Novel production process of high-purity 5' nucleotide

A nucleotide, high-purity technology, applied in microorganisms, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of inability to desalinate, reduce yield, and complex process, and achieve fast permeation flow rate, operation and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

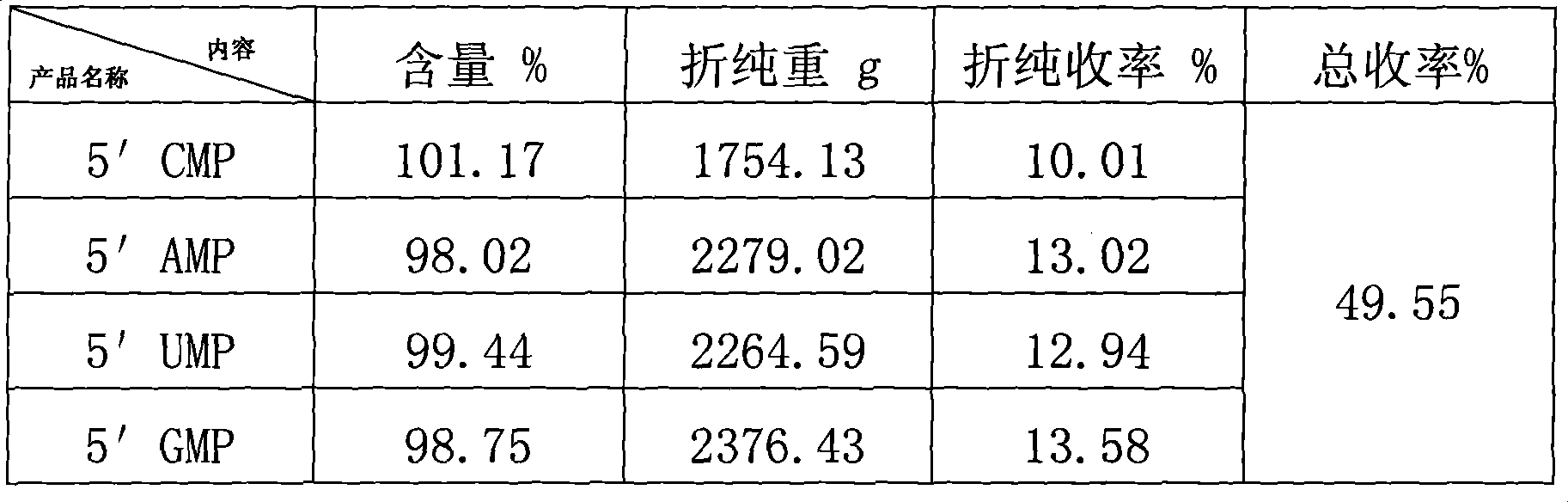

[0027] Produce high-purity 5' nucleotides according to the following new production process of 5' nucleotides, including concentrating nuclease P1 to degrade ribonucleic acid (RNA) into a 5' nucleotide solution, which is subjected to vibrating sieve, ultrafiltration, resin adsorption, Stepwise elution, collection, nanofiltration, concentration, decolorization, crystallization, and drying to obtain four kinds of pure nucleotides 5'CMP, 5'AMP, 5'UMP, and 5'GMP with a content ≥ 98%.

[0028] nuclease P 1 : Penicillium citrinum strain M-71 was cultivated in liquid deep ventilation, and nuclease P was obtained after 30 hours of cultivation 1 , Enzyme activity 1200 units / ml. Concentrated Nuclease P by Nanofiltration 1 , the nuclease P 1 Concentrate through a 300 Dalton nanofiltration membrane into an enzyme solution greater than 7500 units / ml for use;

[0029] Concentrated Nuclease P 1 Carry out the degradation of ribonucleic acid: get pure 17.5kg RNA and make 2.5% solution, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com