Hook block assembly for well workover

A traveling block and workover technology, which is applied in the field of traveling block hooks, can solve problems such as complex structure of traveling block hooks, enlarged axial size, cumbersome use and maintenance, etc., to increase the suspension of sucker rod elevators and shorten the height , The effect of convenient workover operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

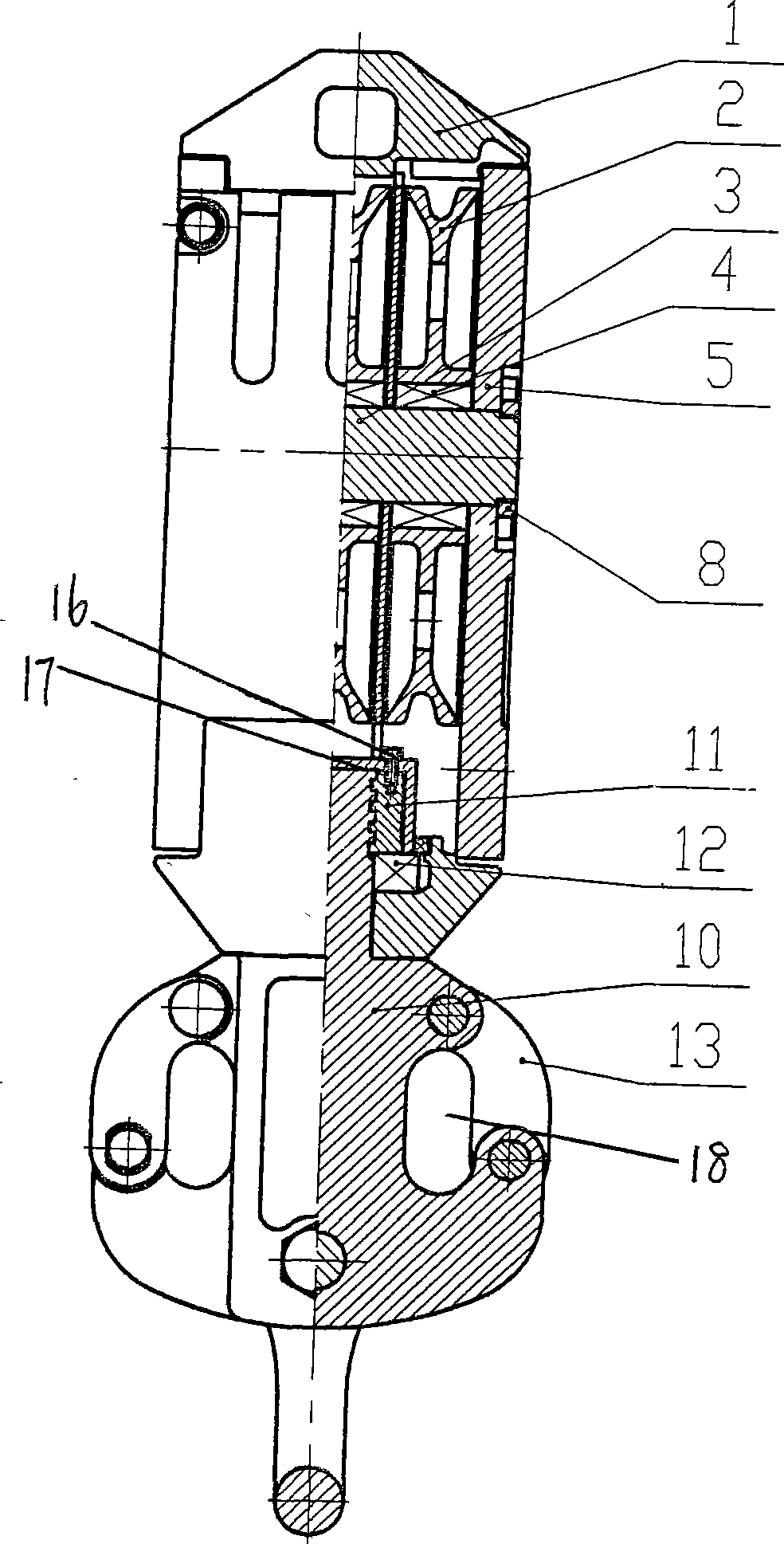

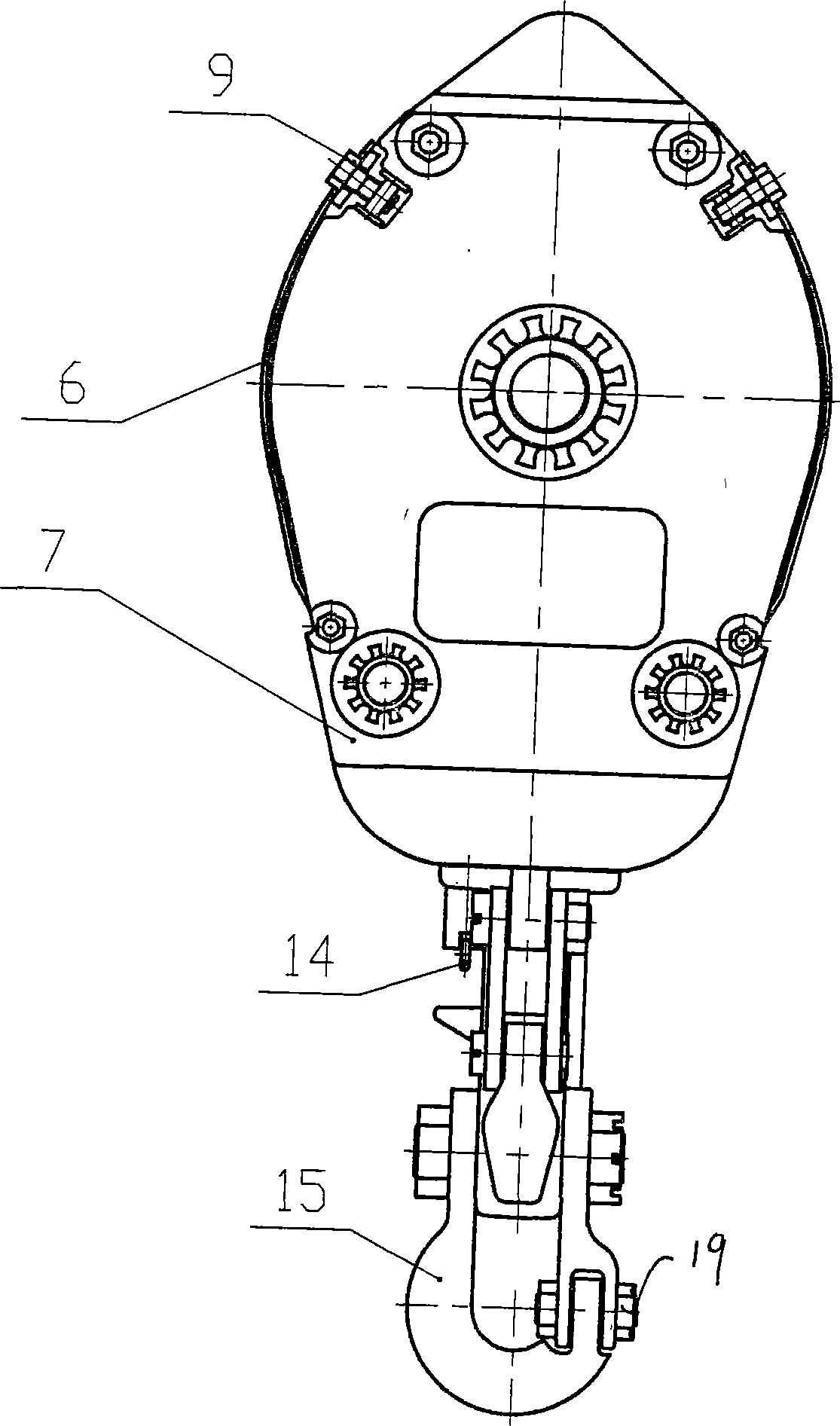

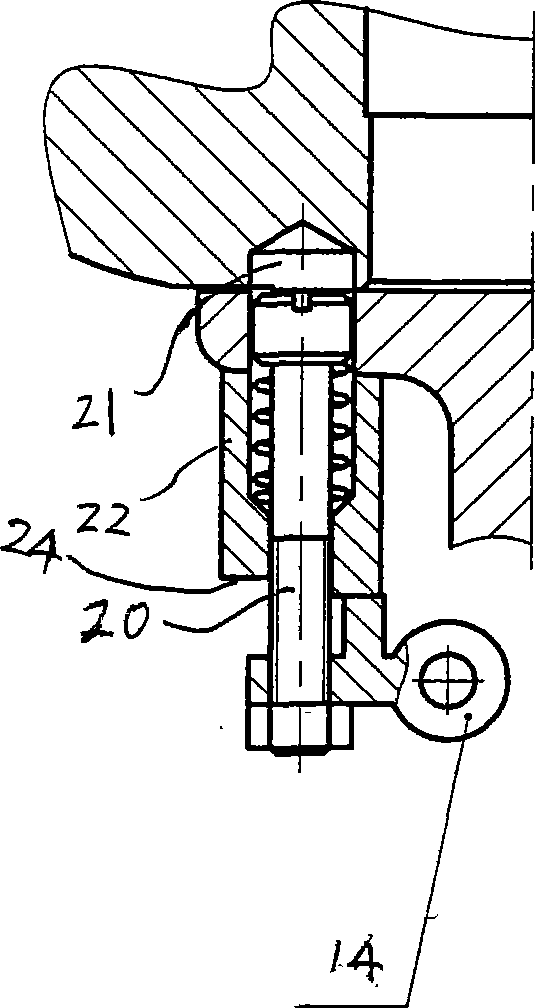

[0014] A traveling block hook for well workover, comprising a pulley box with built-in pulley 2, the pulley box includes left and right side plates 5, the left and right side plates are connected with front and rear baffles 6, the upper end of the pulley box is equipped with a beam 1, and the pulley The lower part of the box is equipped with a rotating box 7, and the upper part of the hook 10, which is installed in the bearing 12, is installed in the rotating box 7, and the outer circumference of the upper end of the hook is combined with the split nut 11 through threads, and the split nut is connected to the nut shell through the fixing screw 16. 17 connections, the hook is provided with the boom hole 18 of the suspension ring, the boom hole opening is provided with a retaining ring 13, and the sucker rod hook 15 is equipped with in the lower end of the hook.

[0015] The hook of the sucker rod includes a hook body, and the opening of the hook body is in the form of easy openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com