Apparatus for checking electronic type current mutual inductor

A technology of current transformer and calibration device, which is applied in the direction of measuring device, instrument, measuring electric variable, etc. Difficulty in acquisition and other problems, to overcome the long-term accuracy is not high enough, improve the working life, reduce the effect of white noise and DC components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

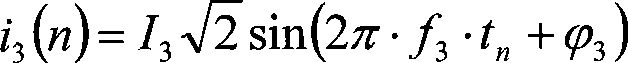

Method used

Image

Examples

Embodiment Construction

[0022] Such as figure 1 As shown, it is a schematic block diagram of the composition of the calibration device of the present invention, including a calibration system 1 and a self-calibration system 2, the calibration system 1 realizes the calibration function of the tested transformer 15, and the self-calibration system 2 realizes the calibration of the reference transformer 12 online self-calibration functions.

[0023] The calibration system 1 is composed of a first current source 11 , a reference transformer 12 , a merging unit 13 , a control computer 14 , and a transformer 15 under test. The connecting wire passes through the reference transformer 12 and the tested transformer 15 at the same time, so that the current signal A1 generated by the first current source 11 is simultaneously sensed by both. The reference transformer 12 and the tested transformer 15 are all connected to the merging unit 13, and the merging unit 13 outputs a synchronous pulse signal (5kHz) to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com