Production apparatus for blank acceptor wax block of porous tissue chip

A technology for tissue chips and manufacturing devices, applied in sampling devices, material inspection products, biological testing and other directions, can solve problems such as through holes, burrs or cracks in wax molds, and difficulty in the test process, so as to improve work efficiency, ensure uniformity, Guaranteed production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

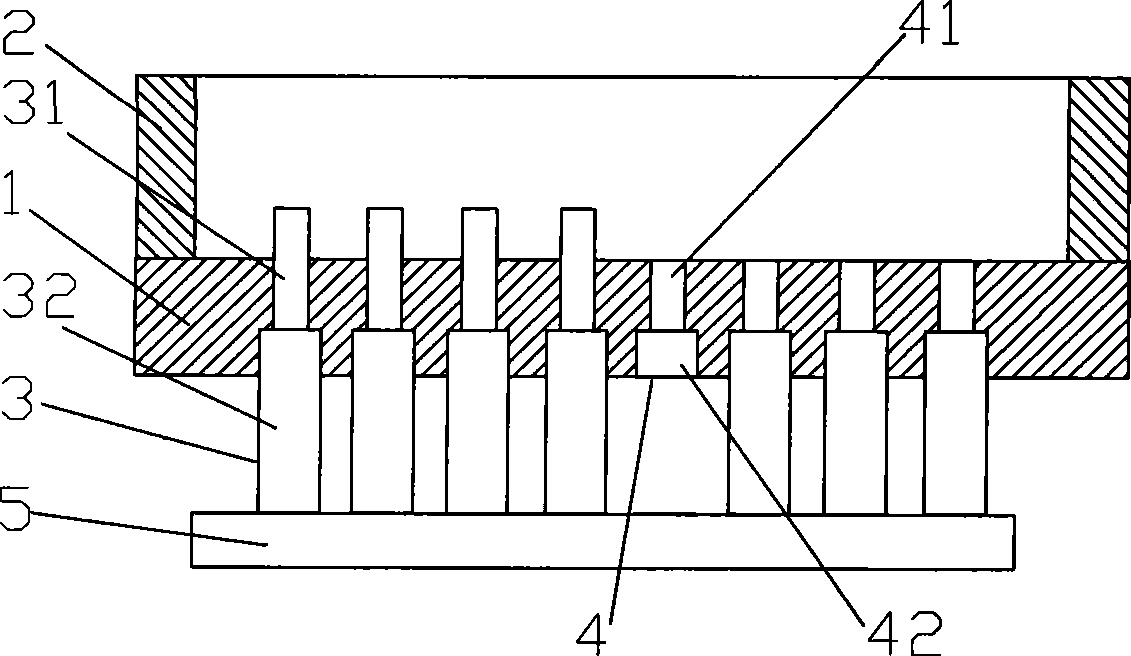

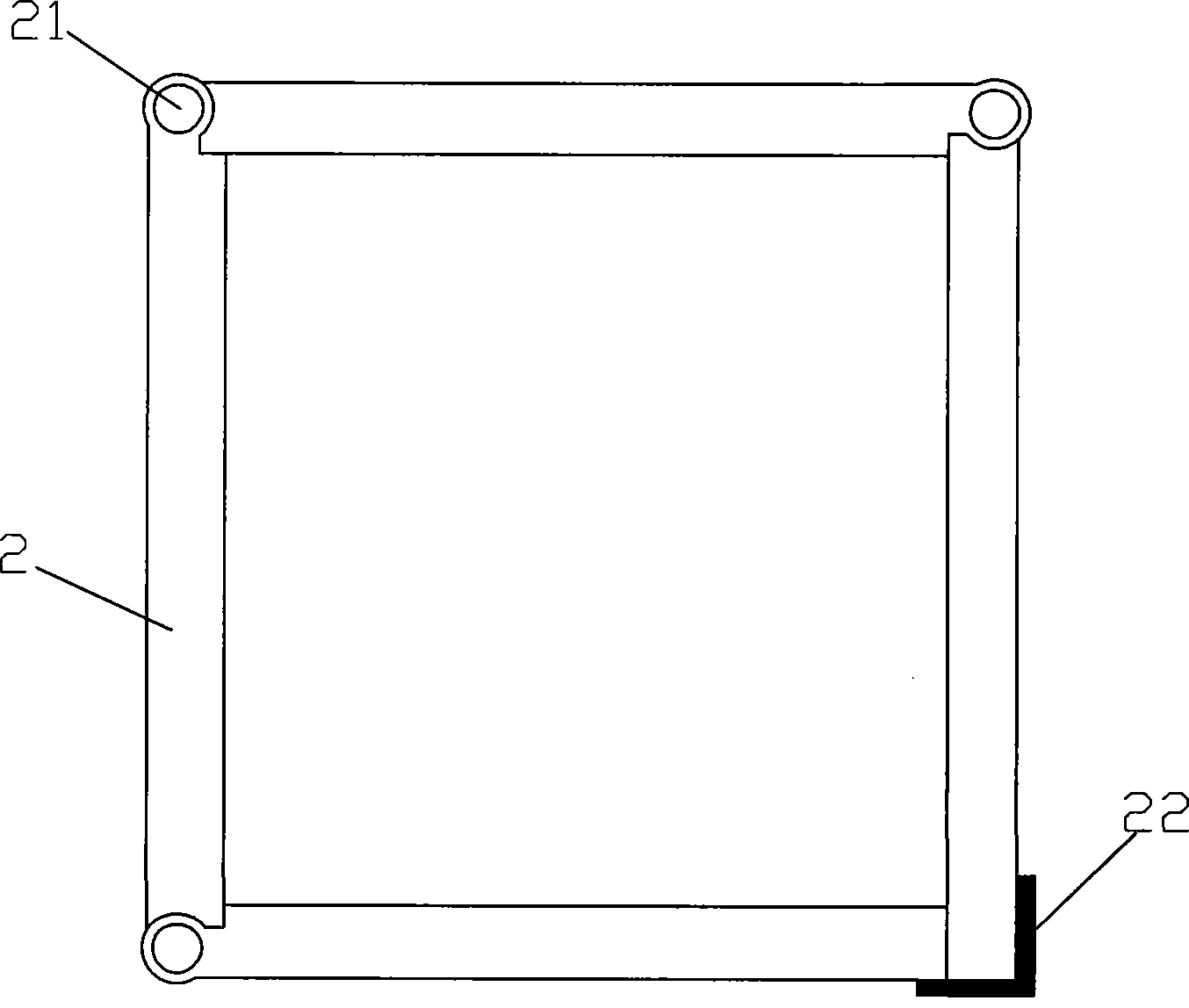

[0017] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is a schematic diagram of the rectangular cofferdam structure of the present invention, as shown in the figure: the device for making a tissue chip blank acceptor wax block with holes in this embodiment includes an orifice plate 1, a cylindrical fine needle 3 and a box together with the orifice plate 1 The detachable rectangular cofferdam 2 of the shape structure, the materials of the above components are all stainless steel, which can ensure the smoothness of the wax mold and facilitate demoulding; in this embodiment, the detachable rectangular cofferdam 2 is arranged on the upper surface of the orifice plate 1 , with the orifice plate 1 as the bottom to form a box-like structure, this structure can make use of the self-weight of the detachable rectangular cofferdam 2 to make it seal with the bonding surface of the orifice plate 1, so as to ensure the smooth molding of the wax block; o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com