Fe-containing rare-earth-base amorphous alloy

An amorphous alloy, rare earth-based technology, applied in the field of Fe-containing rare earth-based amorphous alloys, can solve problems to be further developed and improved, and achieve excellent performance, low glass transition temperature, and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

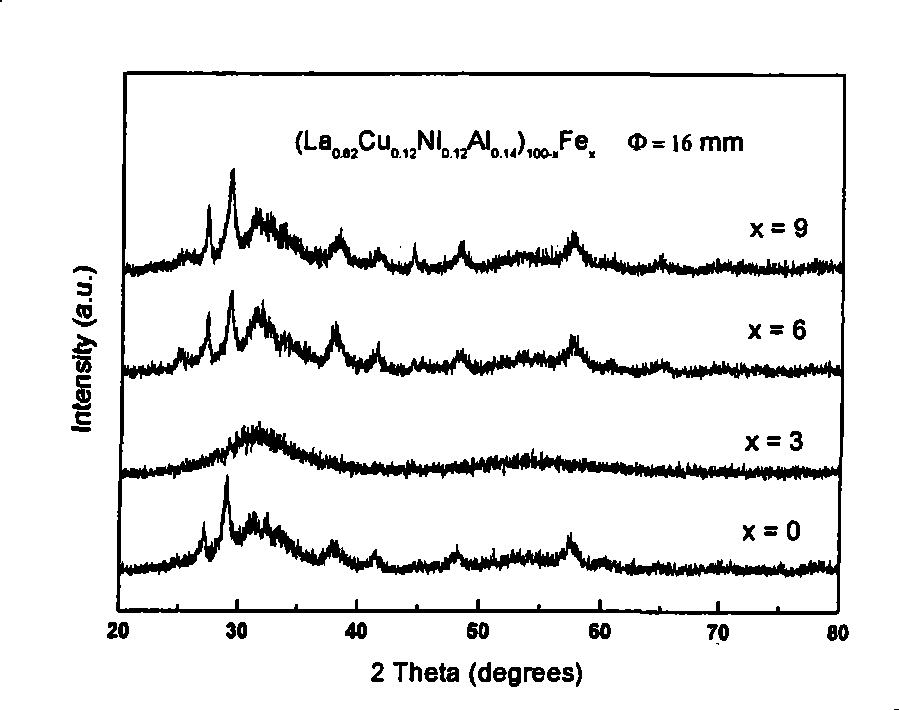

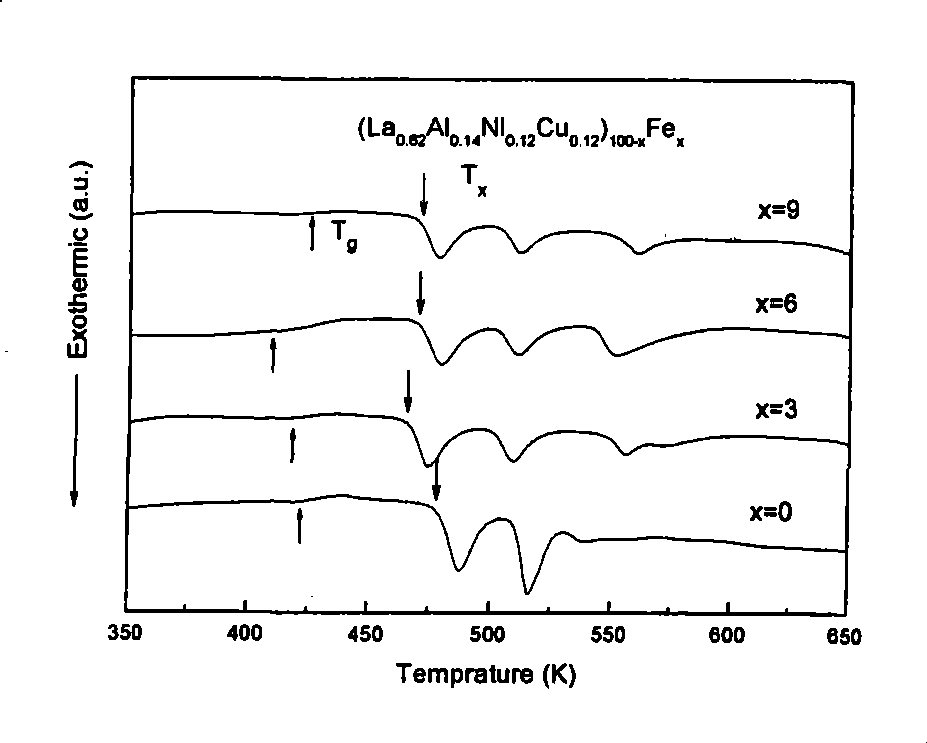

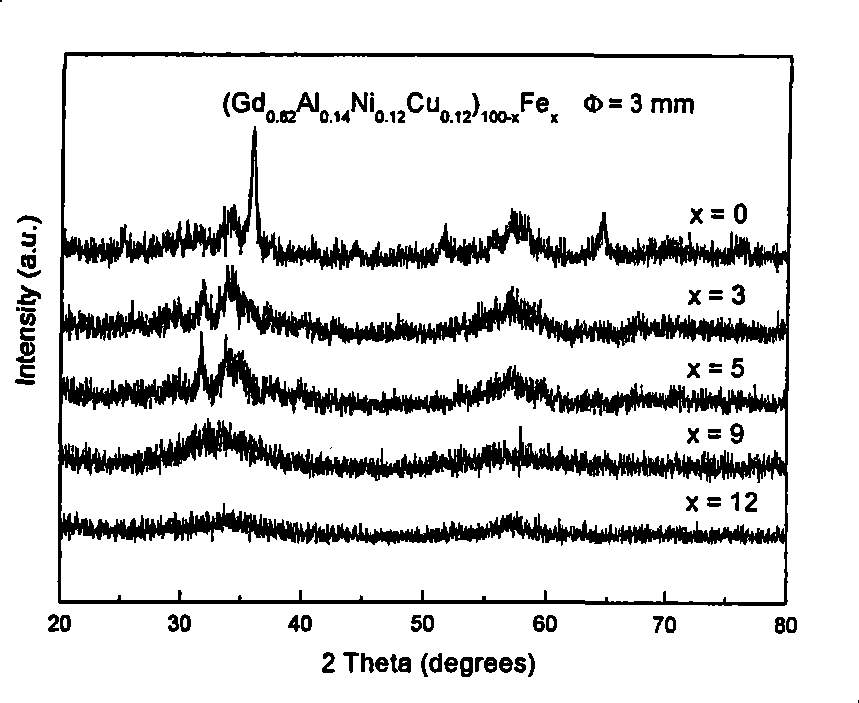

Image

Examples

Embodiment 1

[0032] Preparation (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 99 Fe 1 Amorphous Alloy Rods

[0033] Step 1: Weigh each element

[0034] Press (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 99 Fe 1 The chemical composition and atomic percentage are used to calculate the required mass and number of parts of each element and weigh them.

[0035] Step 2: preparation (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 99 Fe 1 Master Alloy

[0036] Weigh the step one (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 99 Fe 1 Put the raw materials into the vacuum smelting furnace, adjust the vacuum degree to 5*10 -3 Pa, filled with argon protective gas, adjusted to a pressure of 0.05MPa; adjusted current 50-150A, smelting temperature 1000-2000K; repeated smelting 3-4 times, cooled with the furnace, and took it out to obtain (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 99 Fe 1 master alloy.

[0037] Step 3: Prepare (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 99 Fe 1 Amorphous Alloy Rods

[0038] (La 0.62 al 0.14 Ni...

Embodiment 2

[0042] Preparation (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 98 Fe 2 Amorphous Alloy Rods

[0043] Step 1: Weigh each element

[0044] Press (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 98 Fe 2 The chemical composition and atomic percentage are used to calculate the required mass and number of parts of each element and weigh them.

[0045] Step 2: preparation (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 98 Fe 2 Master Alloy

[0046] Weigh the step one (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 98 Fe 2 Put the raw materials into the vacuum smelting furnace, adjust the vacuum degree to 5*10 -3 Pa, filled with argon protective gas, adjusted to a pressure of 0.05MPa; adjusted current 50-150A, smelting temperature 1000-2000K; repeated smelting 3-4 times, cooled with the furnace, and took it out to obtain (La 0.62 al 0.14 Ni 0.12 Cu 0.12 ) 98 Fe 2 master alloy.

[0047] Step 3: Prepare (La 0.12 al 0.14 Ni 0.12 Cu 0.12 ) 98 Fe 2 Amorphous Alloy Rods

[0048] (La 0.62 al 0.14 Ni...

Embodiment 3

[0053] Preparation (La 0.62 Al 0.14 Ni 0.12 Cu 0.12 ) 97 Fe 3 Amorphous Alloy Rods

[0054] Step 1: Weigh each element

[0055] Press (La 0.62 Al 0.14 Ni 0.12 Cu 0.12 ) 97 Fe 3 The chemical composition and atomic percentage are used to calculate the required mass and number of parts of each element and weigh them.

[0056] Step 2: preparation (La 0.62 Al 0.14 Ni 0.12 Cu 0.12 ) 97 Fe 3 Master Alloy

[0057] Weigh the step one (La 0.62 Al 0.14 Ni 0.12 Cu 0.12 ) 97 Fe 3 Put the raw materials into the vacuum smelting furnace, adjust the vacuum degree to 5*10 -3 Pa, filled with argon protective gas, adjusted to a pressure of 0.05MPa; adjusted current 50-150A, smelting temperature 1000-2000K; repeated smelting 3-4 times, cooled with the furnace, and took it out to obtain (La 0.62 Al 0.14 Ni 0.12 Cu 0.12 ) 97 Fe 3 master alloy.

[0058] Step 3: Prepare (La 0.62 Al 0.14 Ni 0.12 Cu 0.12 ) 97 Fe 3 Amorphous Alloy Rods

[0059] (La 0.62 Al 0.14 Ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com