Catalyst for direct synthesis of arene by synthesis gas and production method and use thereof

A technology for synthesizing aromatic hydrocarbons and catalysts, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low aromatic hydrocarbon selectivity, limitation of fluctuations, etc., and achieve high aromatic hydrocarbon content, moderate acidity, and aromatic structure. good chemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

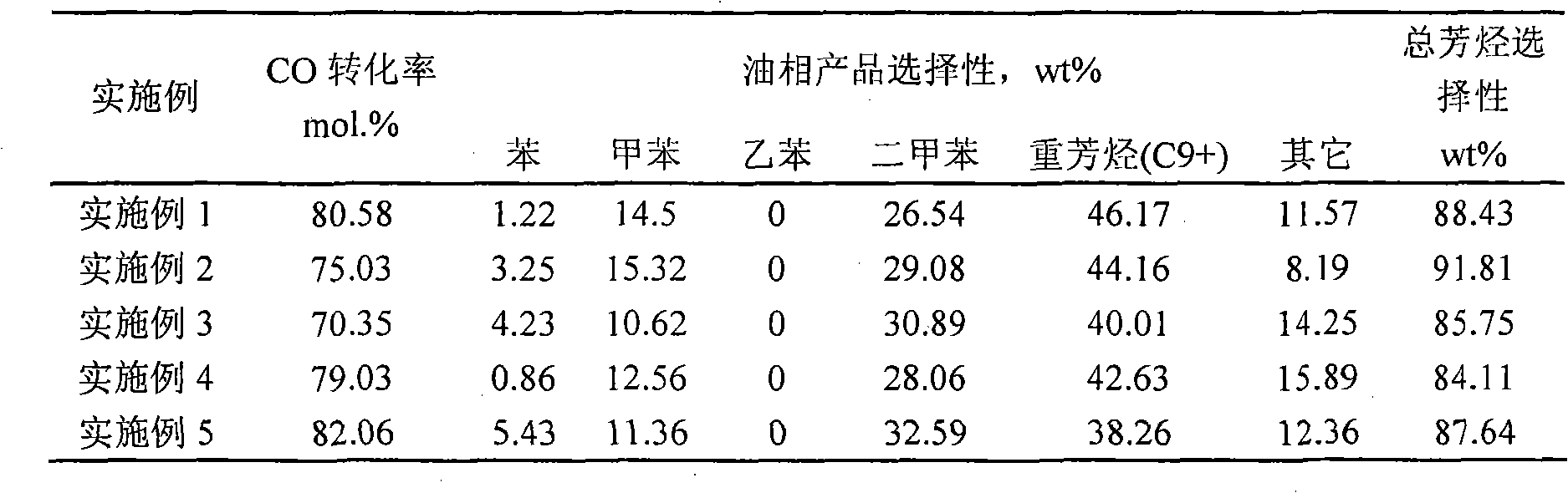

Examples

Embodiment 1

[0023] Methanol synthesis catalyst (DC207 produced by Linqu Daxiang Fine Chemical Co., Ltd.), methanol dehydration catalyst (γ-Al 2 o 3 ) were broken to 20-30 mesh respectively, according to DC207 / γ-Al 2 o 3 The volume ratio is 1:1 and mixed to form a catalyst.

[0024] The catalyst for the two-stage synthesis of aromatics is prepared in the following manner:

[0025] (1) The NKF-5 molecular sieve produced by Nankai University Catalyst Factory is exchanged with hydrochloric acid to become hydrogen molecular sieve H NKF-5;

[0026] (2) aluminum phosphate molecular sieve is carried out by the method shown in CN1132781C, concrete process:

[0027] In a 100ml beaker, successively add 2.042 grams of aluminum isopropoxide, 1.153 grams of phosphoric acid (85%), 1.360 grams of rhodamine B, 0.451 grams of diethylamine, 40 grams of water, and 26 grams of ethanol, mix well, and stir at room temperature After 24 hours, a relatively uniform sol was formed. Put the above sol into a po...

Embodiment 2

[0034] Methanol synthesis catalyst (DC207 produced by Linqu Daxiang Fine Chemical Co., Ltd.), methanol dehydration catalyst (γ-Al 2 o 3 ) were broken to 40-60 mesh respectively, according to DC207 / γ-Al 2 o3 The volume ratio is 2:1 and mixed to form a catalyst.

[0035] The catalyst for the two-stage synthesis of aromatics is prepared in the following manner:

[0036] (1) The NKF-5 molecular sieve produced by Nankai University Catalyst Factory is exchanged with hydrochloric acid to become hydrogen molecular sieve H NKF-5;

[0037] (2) aluminum phosphate molecular sieve is carried out by the method shown in CN1132781C, concrete process:

[0038] In a 100ml beaker, successively add 3.065 grams of aluminum isopropoxide, 1.736 grams of phosphoric acid (85%), 2.505 grams of rhodamine B, 0.678 grams of diethylamine, 60 grams of water, and 45 grams of ethanol, mix well, and stir at room temperature After 48 hours, a relatively uniform sol was formed. Put the above sol into a poly...

Embodiment 3

[0045] Methanol synthesis catalyst (DC207 produced by Linqu Daxiang Fine Chemical Co., Ltd.), methanol dehydration catalyst (γ-Al 2 o 3 ) were broken to 30-40 mesh respectively, according to DC207 / γ-Al 2 o 3 Mixed at a volume ratio of 5:1 to form a catalyst.

[0046] The catalyst for the two-stage synthesis of aromatics is prepared in the following manner:

[0047] (1) The NKF-5 molecular sieve produced by Nankai University Catalyst Factory is exchanged with hydrochloric acid to become hydrogen molecular sieve H NKF-5;

[0048] (2) aluminum phosphate molecular sieve is carried out by the method shown in CN1132781C, concrete process:

[0049] In a 100ml beaker, successively add 4.084 grams of aluminum isopropoxide, 2.289 grams of phosphoric acid (85%), 3.664 grams of rhodamine B, 0.995 grams of diethylamine, 146 grams of water, and 65 grams of ethanol, mix well, and stir at room temperature After 50 hours, a relatively uniform sol was formed. Put the above sol into a poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com