Method for preparing nano grade iron oxide red

An iron oxide red, nano-scale technology, applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of difficult to control the particle size and shape of iron oxide red, long cycle, high production cost, improve land utilization, The effect of short production cycle and compact structure

Inactive Publication Date: 2011-01-05

ZHEJIANG GENKY CHEM

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention aims at the current problems such as difficulty in controlling the particle size and shape of iron oxide red, poor dispersibility, impure hue, etc., as well as the disadvantages of high production cost, high equipment requirements, complex process, long cycle and low yield, and provides a particle size The preparation method of nano-scale iron oxide red with uniform diameter distribution, good dispersion and pure hue has the advantages of low production cost, no special requirements for equipment, simple process and short cycle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

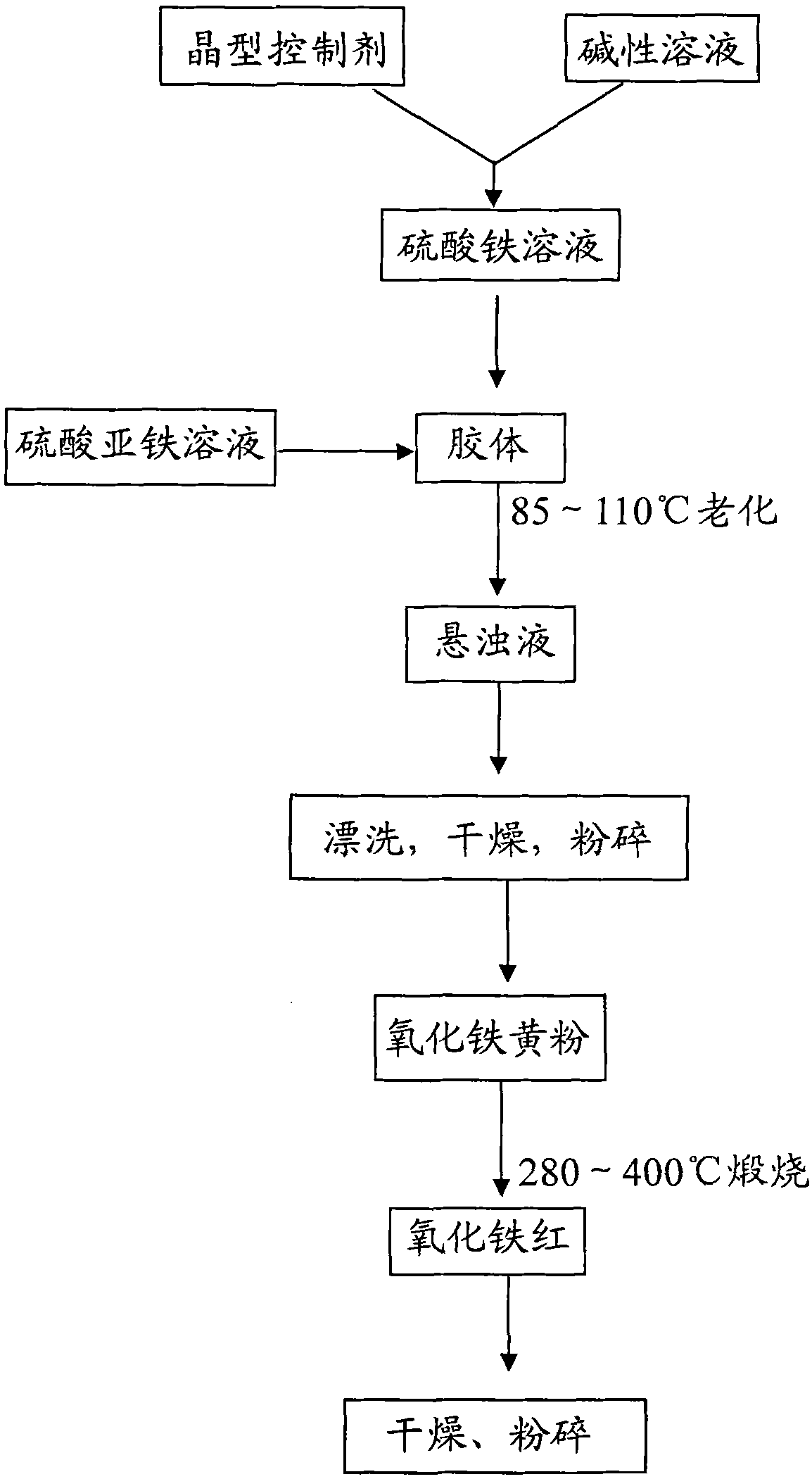

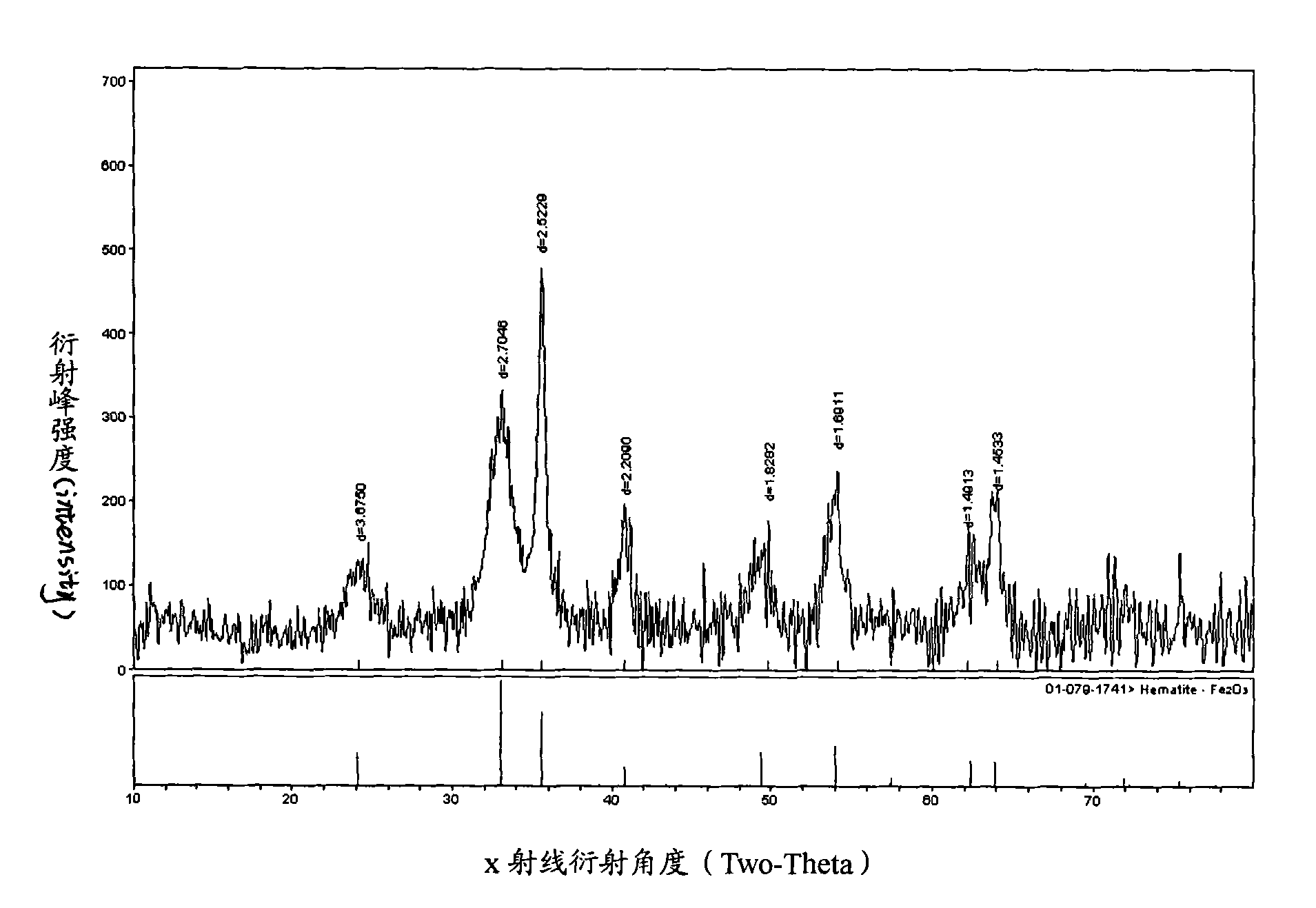

The invention discloses a nanoscale iron oxide red preparation method, comprising the steps as follows: firstly, alkaline material is dissolved in water so that alkaline solution is prepared; secondly, the alkaline solution is mixed with crystalline control agent, and a certain amount of the mixed solution is collected and added into ferric sulfate solution at the temperature of 30 to 50 DEG C until the pH value is 8 to 10, and then is heated to 65 to 75 DEG C for reaction, so that colloid is produced and seed crystal is prepared; thirdly, the pH value is adjusted to 2 to 5, and a certain amount of ferrous sulfate solution is added and heated to 85 to 110 DEG C, and takes aging reaction for 3 to 9 hours; fourthly, after filtering, the filter cake is rinsed with water, dried and crushed, so that transparent iron oxide powder is obtained; and finally, the iron oxide powder is calcined at the temperature of 280 to 400 DEG C, dried and crushed, so transparent nanoscale iron oxide red is obtained. The prepared transparent iron oxide red has the advantages of uniform particle-size distribution, pure color phase, good dispersity, simple preparation process, strong controllability, short production cycle and high efficiency, and has no pollution to the environment.

Description

A kind of preparation method of nanoscale iron oxide red technical field The invention relates to the field of production methods of iron oxide red, in particular to a preparation method of nanoscale iron oxide red. Background technique Nano science and technology is a new technology that was born and emerged in the late 1980s. Its basic connotation refers to understanding and transforming nature in the range of nanometer size (10-9-10-7m), and creating New substances, as well as transforming existing substances to have new properties. Nanomaterials have basic characteristics such as quantum size effect, small size effect, surface effect and macroscopic quantum tunneling effect. These basic characteristics make nanomaterials have many potential physical and chemical properties different from conventional materials, thus causing people to develop and utilize nanomaterials A strong interest in the material. Nano-iron oxide is a large class of nano-powder materials researc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G49/06

Inventor 陈祥龙梁峰陈莹陈翔麟

Owner ZHEJIANG GENKY CHEM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com