Composite bathtub

A bathtub and mold technology, applied in the field of sanitary ware, can solve problems such as poor safety, too smooth, high surface hardness, etc., and achieve the effects of convenient processing, improved comfort, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

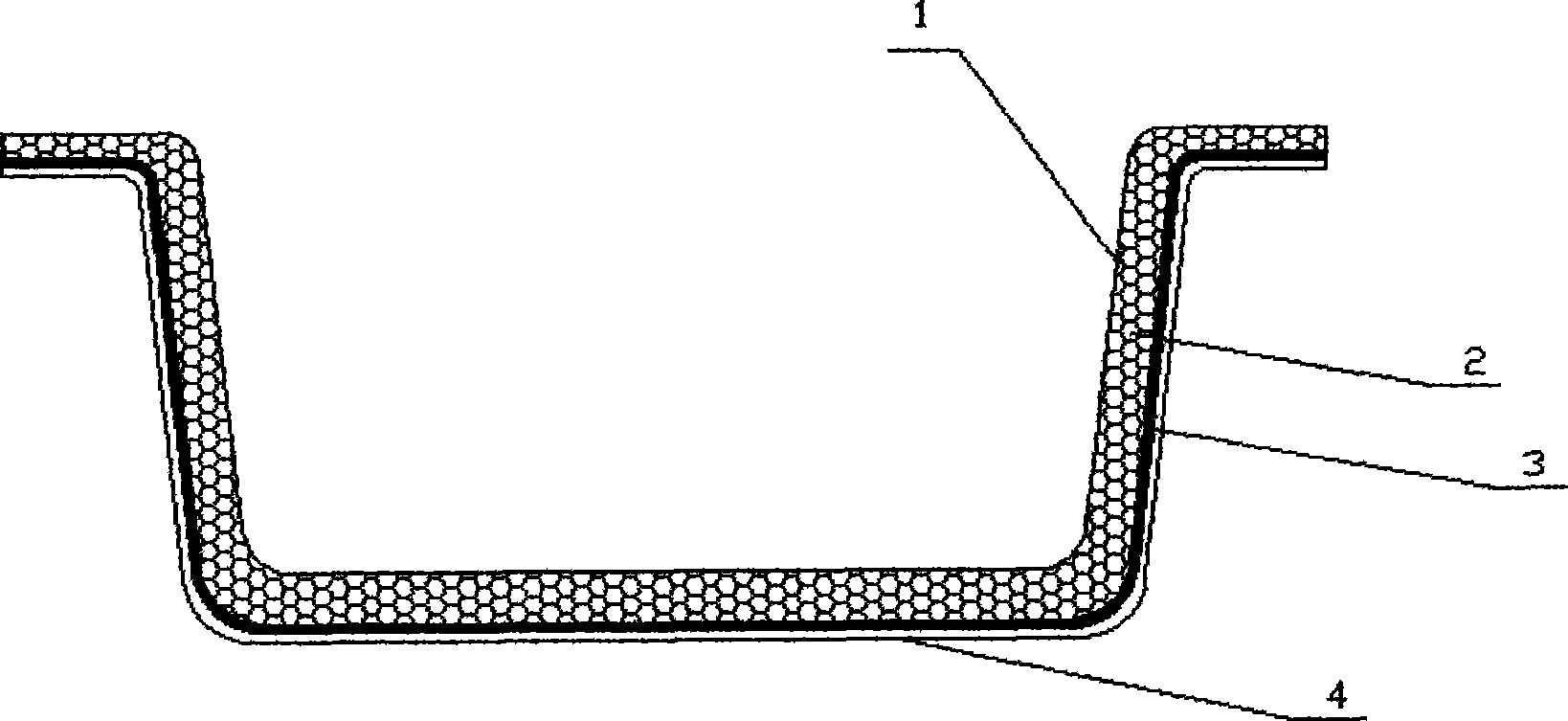

[0014] combine figure 1 A composite bathtub is mainly composed of a soft material shell 1, a shell 4, and a foamed polyurethane soft material layer 2 and a fiber bonding layer 3 as a filling layer between the soft material shell 1 and the shell 4. Its shell 4 Made of acrylic board, the fiber bonding layer 3 is arranged between the acrylic board of the bathtub shell 4 and the foamed polyurethane soft material layer 2, and the soft material shell 1 is bonded to the foamed polyurethane soft material layer 2. In this embodiment, the soft material shell 1 is made of PU artificial leather. The thickness of the PU artificial leather processed into the soft material shell 1 is 1-3 millimeters, and the thickness of the foamed polyurethane soft material layer 2 is 3-10 centimeters. The soft material housing 1 can also be made of PVC artificial leather or PU synthetic leather. The composite bathtub made by the present embodiment is provided with drain and overflow according to the prio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com