Underground mine natural ventilation equipment

A natural ventilation and underground mine technology, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the problems of high electric fire, reduce miners' working strength, and high equipment maintenance costs, and achieve the improvement of physical health, The effect of reducing maintenance workload and reducing infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

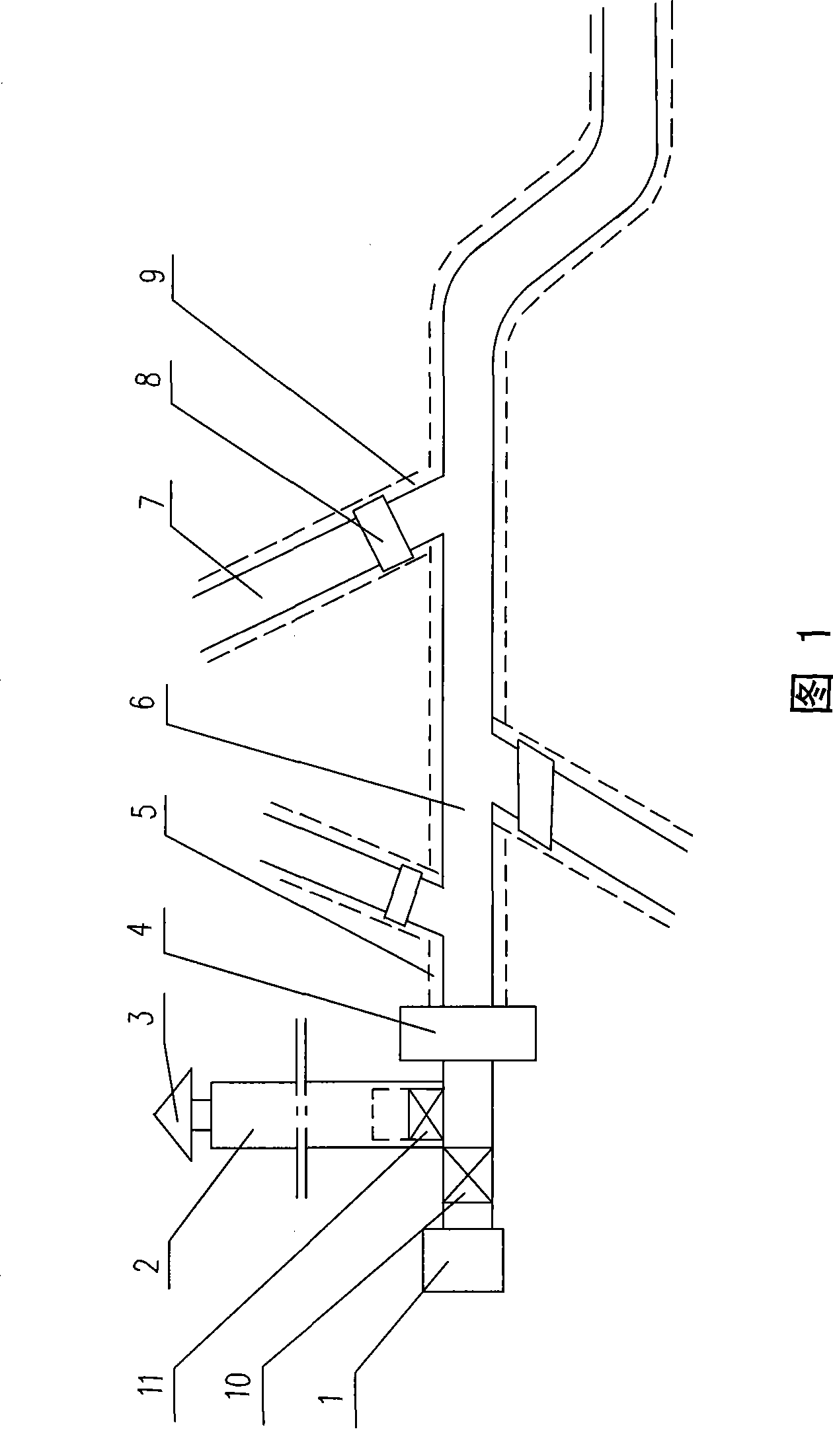

Image

Examples

Embodiment

[0036] A jade mine originally used mechanical forced ventilation equipment. Because the ventilation effect is not good enough, it affects the health of the staff and the economic benefits of the mining enterprise. After adopting the natural ventilation equipment for underground mines of the present invention, the problem of air quality near the tunnel surface in the tunnel is completely solved, and the air quality in the tunnel is close to the air quality outside the mine. Until the air is fresher than before, except for the presence of dust near the face of the blasting operation, the air at other times is clean. The dust generated by the blasting operation can be sucked away by the ventilation equipment in a very short time, thus avoiding the harm to the health of workers and various safety hazards caused by poor ventilation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com