Integral type film biological reactor

A membrane bioreactor, bioreactor technology, applied in the direction of sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of easy fiber breakage, increased cleaning difficulty, unstable water outlet, etc. To achieve the effect of prolonging the life of the membrane, reducing the amount of aeration and increasing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

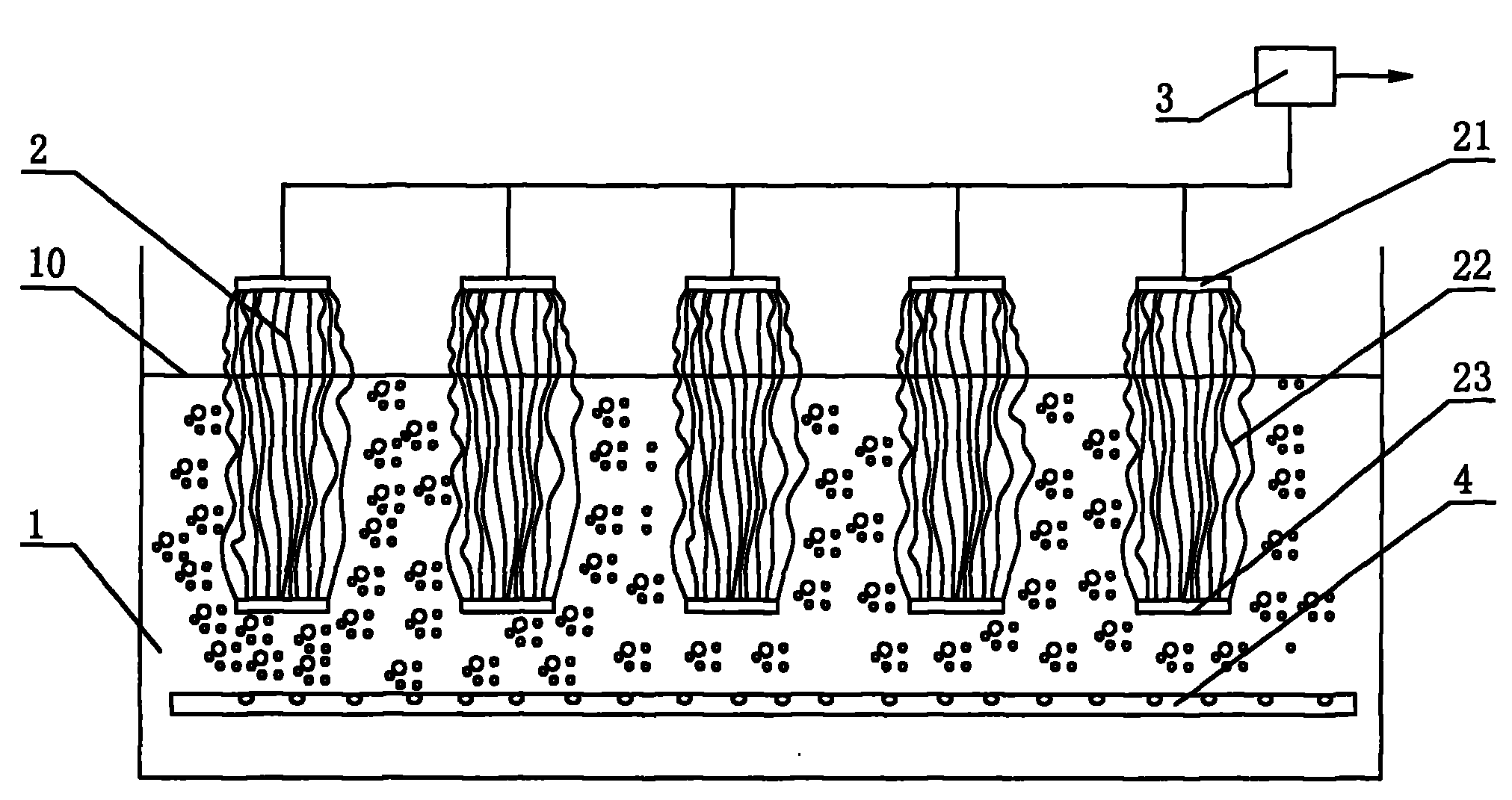

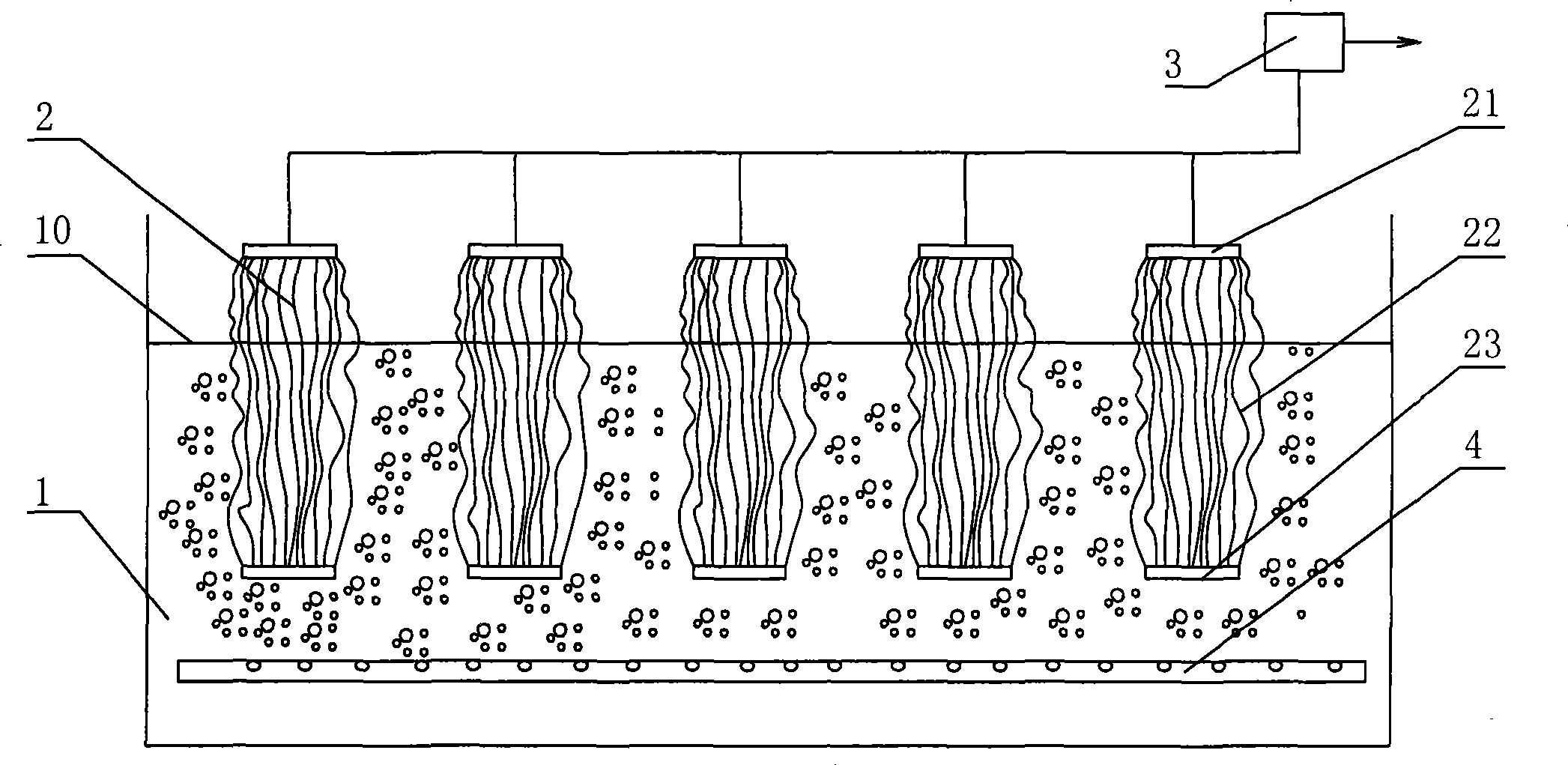

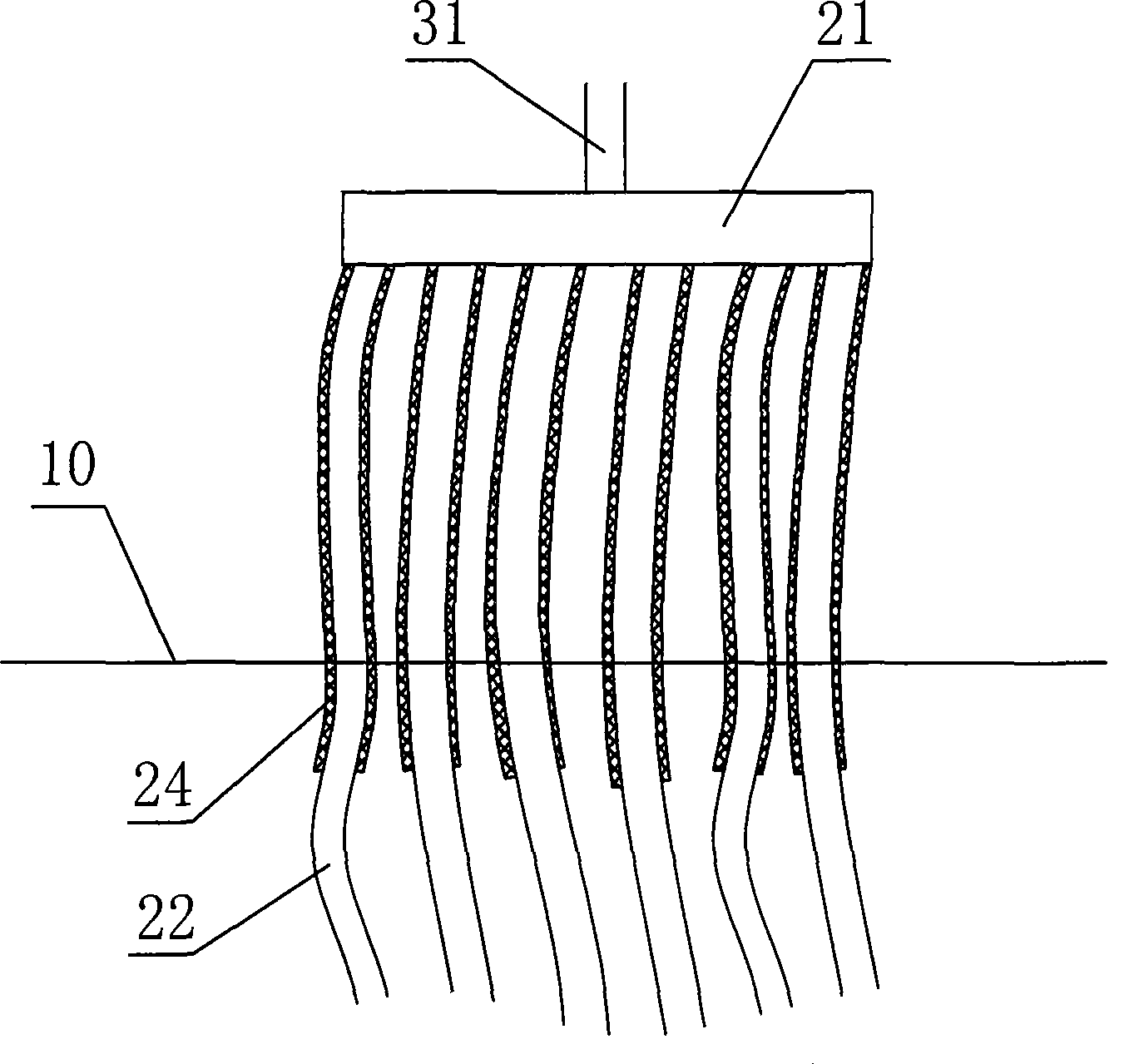

[0018] As shown in Figure 1, the integrated membrane bioreactor of the present invention includes a bioreactor 1 and a hollow fiber membrane module 2, and the hollow fiber membrane module 2 is vertically installed in the bioreactor 1, and its lower end 23 and membrane wire 22 Most of them are all submerged in water, and the suction end 21 that it links to each other with the suction pump 3 is located above the water surface 10, and a section of membrane silk near the suction end 21 just exposes the water surface like this. Since a part of the membrane filament is exposed to the air, the suction inside the hollow membrane filament will suck the air into the membrane filament, resulting in an evacuation phenomenon. For this reason, the surface part of the membrane filament exposed to the air must be sealed, and the present invention is provided with a sealing layer outside the membrane filament, and the sealing layer needs to extend below the water surface 10 .

[0019] As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com