Method for producing cerium-zirconium nanocomposite oxide fine particle with supercritical anti-solvent technology

A supercritical anti-solvent, nano-composite technology, used in zirconia, bulk chemical production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve cerium acetate and zirconium nitrate in absolute ethanol, control the molar ratio of cerium / zirconium to 1:10, the total concentration of cerium nitrate and zirconium nitrate is 2wt%, and use a high-pressure pump to flow it through the nozzle at a flow rate of 3ml / min. Inject into the precipitation kettle, and at the same time, inject carbon dioxide into the precipitation kettle with a pump at a flow rate of 40ml / min. The temperature of the precipitation kettle is controlled at 320K, and the pressure of the precipitation kettle is controlled at 26MPa. Under these conditions, the anti-solvent process occurs, thereby preparing the precursor nanoparticles of cerium-zirconium composite oxide.

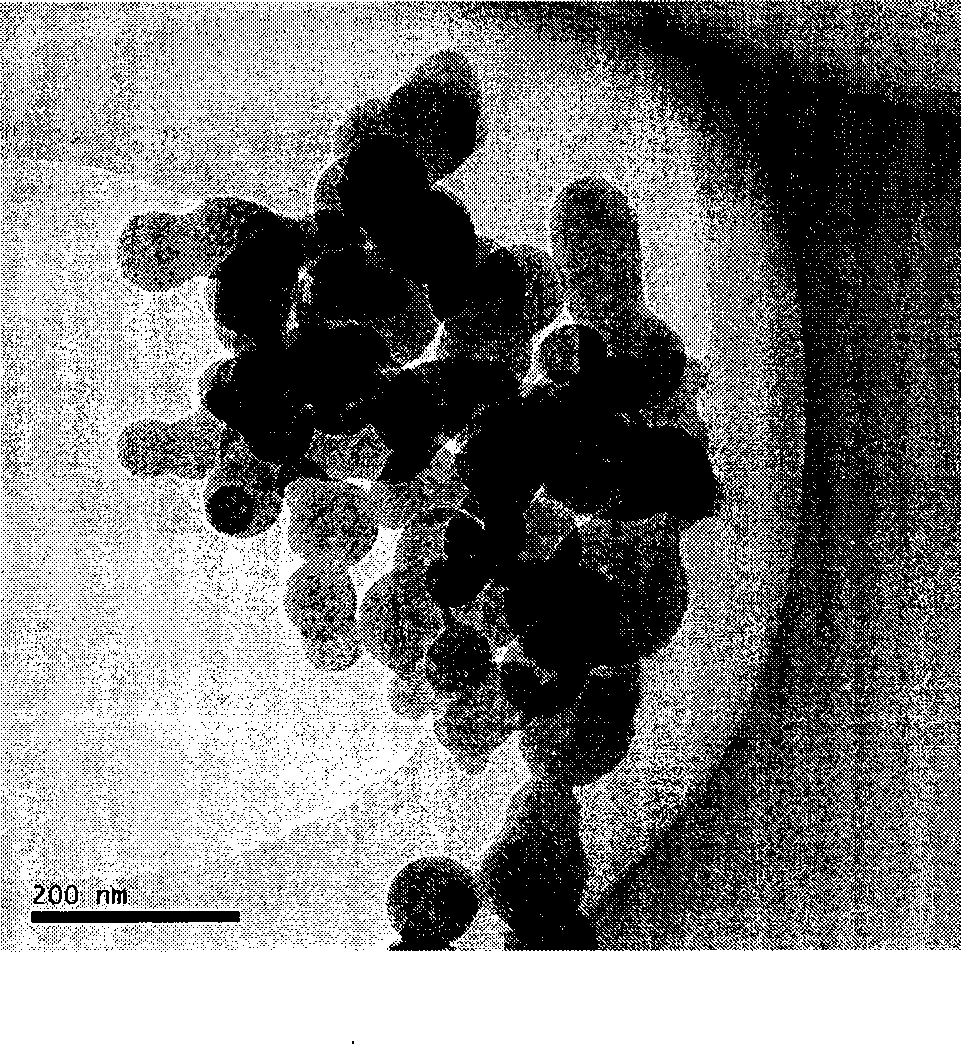

[0032] attached figure 1 The transmission electron microscope picture of the prepared cerium-zirconium composite oxide nano-precursor can be found that the average particle size range of the particle size is about 50-60nm. After firing the prepared composite oxide nano-prec...

Embodiment 2

[0034] Dissolve an appropriate amount of cerium acetylacetonate and zirconium acetylacetonate in methanol so that the molar ratio of cerium / zirconium is 3:1, the total concentration of cerium nitrate and zirconium nitrate is 3wt%, and use a plunger pump to pass through the nozzle at a flow rate of 2ml / min The solution is injected into the precipitation kettle, and at the same time, carbon dioxide is injected into the precipitation kettle with a pump at a flow rate of 30ml / min. The temperature of the precipitation kettle is controlled at 340K, and the pressure of the precipitation kettle is controlled at 40MPa. Then, a supercritical anti-solvent process occurs under the above conditions, thereby preparing a cerium-zirconium nanocomposite precursor. After the prepared nano-composite oxide precursor is calcined at 873K for 2 hours, cerium-zirconium nano-composite oxide particles can be prepared, and the particle size range is about 50-60nm. Its XRD spectrum is attached Figure 4...

Embodiment 3

[0036]The cerium acetylacetonate was dissolved in absolute ethanol, the solution concentration was 3%, the temperature of the precipitation tank was controlled at 313K, and the pressure was 35MPa, and the rest of the preparation process was the same as in Example 2. The cerium nano-precursor particles are prepared, and after being calcined at 773K for 2 hours, the average particle size of the cerium oxide oxide is 40-50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com