High-titanium blast furnace slag cooling treatment method

A treatment method and blast furnace slag technology are applied in the field of cooling treatment of high titanium type blast furnace slag, which can solve the problems of limited processing capacity, inability to process high titanium type blast furnace slag in time, unfavorable to reduce cooling cost, etc., and achieve broad application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the present invention will be further described below in conjunction with the examples, and the present invention is not limited to the scope of the examples.

[0026] Embodiment Application of the cooling treatment method of high titanium type blast furnace slag of the present invention

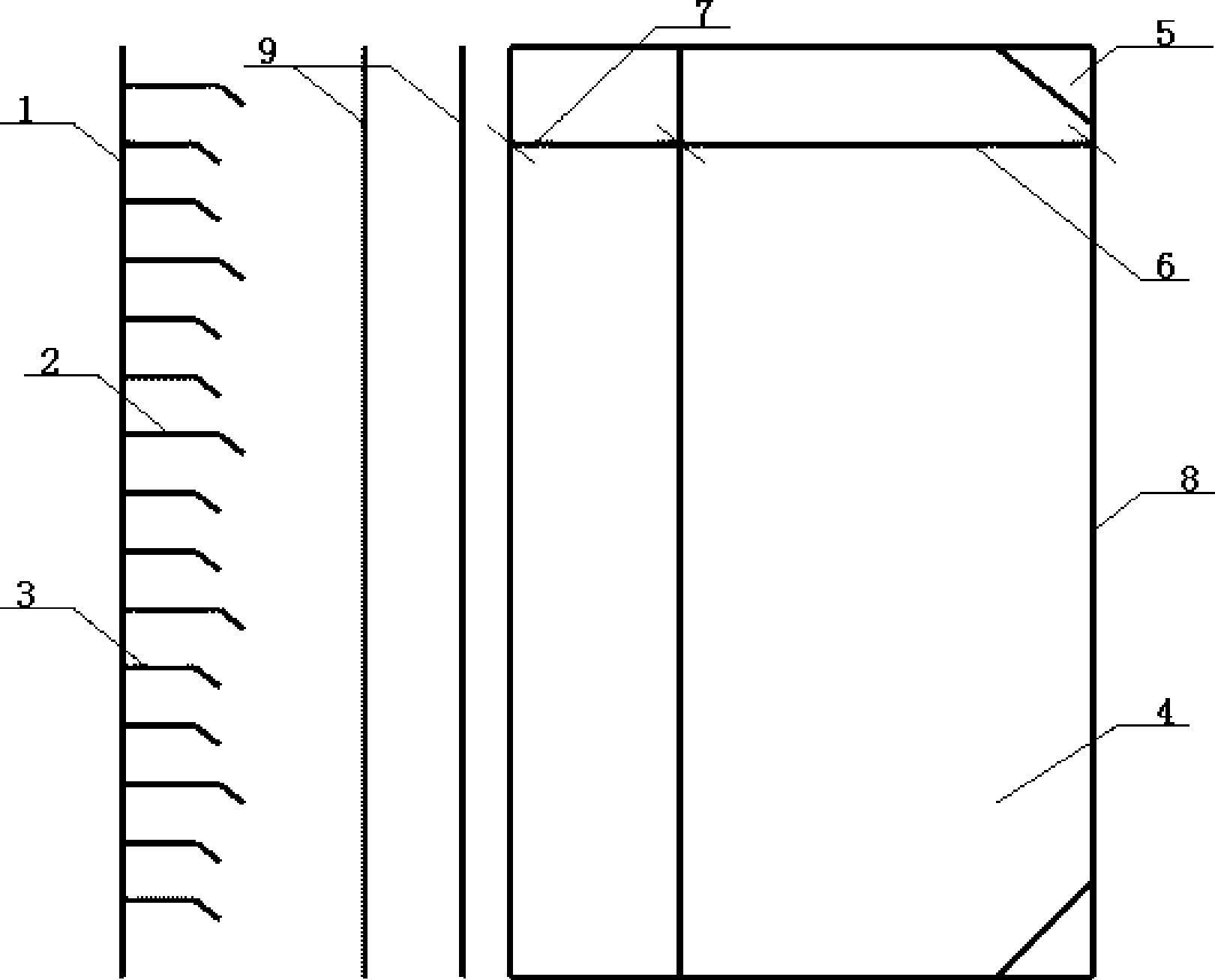

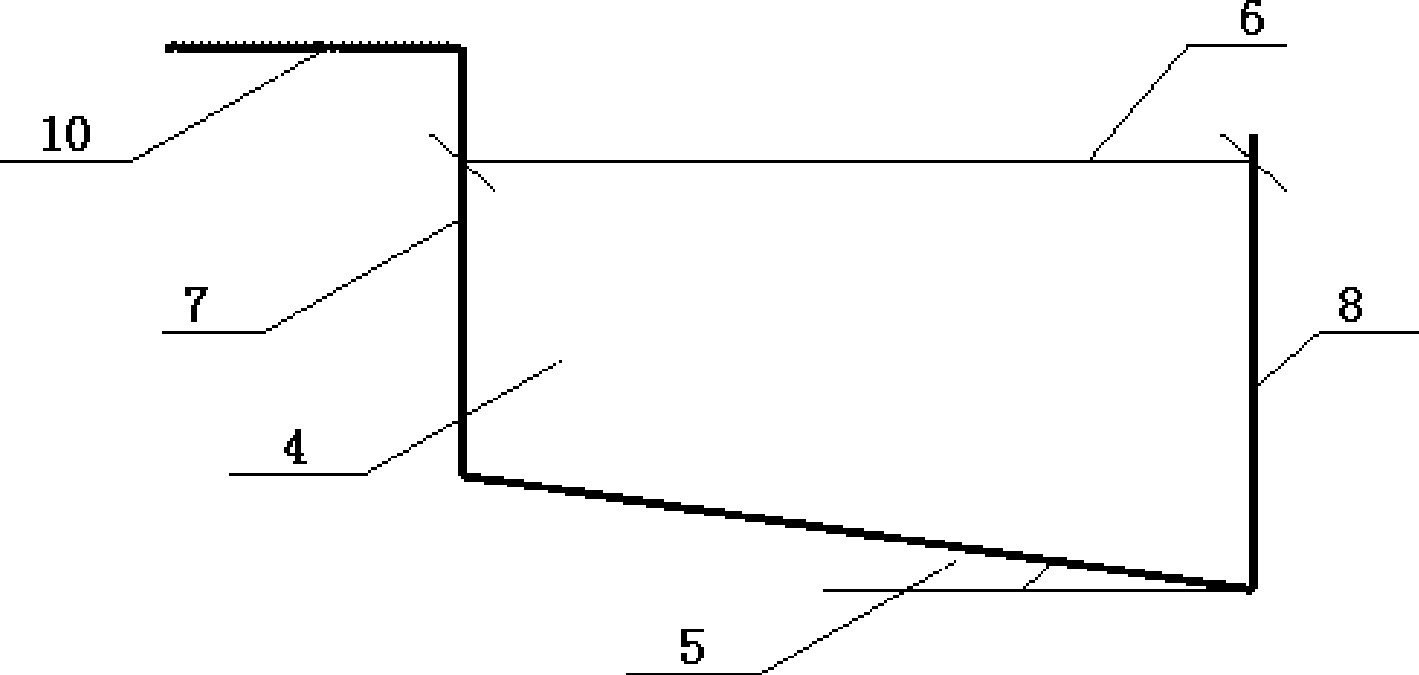

[0027] The schematic plan view of the slag pit used in the cooling treatment method of high-titanium type blast furnace slag of the present invention is shown in figure 1 , figure 1 See the top view of figure 2 , the specific operation steps of the cooling treatment method of high titanium type blast furnace slag of the present invention are as follows:

[0028] 1. Requirements for fetching water facilities

[0029] (1) According to the length of the slag pit, set the supply capacity in the slag turning platform 10 to 650m 3 Water supply pipeline 1 per hour, and a water pipe is distributed at an interval of 500mm to ensure that the cooling water pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com