Sheet metal draw-out tool

A technology for appliances and sheet metal, applied in the field of sheet metal pulling appliances, can solve the problems of inconvenience of increasing operation, limited strength of pulling force, limitation of use range and strength of pulling force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation state of the sheet metal pulling tool of the present invention is described below in conjunction with the accompanying drawings, but the present invention is not limited to the following description of the implementation state.

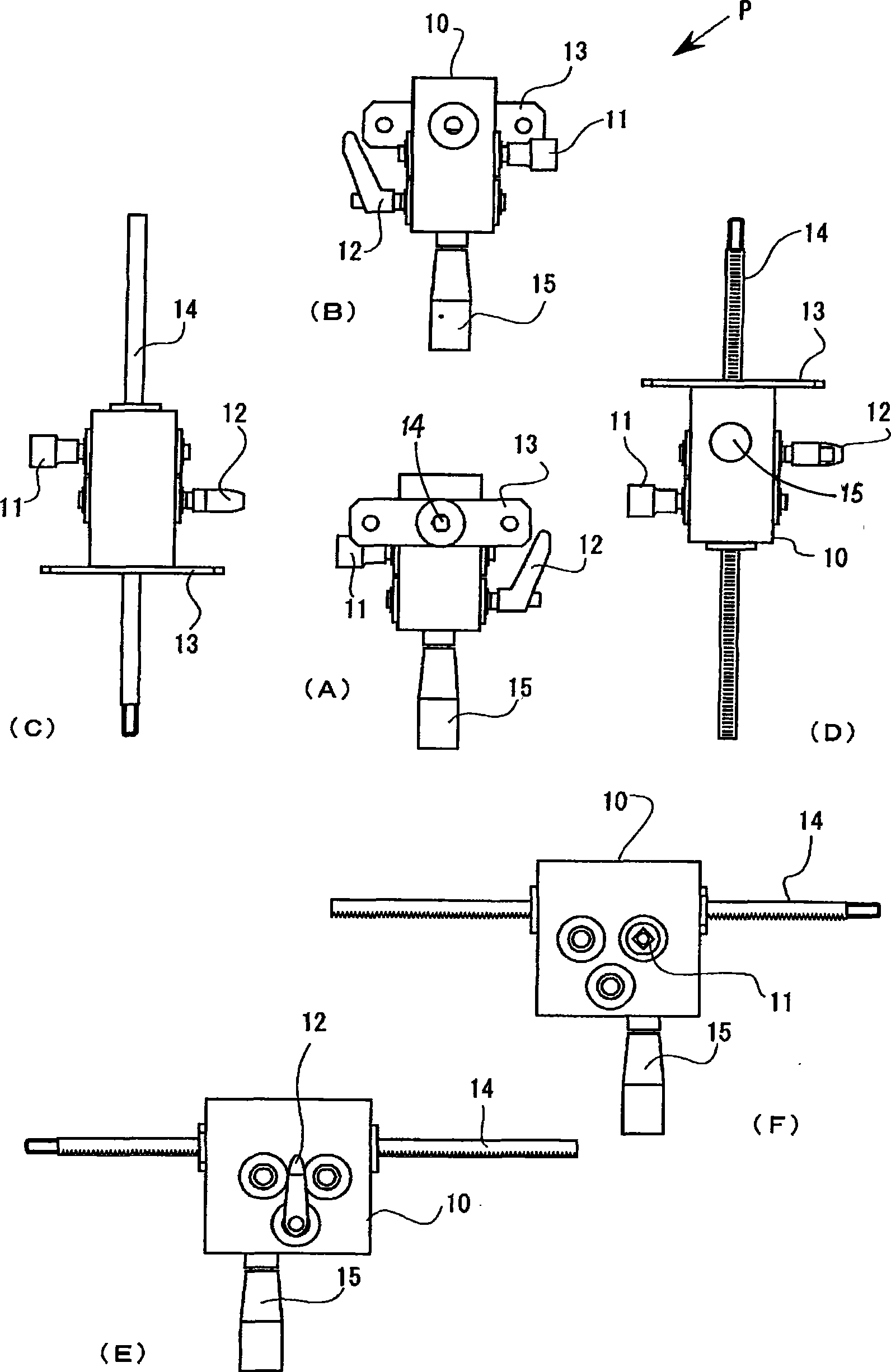

[0036] See attached figure 1 . This figure is a schematic diagram of the six-sided structure of the sheet metal pulling tool of the present invention. In the figure, (A) is a front view, (B) is a rear view, (C) is a top view, (D) is a bottom view, and (E) is a right view , (F) is the left view. A sheet metal pulling tool, comprising a stretcher shell 10, an external force introduction device 11, a stretching trigger 12, a support plate 13, a stretching shaft 14 and a handle 15; the front of the stretcher shell 10 is provided with a Rectangular support plate 13, stretching shaft 14 passes through whole stretcher housing 10 in parallel through support plate 13; The right outer end of the right side is connected with stretch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com