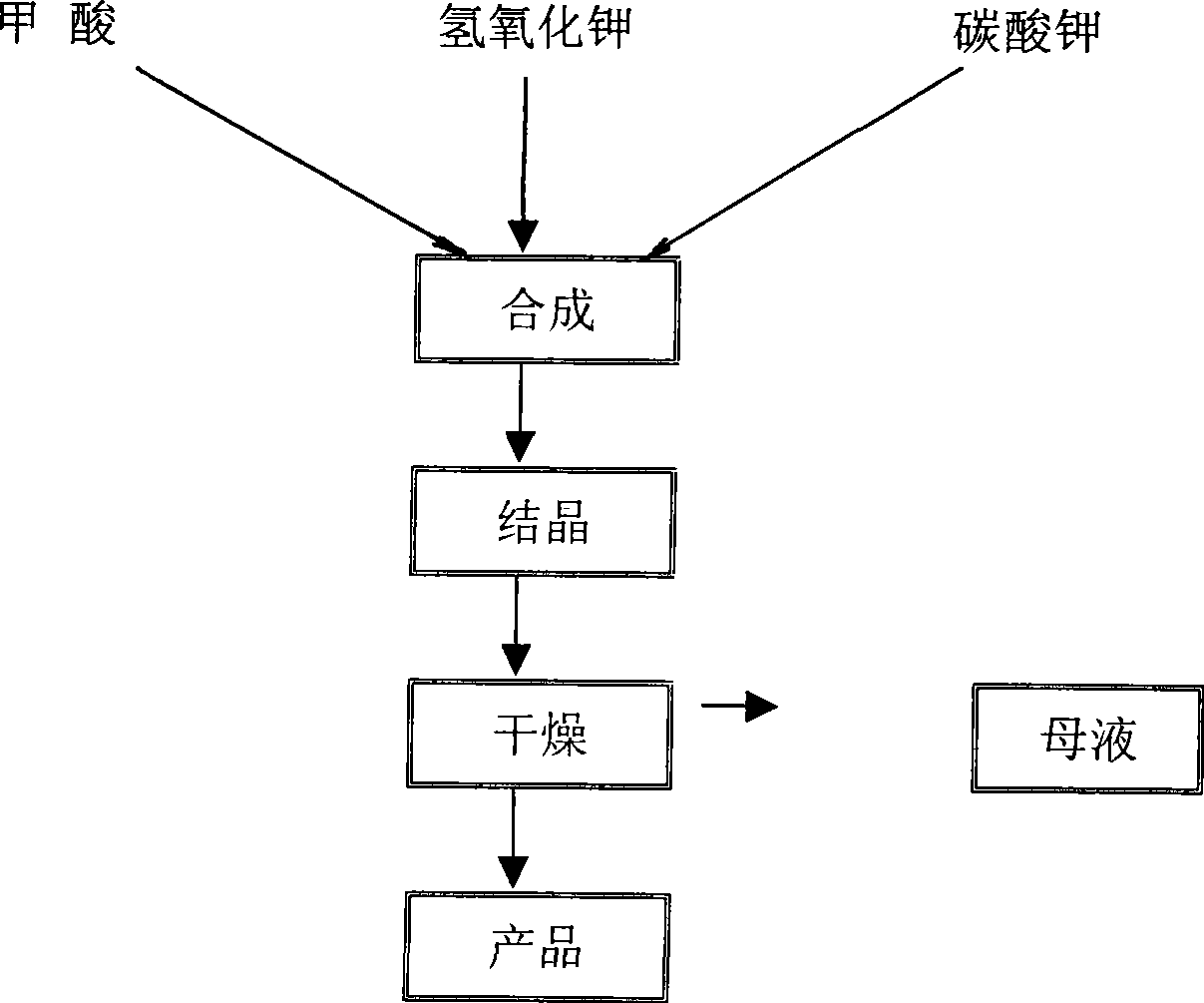

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: formic acid and potassium hydroxide and salt of wormwood produce potassium diformate

[0014] Take 195.4kg of formic acid solution (≥91%) and add it to a 1000L jacketed enamel reaction kettle with a stirring device, turn on the cooling water, and slowly add 196.4kg of potassium hydroxide solution (≥50%) and 226.8kg of carbonic acid Potassium solution (≥50%) with CO in process 2 The gas is released; then slowly add 455.8kg of formic acid solution, stir, control the temperature at 62±2°C, and react for 4 to 5 hours. Stir to cool down, and crystallize out. The potassium diformate product is obtained by crystallization and drying, and the supernatant is reused for the next batch of reactions.

[0015] Add the centrifuged supernatant to the reaction kettle first, then slowly add 196.4kg of potassium hydroxide, 195.4kg of formic acid, 226.8kg of potassium carbonate, and 455.8kg of formic acid in turn under stirring, stir and control the temperature at 62±2°C, ...

Embodiment 2

[0017] Embodiment 2, formic acid and potassium hydroxide and salt of wormwood produce potassium diformate

[0018] Add 186.3kg of formic acid solution (≥50%) to a 1000L jacketed enamel reaction kettle with a stirring device, turn on the cooling water, and slowly add 248.0kg of potassium hydroxide solution (≥70%) and 154.0kg of potassium carbonate under stirring solid (≥99%), then slowly add 434.7kg of formic acid solution, after the addition is complete, stir, control the temperature at 62±2°C, and react for 4 to 5 hours. The reactant was concentrated in vacuo; the concentrated solution was stirred and cooled until crystals were precipitated. The potassium diformate product is obtained by crystallization and drying, and the supernatant is reused for the next batch of reactions.

[0019] Add the centrifuged supernatant to the reaction kettle first, then slowly add 248.0kg of potassium hydroxide, 186.3kg of formic acid, 154.0kg of potassium carbonate, and 434.7kg of formic acid...

Embodiment 3

[0021] Embodiment 3, formic acid and potassium hydroxide and salt of wormwood produce potassium diformate

[0022] Add 185.3kg of formic acid solution (≥70%) to a 1000L jacketed enamel reaction kettle with stirring device, turn on the cooling water, and slowly add 297.0kg of potassium hydroxide solution or solid (≥50%), 83.7kg Potassium carbonate solid (≥99%), then slowly add 432.4kg of formic acid solution, after the addition is complete, stir, temperature control at 62±2°C, and react for 4 to 5 hours. The reactant was concentrated in vacuo; the concentrated solution was stirred and cooled until crystals were precipitated. Crystallization and drying to obtain potassium diformate product. The mother liquor continues to be recycled to the next batch of reactions.

[0023] Add the centrifuged supernatant to the reaction kettle first, then slowly add 297.0kg of potassium hydroxide, 185.3kg of formic acid, 83.7kg of potassium carbonate, and 432.4kg of formic acid in sequence und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com