Method for decolorizing peach gum hydrolysate

A technology of hydrolyzate and peach gum, which is applied in application, food preparation, food science, etc., can solve the problems of decolorization and loss of sugar without applying peach gum, and achieve the effect of increased quantity, easy operation and short dehydration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

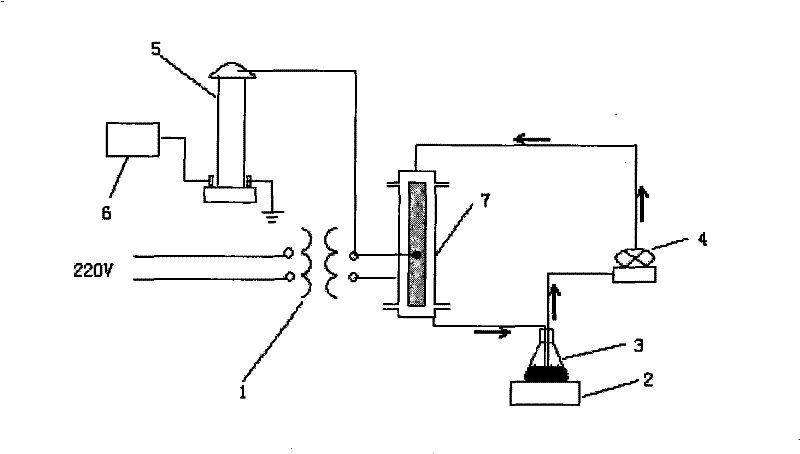

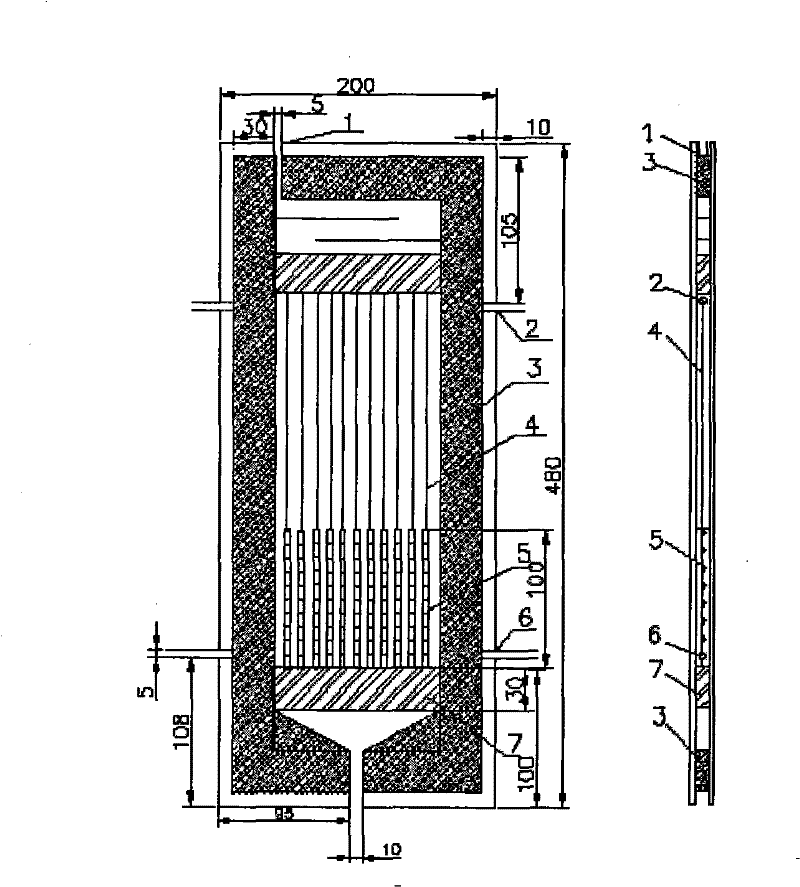

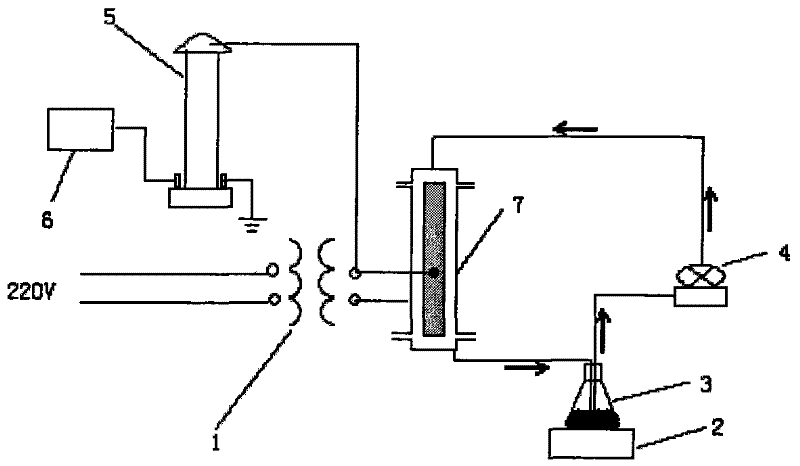

Method used

Image

Examples

Embodiment 1

[0028] Preferred embodiment 1: Clean the raw peach gum, remove the surface impurities, soak it in clean water to make it fully swell, add a certain amount of alkali reagent, boil it at 90°C for 2-3 hours, and carry out vacuum filtration , to remove impurities. Under the condition of pH=9, the peach gum hydrolyzate was decolorized by cold arc-photocatalytic technology, the cold arc working voltage was 22kv, and the initial concentration of peach gum hydrolyzate was 0.03kg / L. Titanium dioxide photocatalyst, after 19 minutes of treatment, the decolorization rate of peach gum hydrolyzate can be 76%.

Embodiment 2

[0029] Preferred embodiment 2: clean the raw peach gum to remove surface impurities, soak it in water to make it fully swell, add a certain amount of alkali reagent, cook at 95°C for 2 hours, and vacuum filter to remove Impurities. Under the condition of pH=11, the peach gum hydrolyzate was decolorized by cold arc-photocatalytic technology, the cold arc working voltage was 22kv, and the initial concentration of peach gum hydrolyzate was 0.01kg / L. Titanium dioxide is used as a photocatalyst, and the decolorization rate of the peach gum hydrolyzate is 88.3% after treatment for 19 minutes.

[0030] In addition, the decolorized peach gum hydrolyzate is placed in a vacuum dryer, and the temperature is controlled at -48°C for drying. After the concentration and dehydration rate reaches 80-90%, it is taken out and packaged to obtain the finished peach gum. .

[0031] The invention is simple, easy to operate, and applies the cold arc-photocatalysis technology to a new field; when tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com