Automatic experiment system for bridge type crane

An overhead crane and experimental system technology, applied in educational appliances, instruments, teaching models, etc., can solve the problems of high labor intensity, high skill requirements for crane operators, and inability to achieve safe operation of the crane system, and achieve convenient data processing. , The effect of large measurement range and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

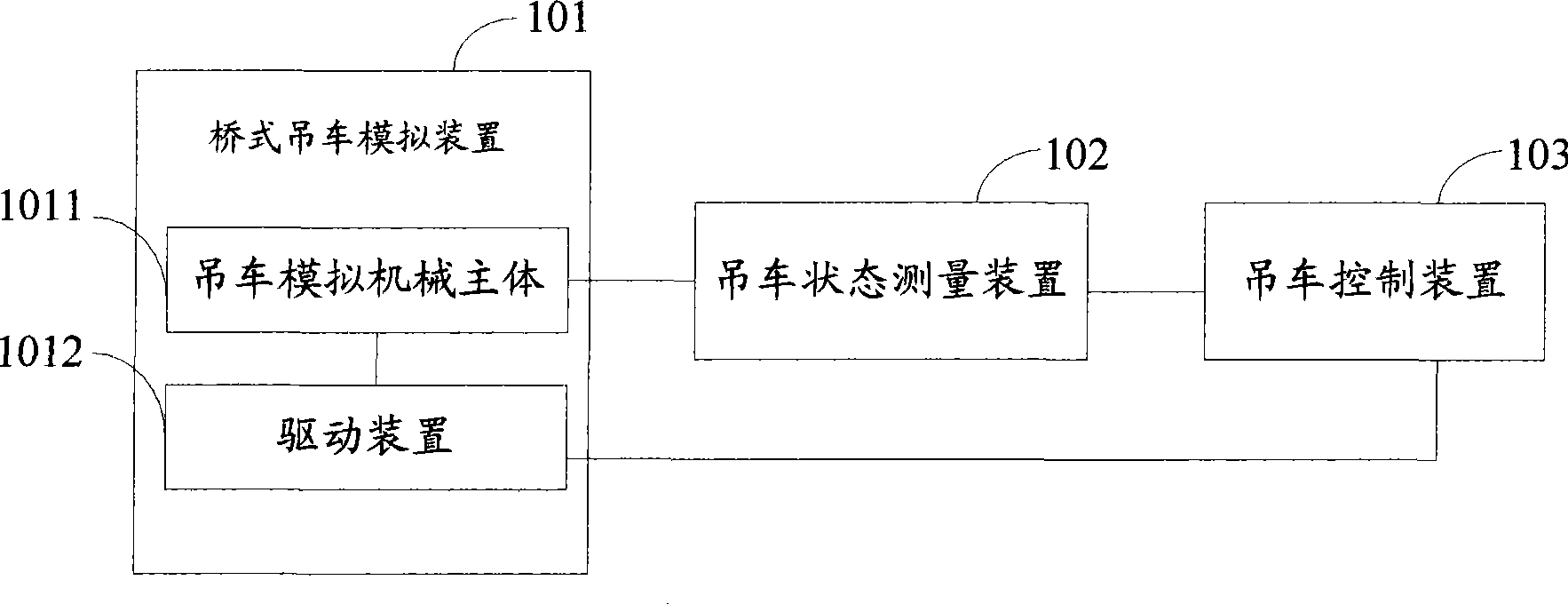

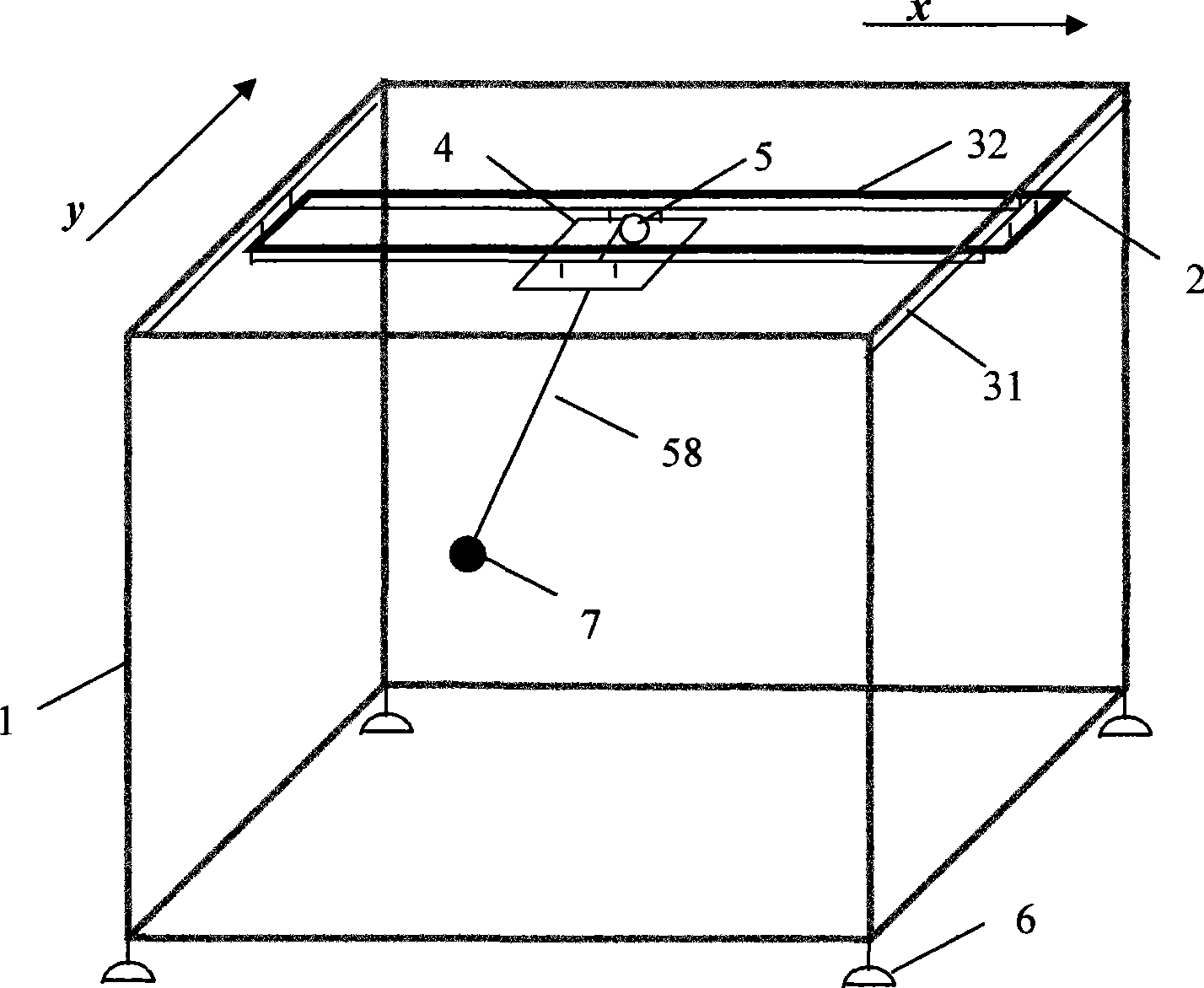

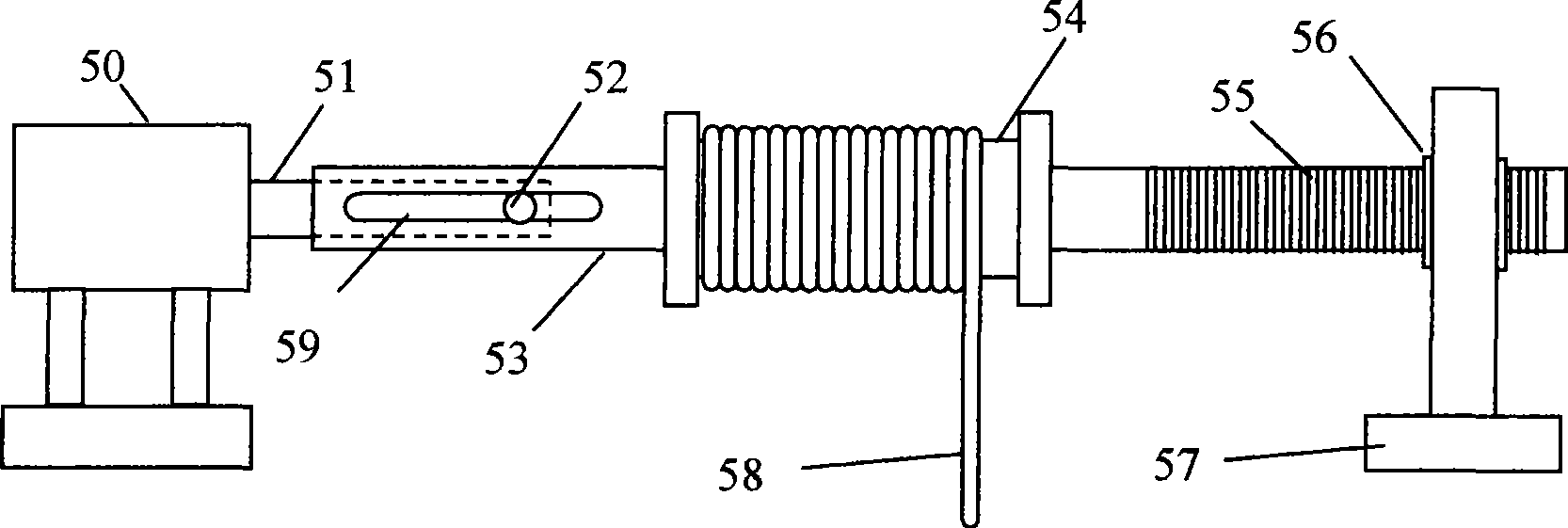

[0032]In recent years, many scholars in the field of automation at home and abroad have carried out a lot of research on the overhead crane system, and proposed a variety of control methods, trying to realize the safe and efficient transportation of the overhead crane. However, most of these control methods use linearized or simplified system models, and the actual crane system is a strongly nonlinear system, and there are still interference factors such as friction and wind during operation, so if applied to the actual system However, the reliability of these methods is difficult to guarantee. In order to better study the dynamic characteristics of overhead cranes, verify the control effects of various control methods, and further propose m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com