Quasi-resonance electromagnetic heating circuit

A technology of heating circuit and electromagnetic heating device, which is applied in the direction of induction heating and induction heating control, etc., which can solve the problems of potential safety hazards, high requirements on the performance of the heating circuit of water heaters, and easy generation of scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

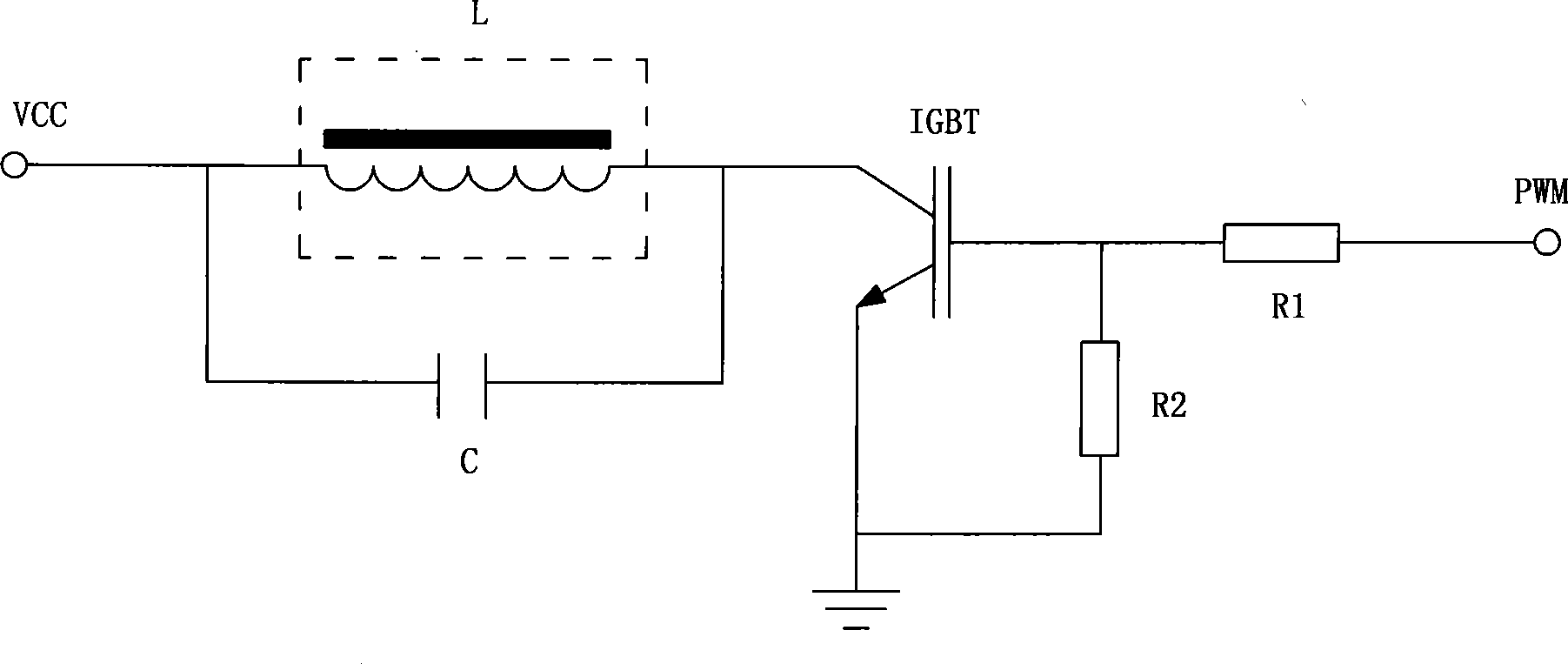

[0013] Such as figure 1 As shown, a quasi-resonant electromagnetic heating circuit includes a quasi-resonant electromagnetic heating device and a group of IGBT module IGBTs. The quasi-resonant electromagnetic heating device includes an insulating cavity, a magnetic metal heating element, a high-frequency electromagnetic coil L and a A capacitor C connected in parallel with the high-frequency electromagnetic coil L, the high-frequency electromagnetic coil L is arranged outside the insulating cavity, the magnetic metal heating element is arranged in the inner cavity of the insulating cavity, and one end of the high-frequency electromagnetic coil L is connected to a DC Power supply VCC, the other end of the high-frequency electromagnetic coil L is connected to the IGBT collector of the IGBT module, the IGBT emitter of the IGBT module is grounded, the IGBT base of the IGBT module is connected to one end of the discharge resistor R2, and the other end of the discharge resistor R2 G...

Embodiment 2

[0015] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 lies in: a quasi-resonant electromagnetic heating circuit, which includes a quasi-resonant electromagnetic heating device and two sets of IGBT modules IGBT1 and IGBT2.

[0016] With respect to the above embodiment, the other end of the buffer resistor R1 is further connected to the cathode of a reference voltage stabilizing diode, and the anode of the reference voltage stabilizing diode is grounded.

[0017] It should be noted that this circuit can be used in any electromagnetic heating device or equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com