Microswitch

A technology of micro switch and movable mechanism, which is applied in the direction of electric switches, electrical components, circuits, etc. It can solve the problems of low rated current of the switch, slow connection and disconnection speed, unstable electric repulsion, etc., and achieve the switching function Sensitive action, quick connection and disconnection, avoiding the effect of high heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

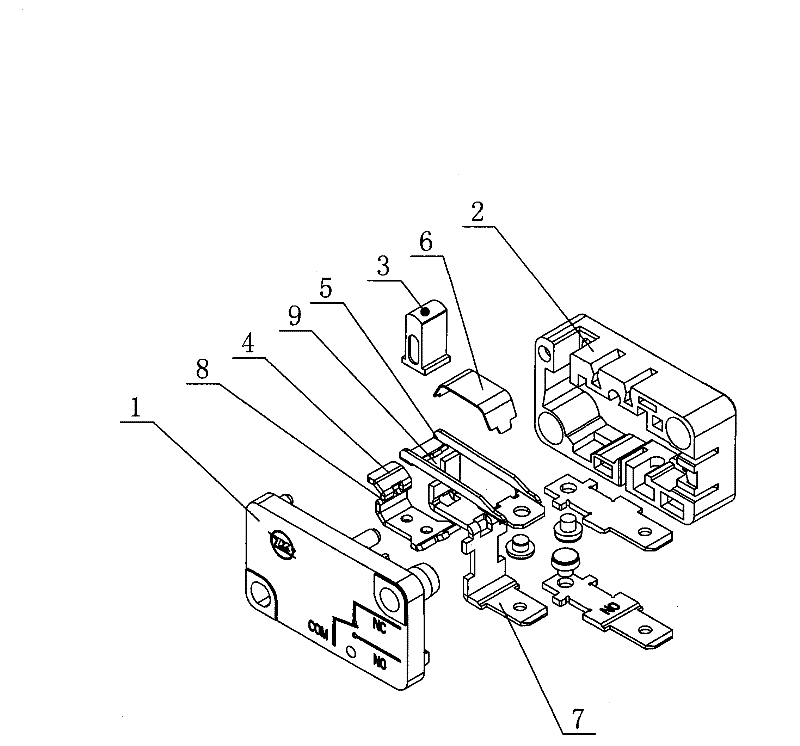

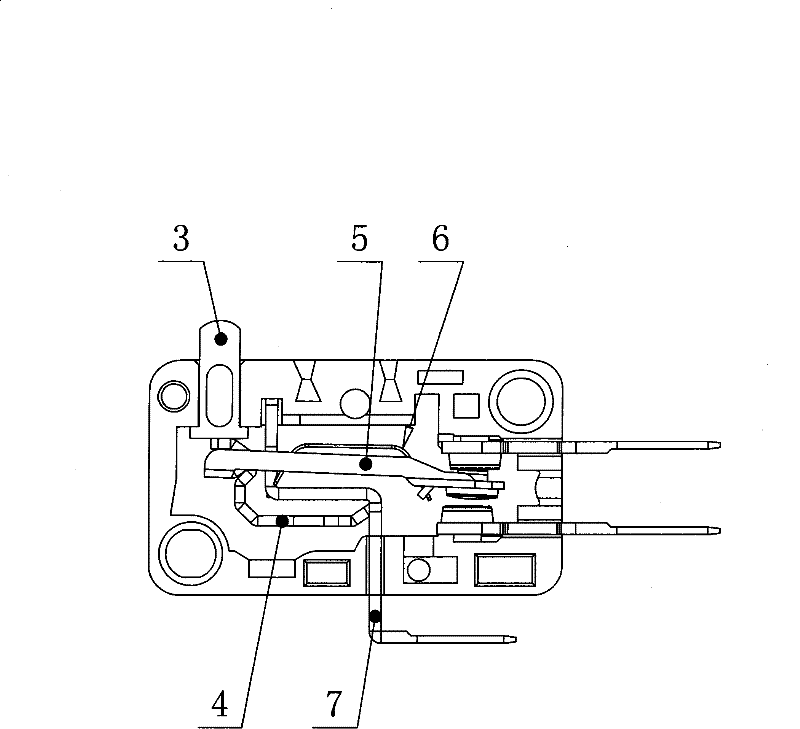

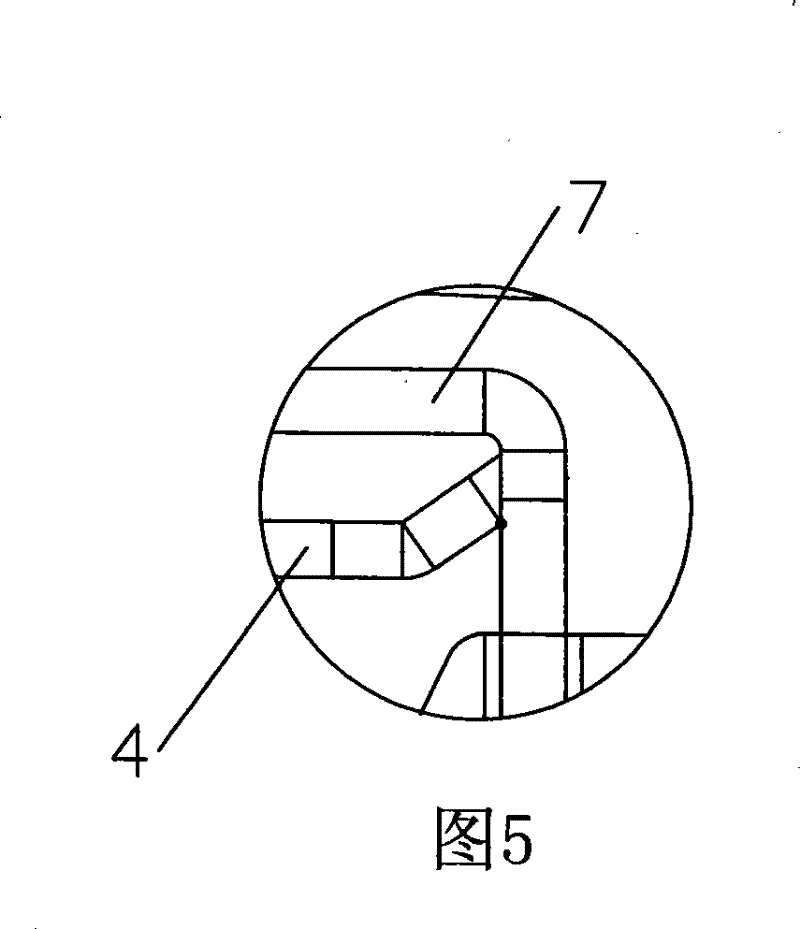

[0030] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 As shown, the micro switch provided by the present invention includes a base cover 1 and a base 2, and the base cover 1 and the base 2 are provided with a switch function conversion mechanism, and the function conversion mechanism includes a button 3, a two-bend 4, a contact bridge 5. The reed 6 and the three bends 7 and the two bends 4 are provided with a contact bridge positioning groove 8. The contact bridge positioning groove 8 is directly bent and formed by the two bends. The contact bridge 5 is provided with a mounting groove 9. The fulcrums between the bend 4 and the contact bridge 5 and between the double bend 4 and the triple bend 7 are always in line contact. In this embodiment, the end of the second bend 4 in contact with the triple bend 7 is bent u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com