Low-viscosity skin lotion and preparation method thereof

A skin care milk and low-viscosity technology, applied in the field of low-viscosity skin care lotion and the manufacture of the low-viscosity skin care lotion, can solve the problems of complex equipment, difficult control of manufacturing process, pouring out, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Oil phase raw materials:

[0039]

[0040] Water Phase Raw Materials:

[0041]

[0042] Preparation:

[0043] First weigh each component according to the above formula, and then put ① into Add all the ingredients into the oil phase pot, heat up to 90°C-95°C, put Put the ingredients into the water phase pot, heat up to 90°C-95°C, then vacuum pump the oil phase pot raw materials and water phase pot raw materials into the emulsification pot, homogenize for 10 minutes, and the homogenization speed is 2800r / min, then cool the liquid to 45°C, add Continue to cool the liquid to 40°C, then it can be discharged from the emulsification pot.

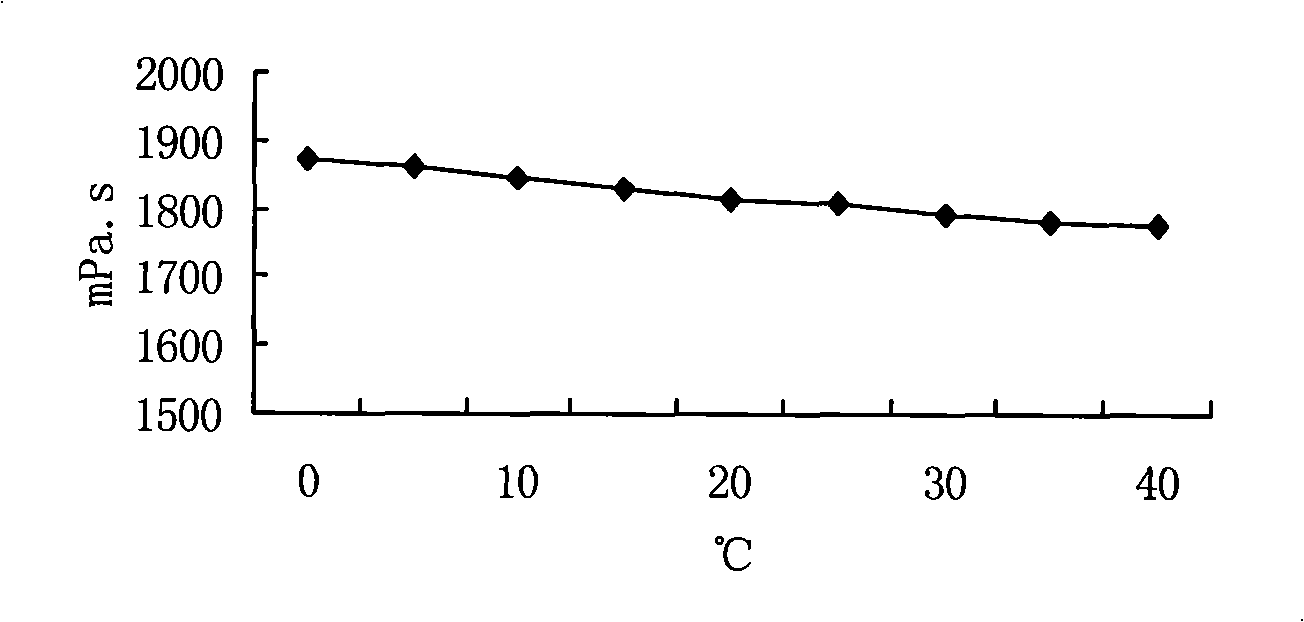

[0044] Detection: Measure the viscosity of the emulsion with a BROOKFIELD viscometer at room temperature 25°C. The viscosity of the emulsion is 1809mPa.s. After the emulsion is kept at a temperature of 38±1°C for 1 hour, it is centrifuged in a centrifuge at a speed of 2000r / min for 30 minutes. The emulsion is stable. layered. ...

Embodiment 2

[0048] Oil phase raw materials:

[0049]

[0050] Water Phase Raw Materials:

[0051]

[0052]

[0053] Preparation:

[0054] First weigh each component according to the above formula, and then put ① into Add all the ingredients into the oil phase pot, heat up to 90°C-95°C, put Put the ingredients into the water phase pot, heat up to 90°C-95°C, then vacuum pump the oil phase pot raw materials and water phase pot raw materials into the emulsification pot, homogenize for 10 minutes, and the homogenization speed is 2800r / min, then cool the liquid to 45°C, add Continue to cool the liquid to 40°C, then it can be discharged from the emulsification pot.

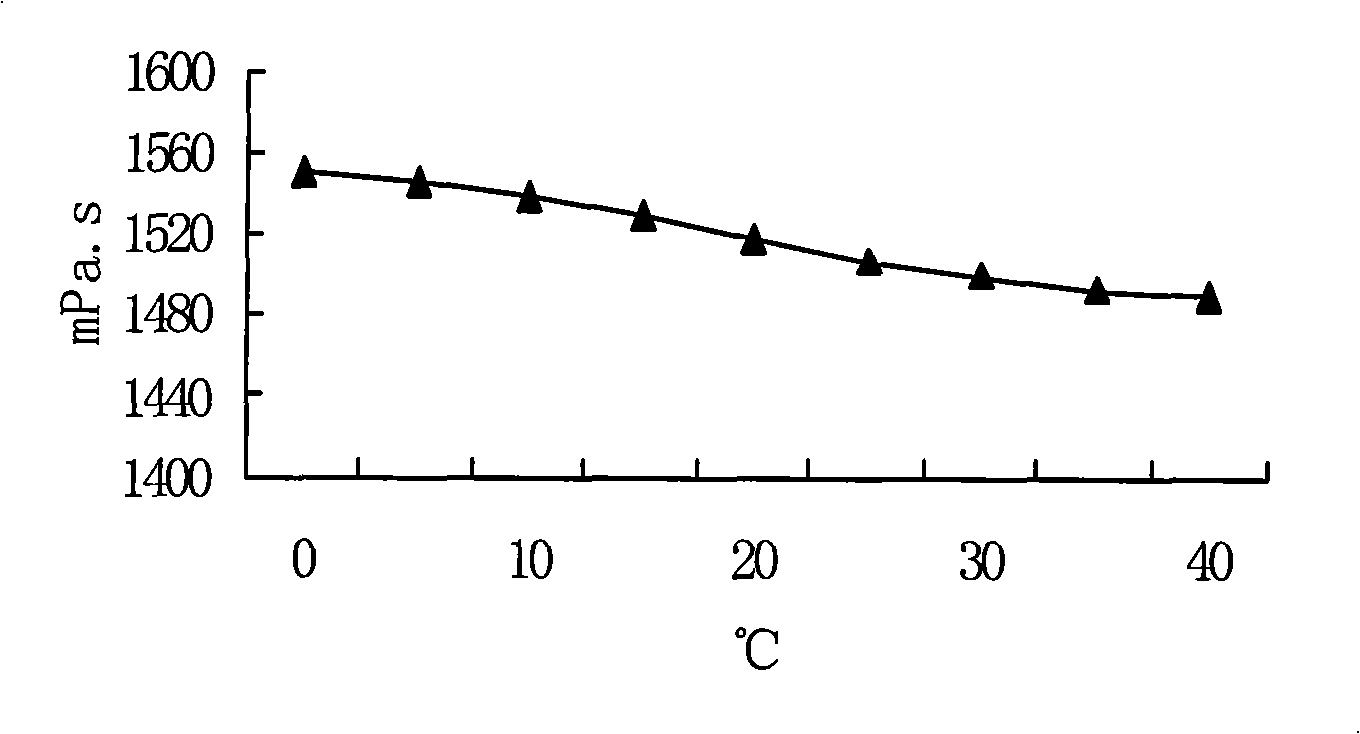

[0055] Detection: Measure the viscosity of the emulsion with a BROOKFIELD viscometer at room temperature 25°C. The viscosity of the emulsion is 1507mPa.s. After the emulsion is kept at a constant temperature of 38±1°C for 1 hour, it is centrifuged in a centrifuge at a speed of 2000r / min for 30 minutes. The emulsion i...

Embodiment 3

[0059] Oil phase raw materials:

[0060]

[0061]

[0062] Water Phase Raw Materials:

[0063]

[0064] Preparation:

[0065] First weigh each component according to the above formula, and then put ① into Add all the ingredients into the oil phase pot, heat up to 90°C-95°C, put Put the ingredients into the water phase pot, heat up to 90°C-95°C, then vacuum pump the oil phase pot raw materials and water phase pot raw materials into the emulsification pot, homogenize for 10 minutes, and the homogenization speed is 2800r / min, then cool the liquid to 45°C, add Continue to cool the liquid to 40°C, then it can be discharged from the emulsification pot.

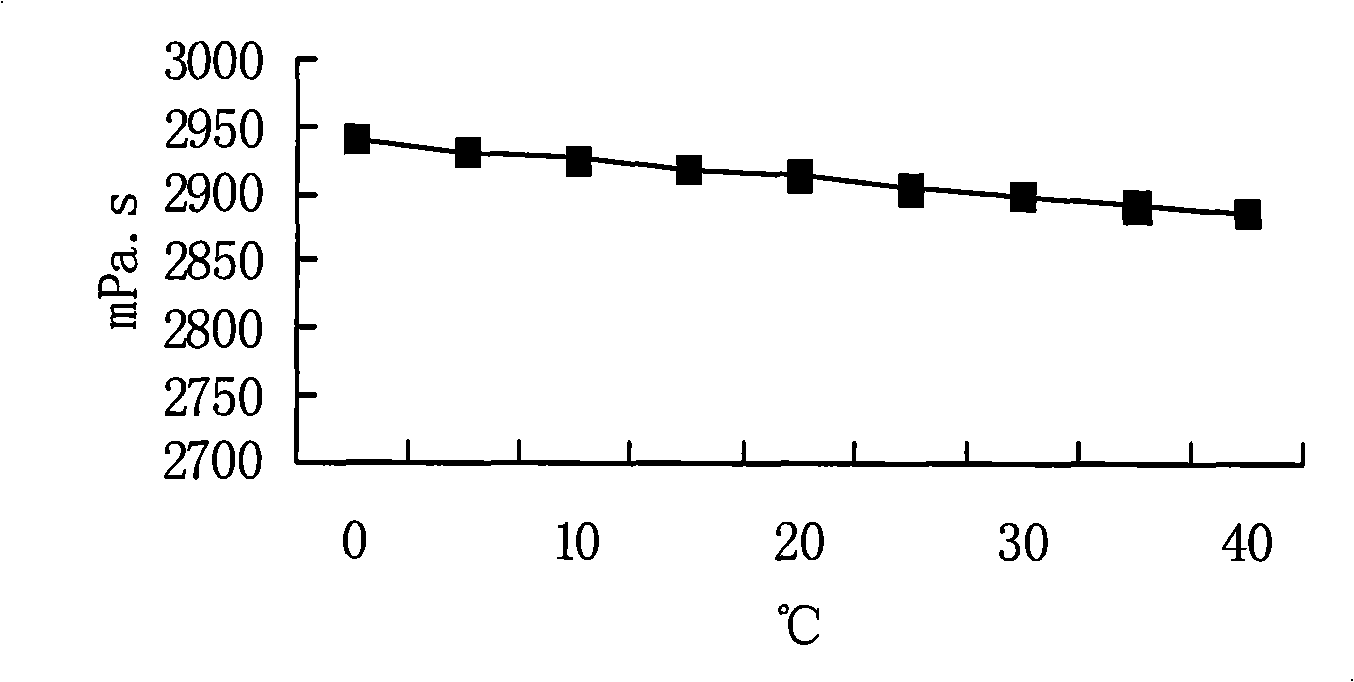

[0066] Detection: Measure the viscosity of the emulsion with a BROOKFIELD viscometer at room temperature 25°C. The viscosity of the emulsion is 2905mPa.s. After the emulsion is kept at 38±1°C for 1 hour, it is centrifuged in a centrifuge at a speed of 2000r / min for 30 minutes. The emulsion is stable. layered.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com