Liquid crystal display device, and its manufacturing method

A liquid crystal display device, liquid crystal technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as the inability to ensure the specified size of the cell gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

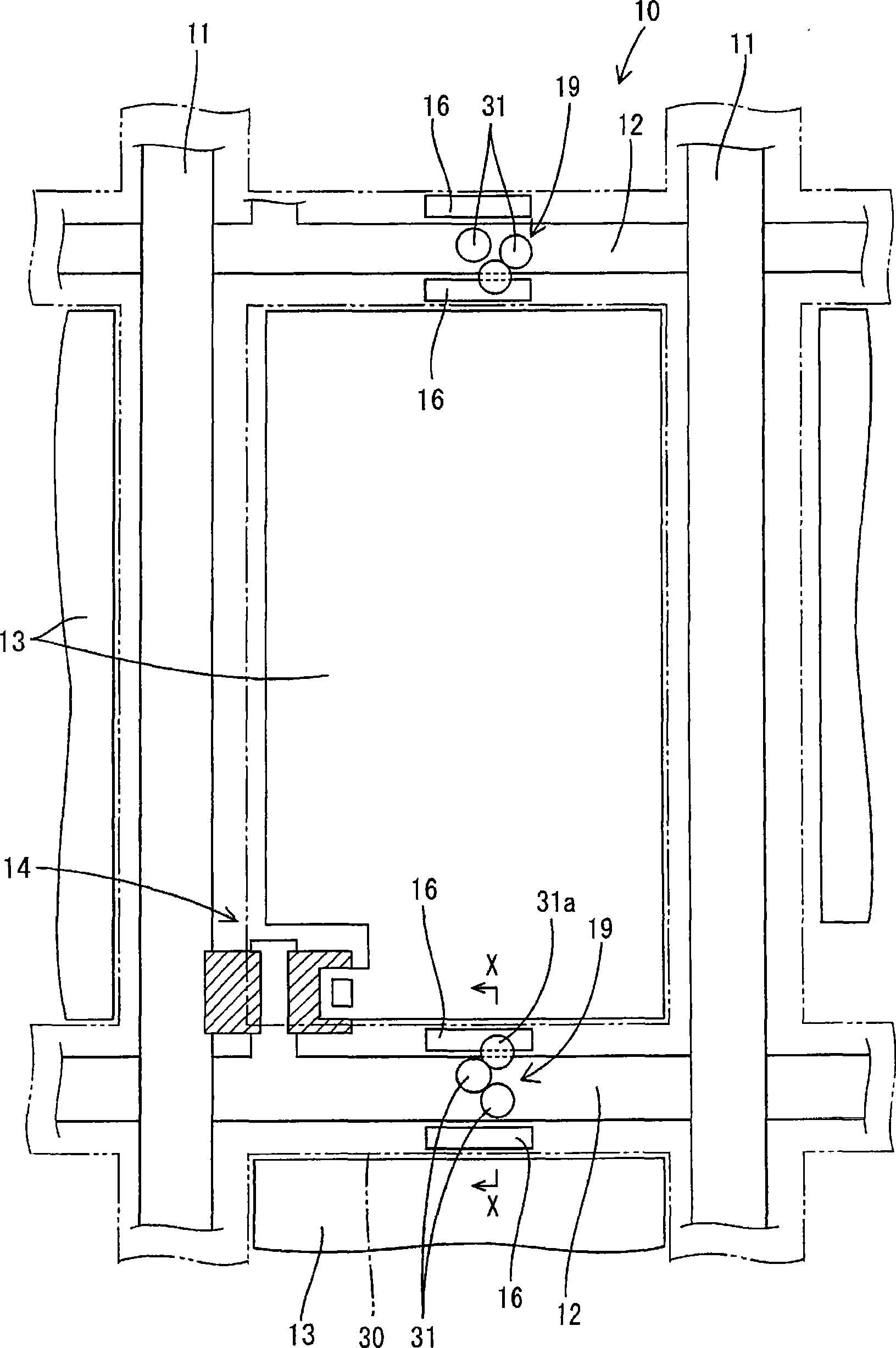

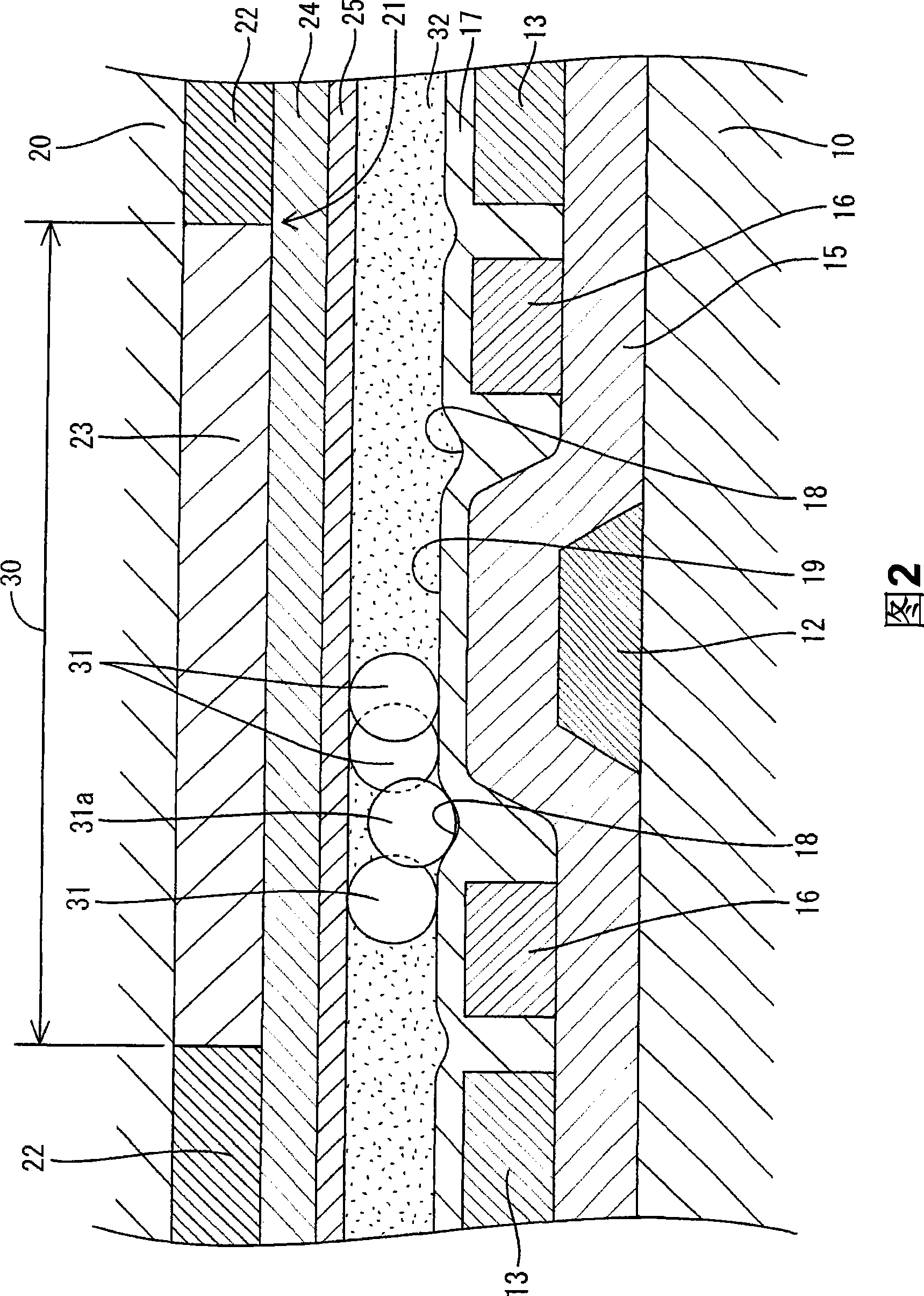

[0046] Below, refer to figure 1 and FIG. 2 illustrate Embodiment 1 of the present invention. The liquid crystal display device of the present embodiment is configured by stacking a pair of glass transparent substrates, that is, a TFT substrate 10 and a CF substrate 20 in parallel, and interposing spacer particles 31 between the two substrates 10 and 20 . While maintaining a constant distance (cell gap) between the two substrates 10 and 20 over the entire surface, liquid crystal 32 is filled in the gap between the two substrates 10 and 20 .

[0047] On the surface opposite to the TFT substrate 10 in the CF substrate 20, a color filter 21 is arranged, and the color filter 21 is arranged in a horizontal direction by a black light-shielding film 23 (black matrix) arranged in a grid shape and divided into a rectangular thin plate shape. The coloring part 22 of the three primary colors of red (R), green (G) and blue (B). In addition, a transparent thin-plate-shaped common electrod...

Embodiment approach 2

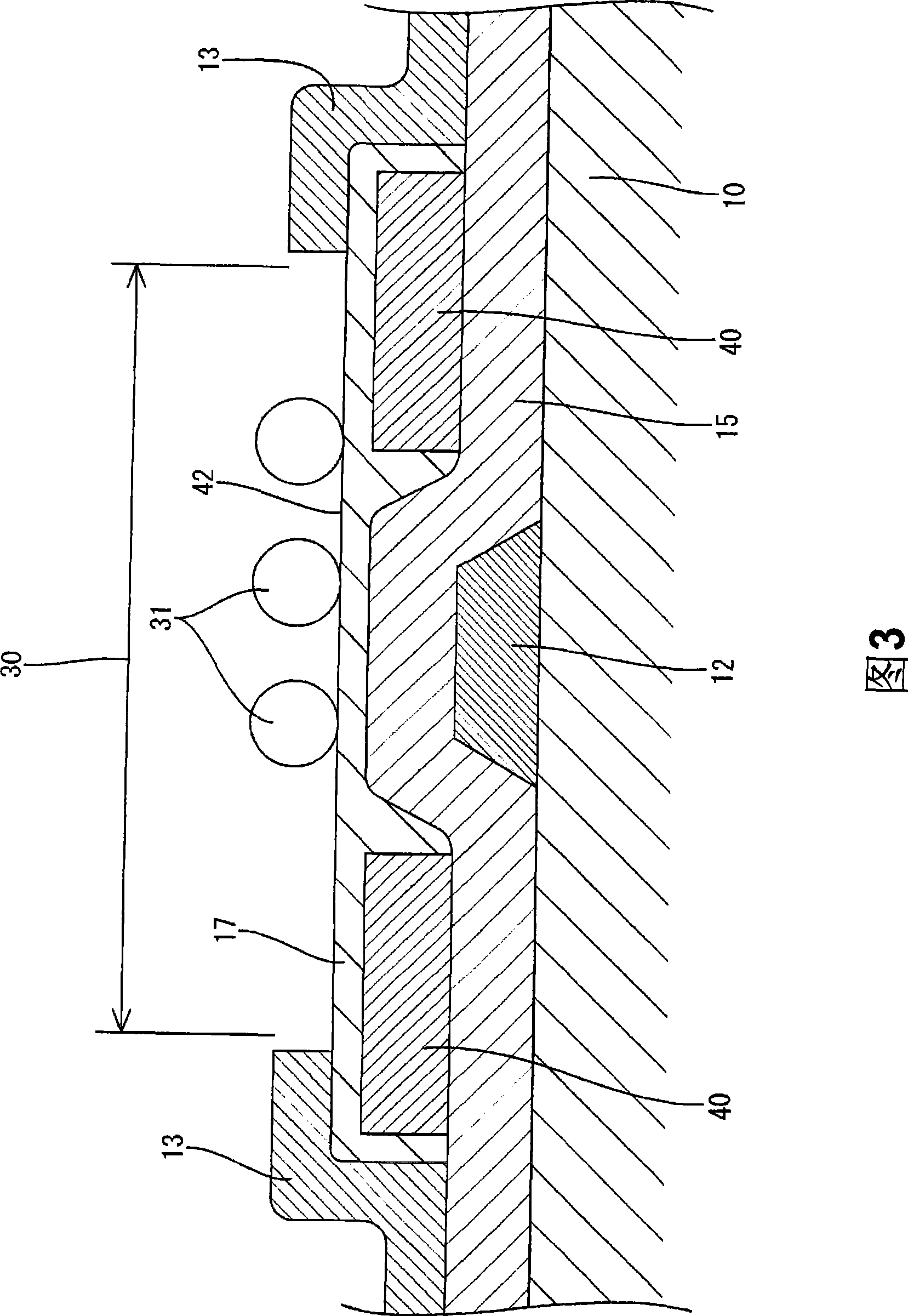

[0062] Next, a specific embodiment 2 of the present invention will be described with reference to FIG. 3 . The reinforcement layer 40 in the second embodiment is different from the first embodiment described above. The other configurations are the same as those in Embodiment 1, and therefore, the same symbols are attached to the same configurations, and descriptions of the configurations, operations, and effects are omitted.

[0063] The booster layer 40 of the second embodiment is made of the same material as the insulating layer provided on the TFT substrate 10 and the CF substrate 20 . Examples of the insulating layer include an i layer (a-Si: amorphous silicon) and an n+ layer (μC-Si: microcrystalline silicon). The width dimension of the booster layer 40 is larger than that of the booster layer 16 of Embodiment 1, and the edge portion of the booster layer 40 on the side opposite to the gate electrode line 12 protrudes outside the light shielding region 30 . Further, on t...

Embodiment approach 3

[0066] Below, refer to Figure 4 and FIG. 5 illustrate Embodiment 3 of the present invention. The third embodiment is different from the first embodiment described above in the placement surface 50 . The other configurations are the same as those of Embodiment 1 above, and therefore the same symbols are attached to the same configurations, and descriptions of the configurations, operations, and effects are omitted.

[0067] In Embodiment 3, a part of the gate electrode line 12 in the longitudinal direction is a substantially square wide portion 12W whose both side edges protrude outward. In the gate electrode line 12, the width dimension of the portion 12N other than the wide portion 12W is the same as in Embodiment 1, and narrower than the light shielding region 30, but the width dimension of the wide portion 12W is almost the same as that of the light shielding region 30 (than the width of the light shielding region 30 slightly smaller). In addition, on the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com