Double-plastid rectilinear vibration crusher

A linear vibration and crusher technology, applied in the direction of grain processing, etc., can solve the problems of high damage rate of parts, easy damage of gear roller bearings, and low material crushing ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

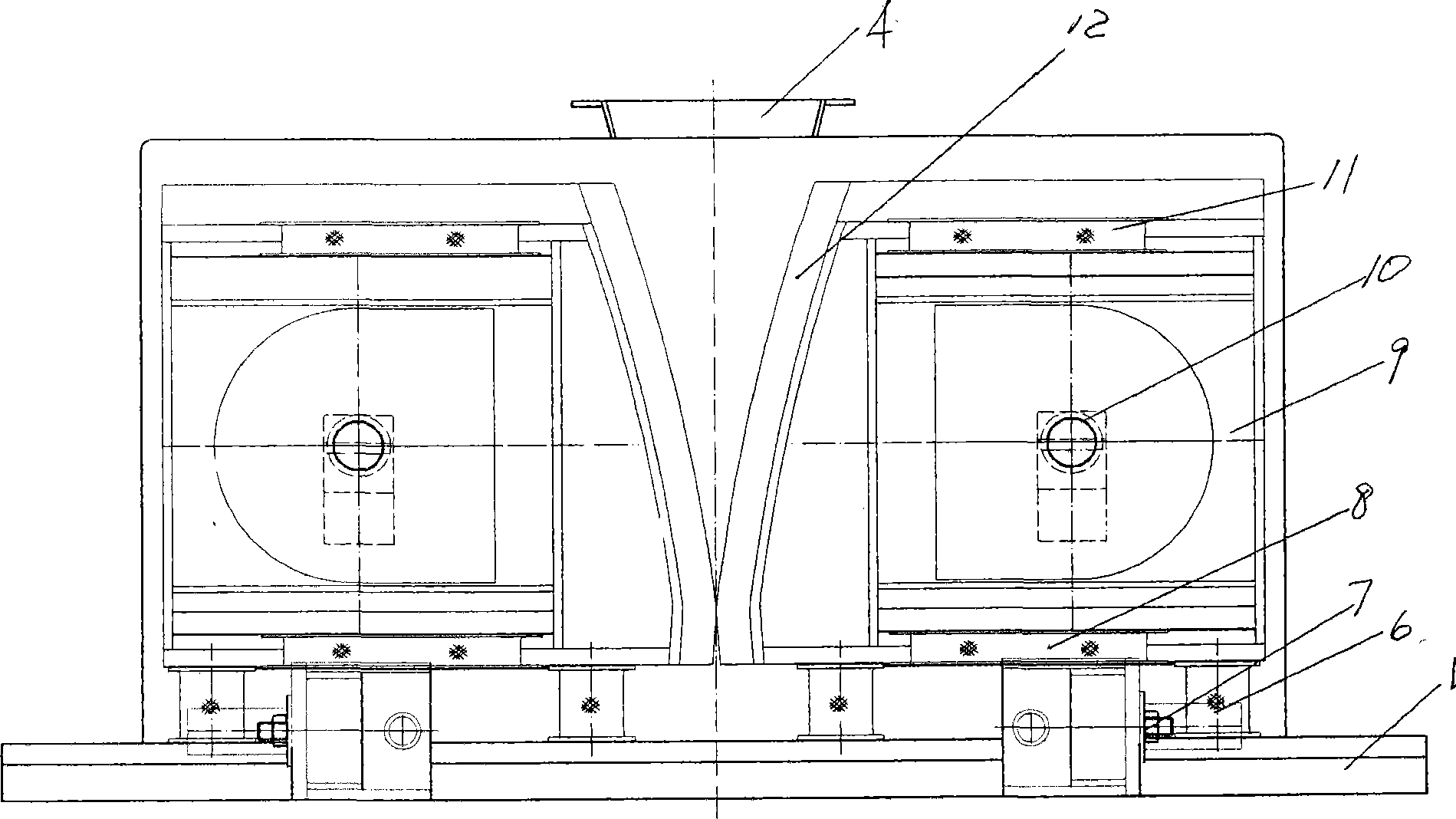

[0005] The present invention will be described in detail in conjunction with the above drawings. A pair of exciters 10 are respectively provided on the outside of the left and right jaw plates 12, and rubber leaf springs 8, 11 are provided between the upper and lower parts of the movable jaw 9 of the exciter and the machine body. , a rubber spring 6 is provided between the machine body and the machine base 1, and a cavity with a large upper part and a smaller lower part is formed between the two jaw plates. The upper end of the cavity is opposite to the feeding port 4, and the lower end is opposite to the discharging port. 1. The lower end of the movable jaw of the right vibrator is provided with an adjusting bolt 7 and a dial 5, which are used to adjust the size of the discharge port at the lower end of the jaw plate.

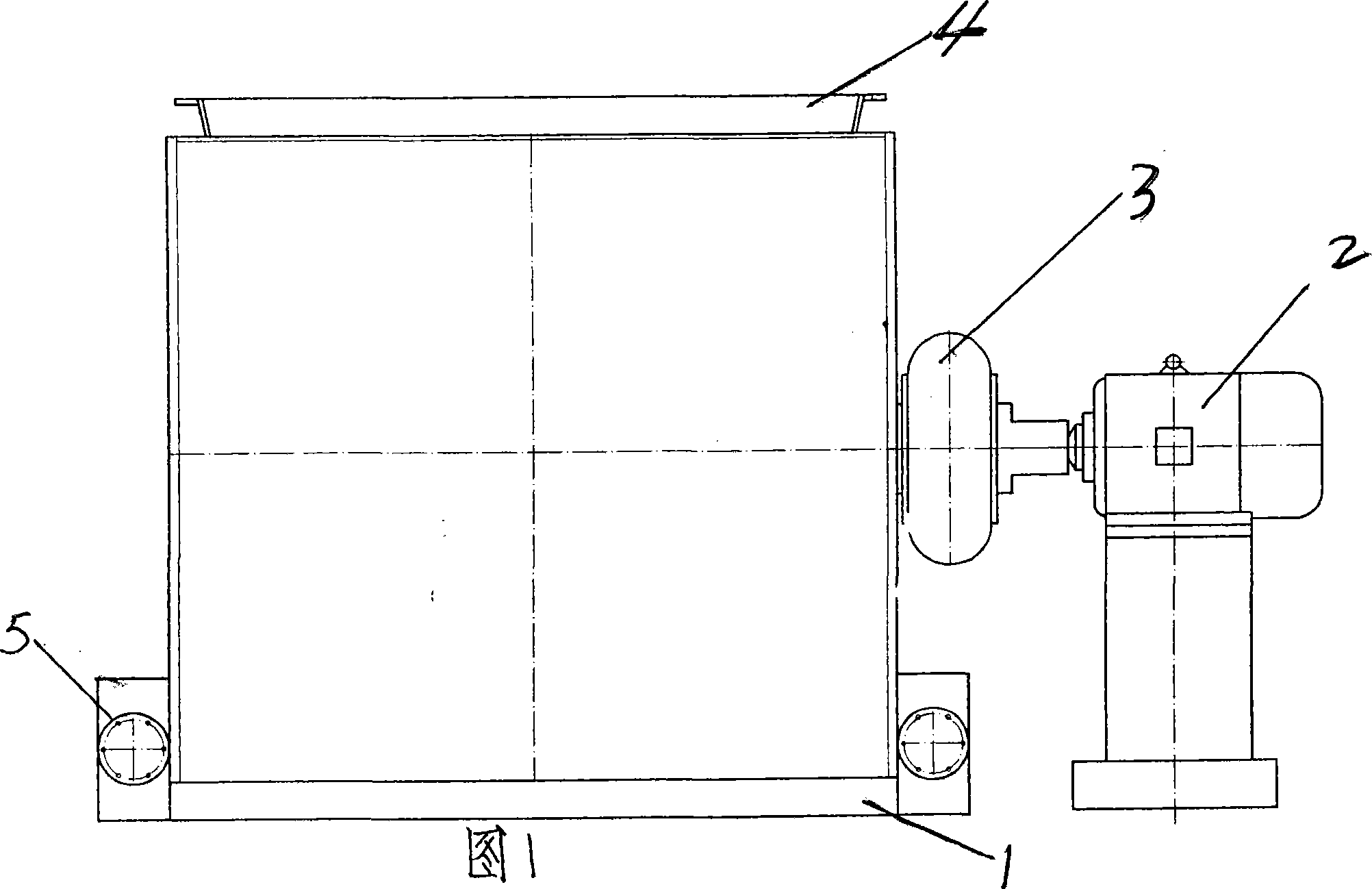

[0006] The two-mass vibrating crusher of the present invention adopts two ordinary motors 2 to respectively drive a vibrator through a flexible coupling 3 to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com