Guidable structure such as a catheter or an endoscope

A technology for manipulating structures and endoscopes, which is applied in the field of catheters or endoscope-type steerable structures, can solve the problems of inability to enter the machine, complicated inspection procedures, unsuitable for automatic control, etc., and achieve a good adjustment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

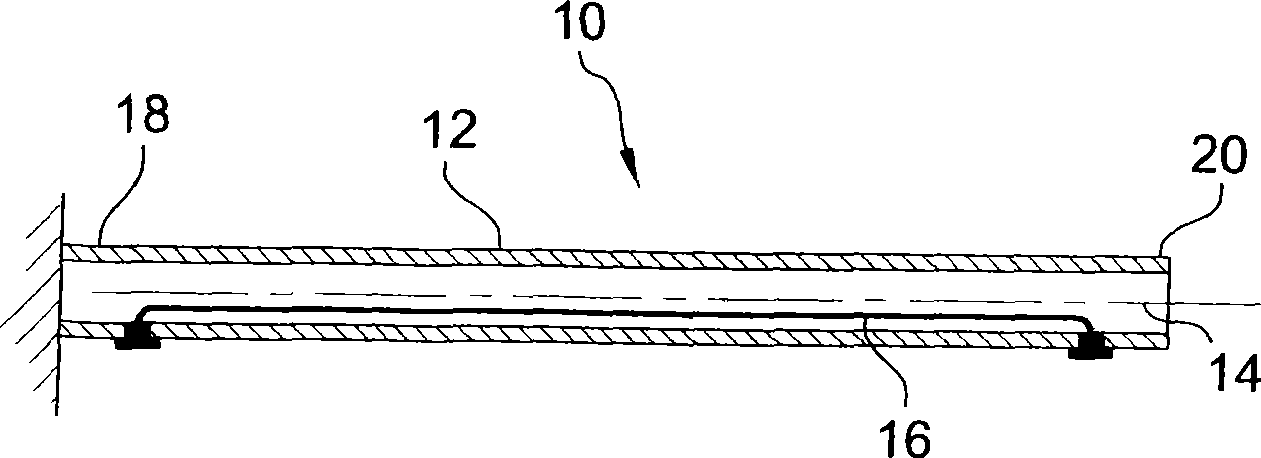

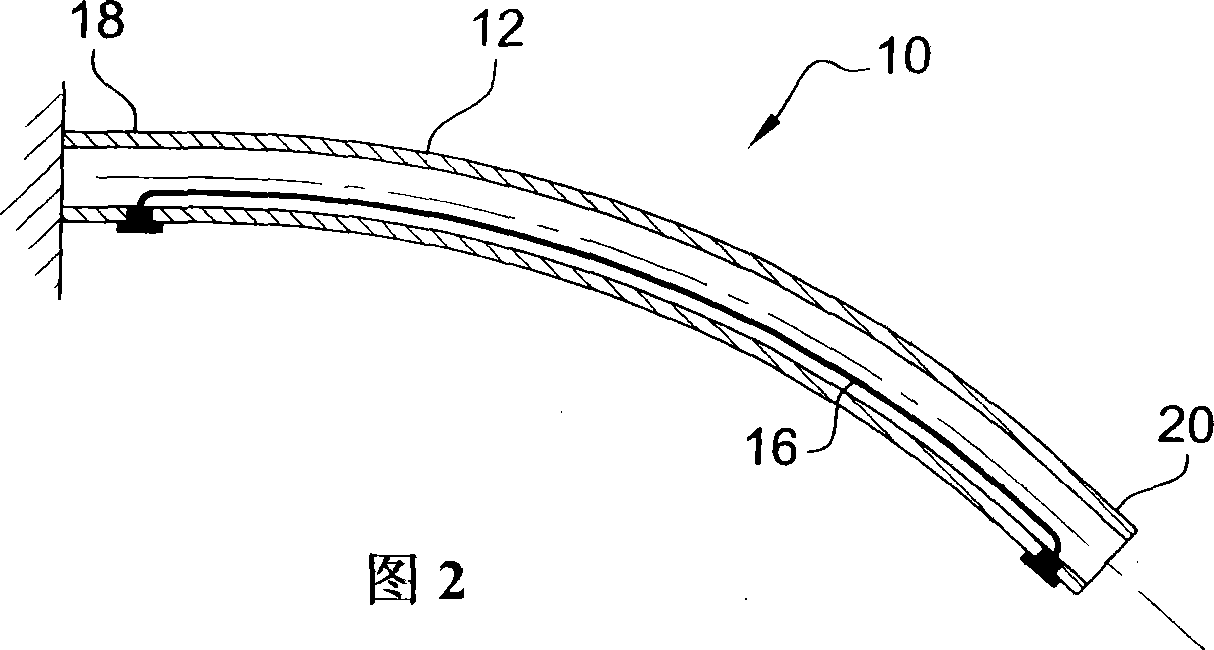

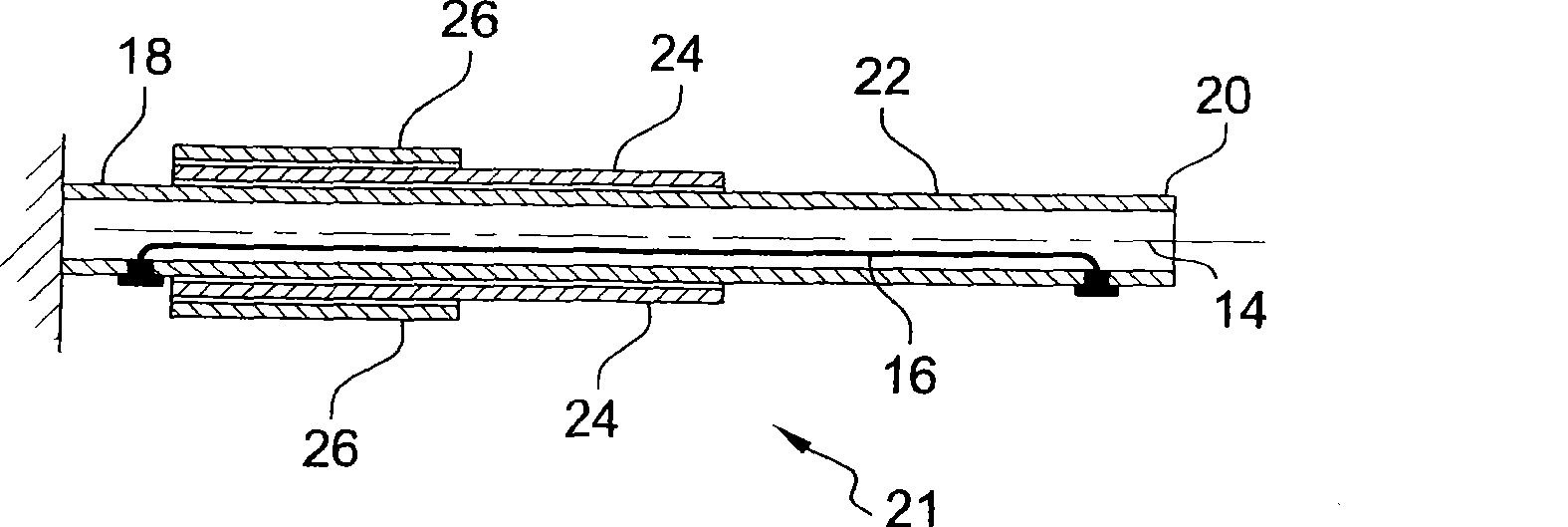

[0039] First refer to figure 1 , which shows a schematic diagram of a catheter or endoscopic steerable structure 10 according to the prior art, which includes a tubular flexible body 12 along a longitudinal axis 14, and includes a shrinkable material such as a shape memory alloy ( SMA) type—the actuator 16 is arranged along the tubular mechanism and its interior. The actuator is in the form of a metal wire and is connected to a power supply (not shown in the figure). The steerable structure 10 has a stationary proximal end 18 and a steerable distal end 20 .

[0040]Heating the shape-memory alloy (SMA) material through the Joule effect can cause the atoms that make up the wire to rearrange (when the activation temperature is reached), causing a contraction (response time of less than a second) that shortens its length. A wire 16 secured to the wall of the tubular structure 12 causes the distal end 20 of the tube to bend in a direction perpendicular to the axis 14 (Fig. 2). A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com