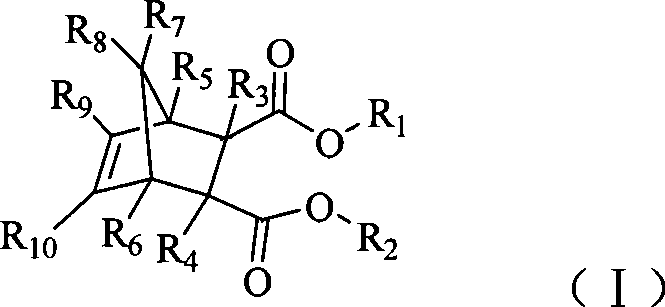

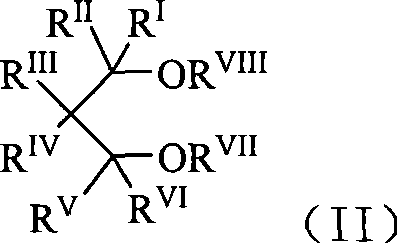

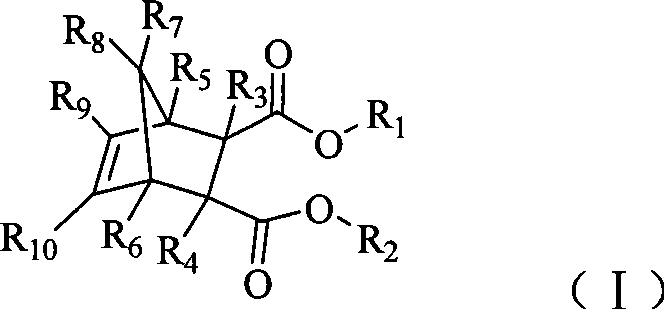

Catalyst component for olefin polymerization and catalyst thereof

A catalytic component and olefin polymerization technology, which is applied in the field of olefin polymerization catalytic components and its catalysts, can solve the problems of difficult compound synthesis and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-27

[0049] Under anhydrous and oxygen-free conditions, add TiCl 4 100ml and toluene 60ml, cool down to -20°C, add 10.0gMgCl 2 ·2.8CH 3 CH 2 OH spherical carrier (prepared according to the method of USP4399054). Rise to 0°C within 1 hour, continue to raise the temperature to 20°C within 2 hours, continue to raise the temperature to 40°C within 1 hour, add 7.4mmol of the corresponding succinate compound in Table 1 (prepared by the aforementioned method) , the temperature was raised to 100°C in 1 hour, maintained for 2 hours, and the filtrate was drained. Add TiCl 4 100ml, raised to 120°C for 1 hour, maintained for 2 hours, and drained the filtrate. Add 60 ml of anhydrous hexane, wash 5 times in a boiling state, then add 60 ml of anhydrous hexane, wash 3 times at normal temperature, and finally vacuum-dry the obtained catalytic component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com