Turnip harvesting machine

A harvester and sugar beet technology, used in excavator harvesters, harvesters, topping machines, etc., can solve the problems of partial tool wear, time-consuming, blocking, etc., to avoid friction and wear loads, improve units, and increase productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

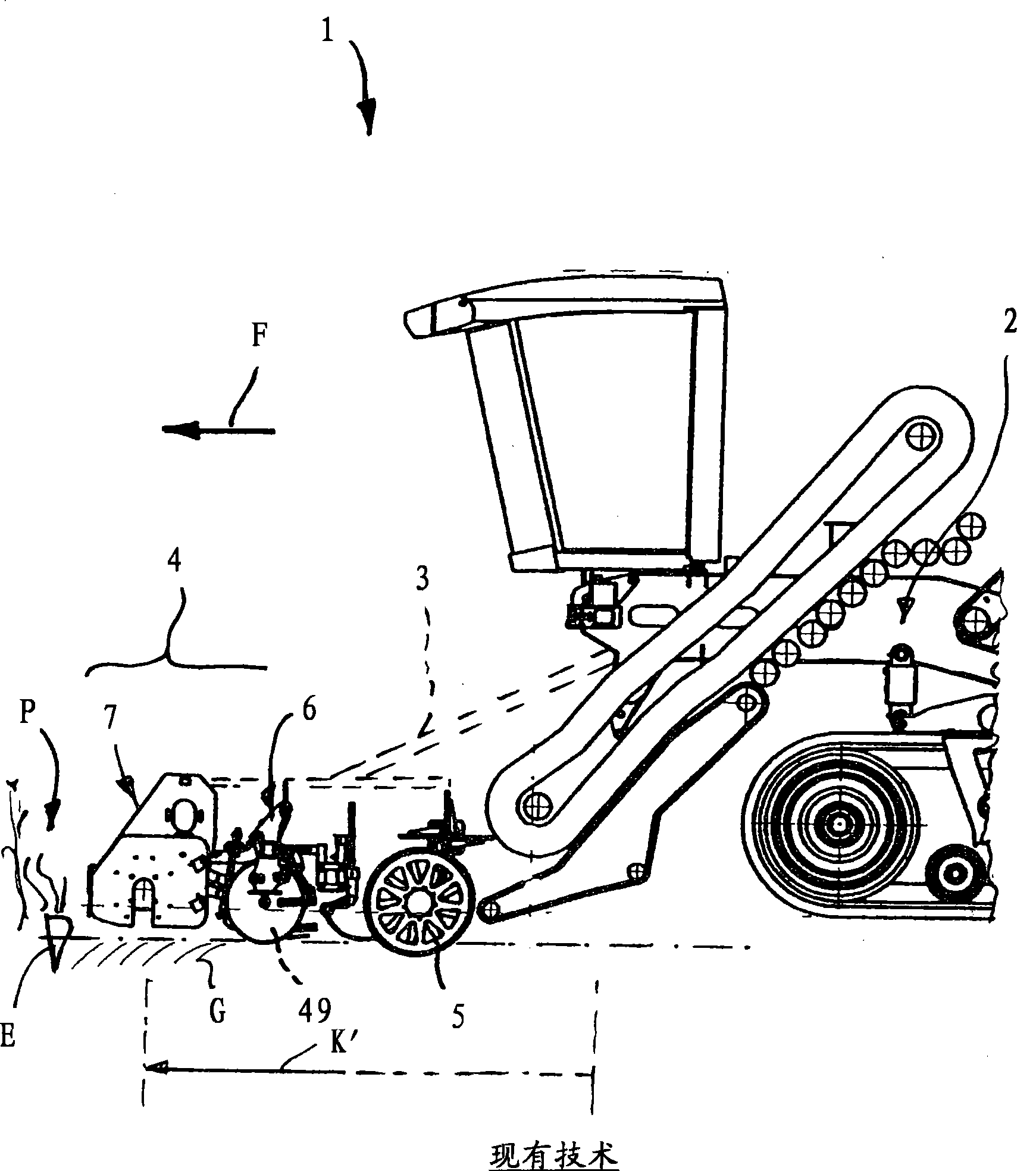

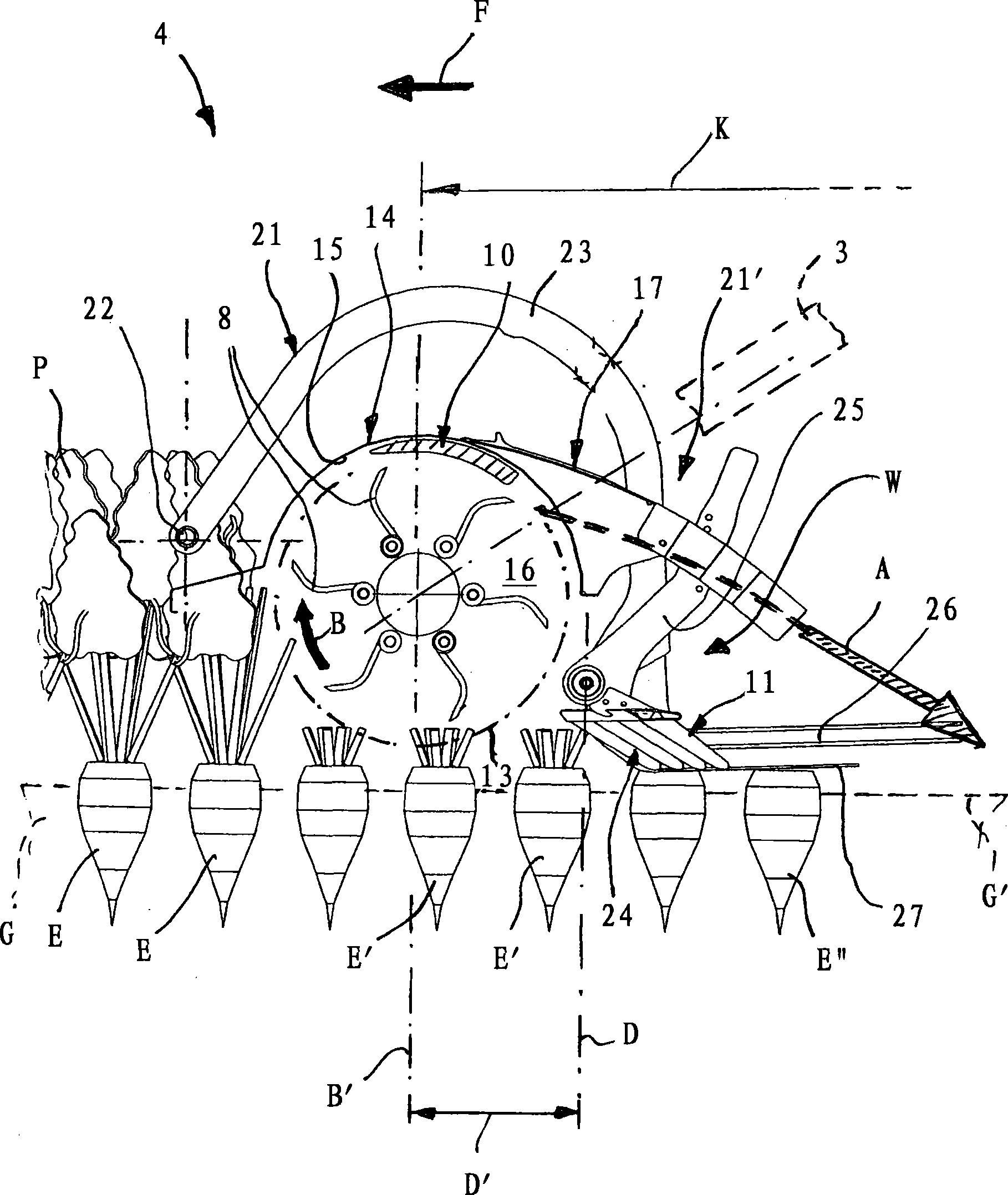

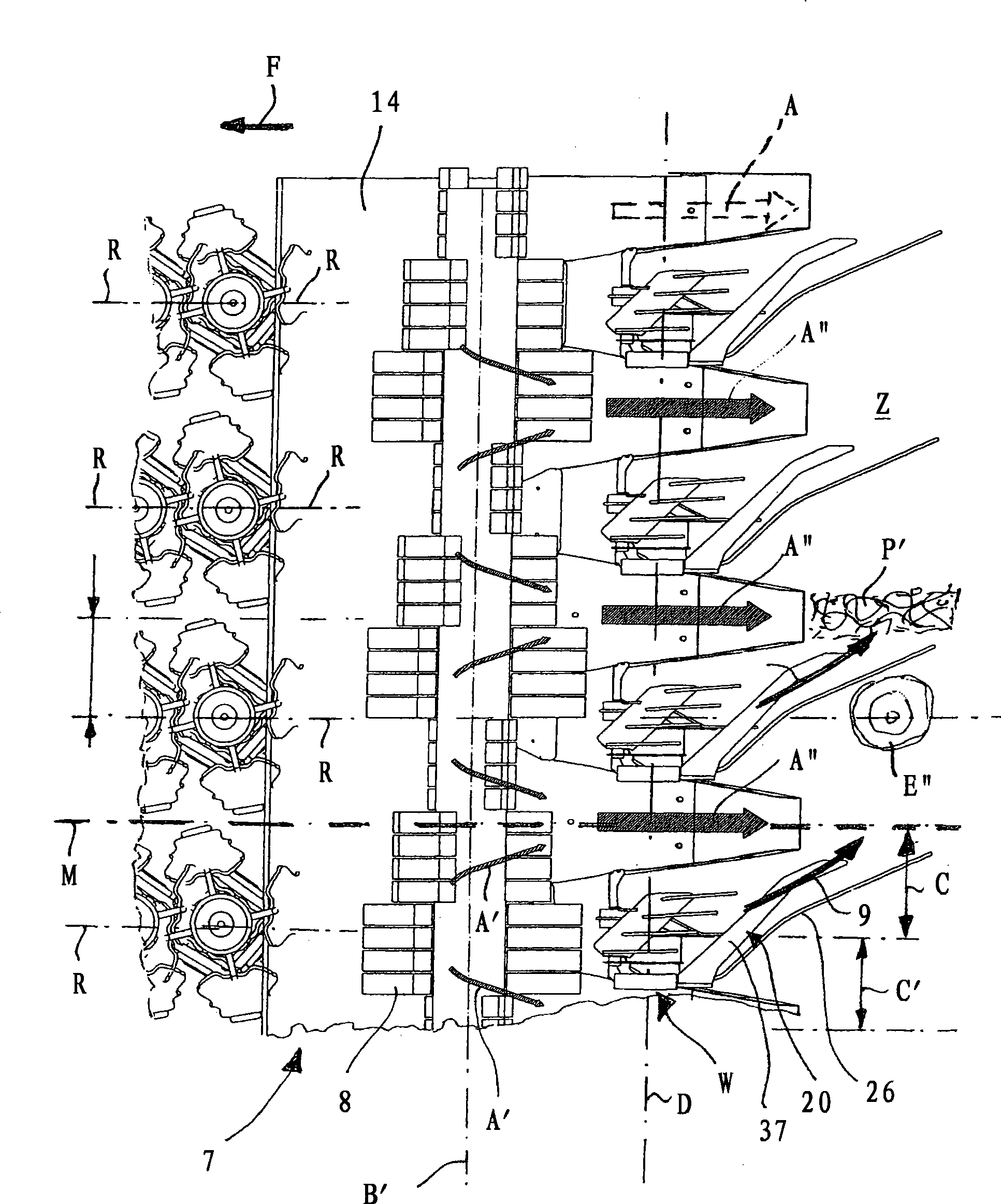

[0026] exist figure 1 A sugar beet harvester, generally designated 1 , in particular in the form of a harvester, is shown in a partial sectional view, on whose body frame 2 an excavator unit 4 held by a support element 3 not shown in detail is arranged. The sugar beet harvester 1 is marketed under the trademark "Maxtron 620" by the company Grimme (GrimmeLandmaschinenfabrik GmbH & Co. KG, Damme, Prospekt-Nr. Sugar is formed in the form of a beet harvester. In a machine 1 of this type, not only a cutting tool in the form of a topper 6 but also a cutting blade held upstream of the topper is provided in a multi-row arrangement in the direction of travel F in front of the respective digging plow share 5 (Rodescharen). machine7. Beet leaves, green growths (Grünwuchs) or similar plant parts P are removed from the crops growing in the ground G by a distance before the excavation process realized at reference number 5 in a known mobile guide device using a leaf cutter 7 Removal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com