Centrifugal fan

A centrifugal fan and fan frame technology, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump devices, etc., can solve the problems of fan noise increase and discomfort, and reduce disturbance and noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

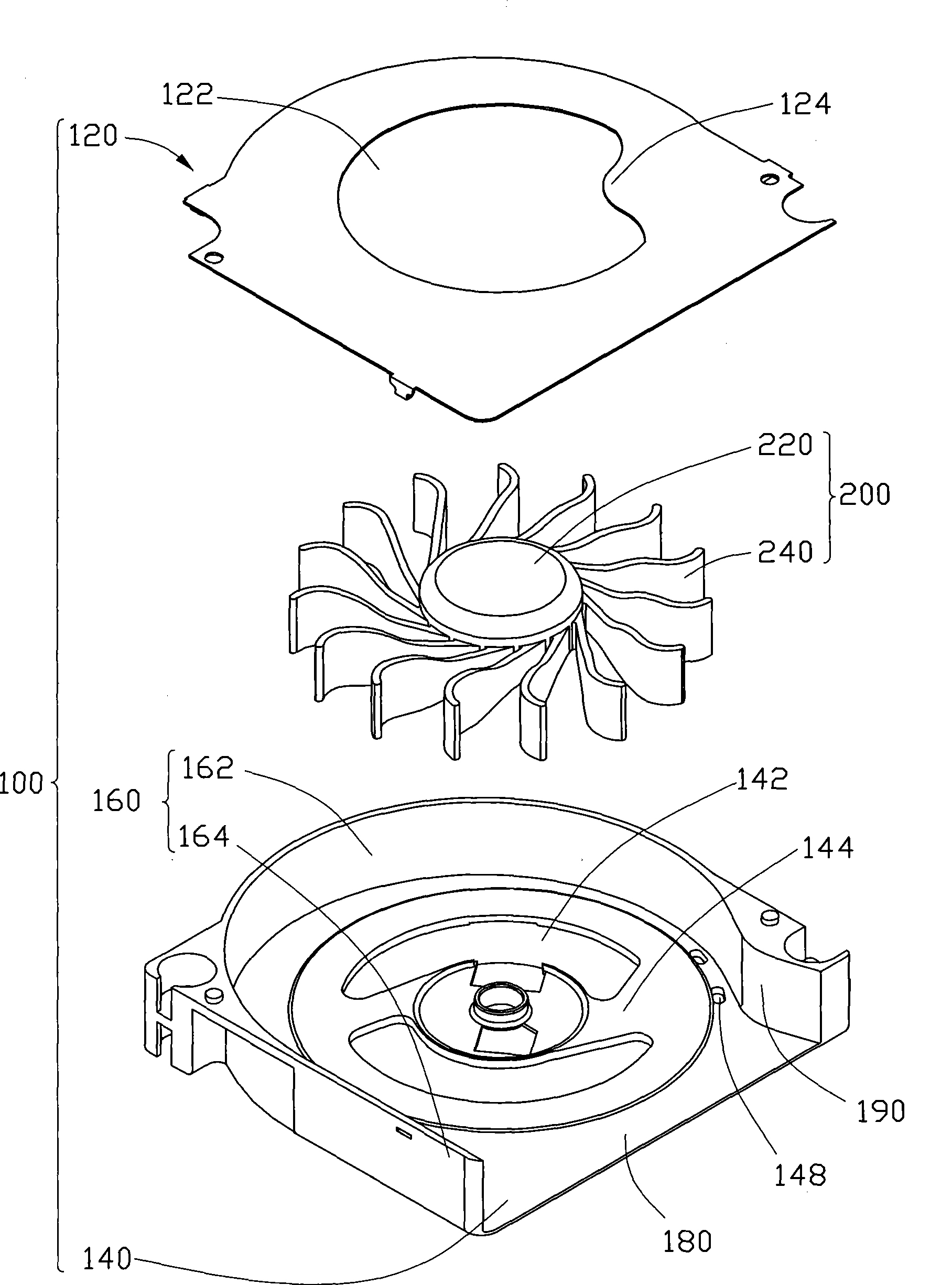

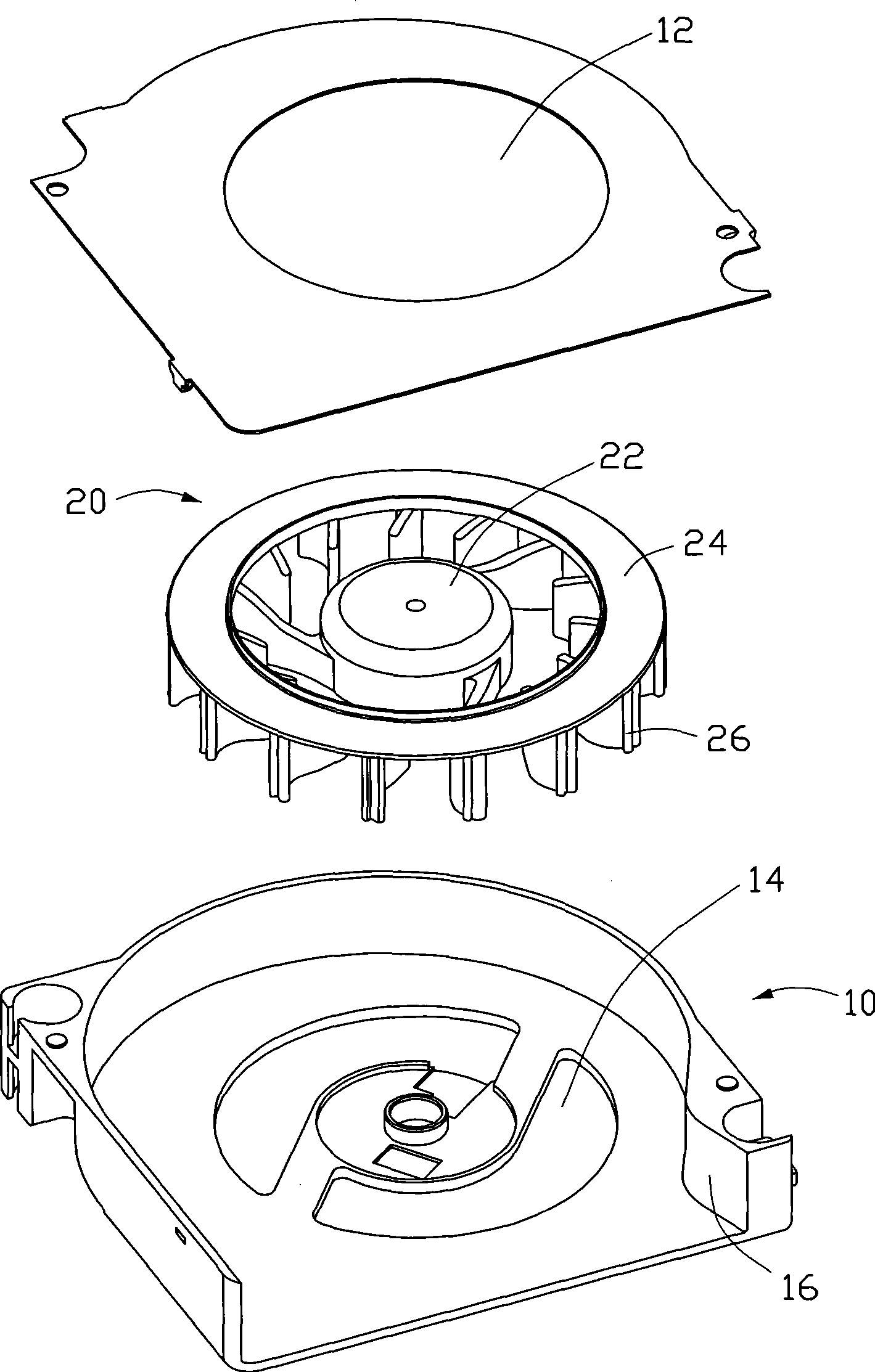

[0011] see figure 1 and figure 2 , are three-dimensional assembly and exploded views of a centrifugal fan according to a preferred embodiment of the present invention. The centrifugal fan can be combined with a heat dissipation device (not shown) to dissipate heat from heat-generating electronic components.

[0012] The centrifugal fan includes a fan frame 100 and an impeller 200 accommodated in the fan frame 100 . The impeller 200 includes a hub 220 and a plurality of blades 240 radially extending from the periphery of the hub 220 , the blades 240 are inclined clockwise, and the ends of the blades 240 are curved counterclockwise.

[0013] The fan frame 100 includes a cover plate 120 , a bottom plate 140 and a side wall 160 disposed between the cover plate 120 and the bottom plate 140 . Wherein, the side wall 160 is a semi-closed structure extending upward from the periphery of the bottom plate 140 , and includes an arc-shaped surface 162 and a straight surface 164 . An a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com